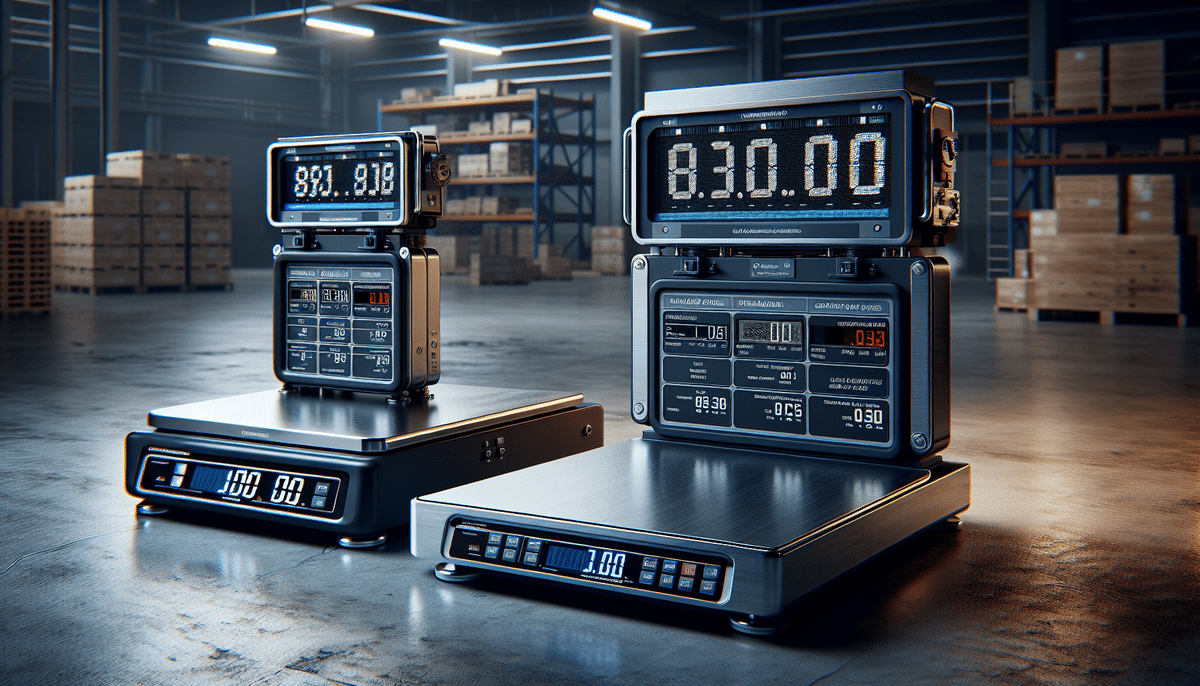

Introduction: Salter Brecknell PS1000 vs Rice Lake RoughDeck

Industrial scales are essential for accurately weighing heavy loads across various sectors, including manufacturing, logistics, and warehousing. Selecting the appropriate scale ensures precision, efficiency, and longevity in operations. The Salter Brecknell PS1000 and the Rice Lake RoughDeck are two prominent industrial scales that businesses frequently compare when seeking reliable weighing solutions. This article offers a comprehensive comparison of their features, specifications, performance, pricing, durability, pros and cons, user reviews, installation processes, and the importance of accurate weighing and proper maintenance. Our objective is to provide you with the necessary insights to make an informed decision when choosing an industrial scale for your operations.

Feature Comparison

Both the Salter Brecknell PS1000 and Rice Lake RoughDeck are designed for heavy-duty industrial weighing, yet they present distinct features catering to different operational demands.

- Design:

- PS1000: Features a low-profile design with a heavy-duty steel body resistant to corrosion and wear.

- RoughDeck: Offers a higher profile available in both steel and stainless steel constructions, providing flexibility for diverse environments.

- Display:

- PS1000: Equipped with a clear LED display for easy readability.

- RoughDeck: Utilizes a backlit LCD, enhancing visibility in various lighting conditions.

- Power Supply:

- PS1000: Includes a built-in rechargeable battery and an AC adapter, offering both portability and stationary use.

- RoughDeck: Requires an external power source, which may necessitate additional setup.

- Environmental Configuration:

- RoughDeck: Customizable for use in dry or wet conditions and hazardous or non-hazardous areas, making it versatile for specialized industrial settings.

These distinctions emphasize how each scale can be tailored to specific industrial applications based on required durability, flexibility, and display preferences.

Specifications

Understanding the technical specifications of each scale is crucial to determine the best fit for your business needs. Below is a detailed comparison:

- Maximum Capacity:

- PS1000: 1,000 lbs

- RoughDeck: Ranges from 2,500 lbs to 10,000 lbs

- Weighing Increments:

- PS1000: 0.5 lbs

- RoughDeck: Between 0.5 lbs and 2 lbs, depending on the model

- Platform Size:

- PS1000: 4 ft x 4 ft

- RoughDeck: Ranges from 4 ft x 4 ft to 5 ft x 7 ft

- Display Accuracy:

- PS1000: ±0.1% of applied load

- RoughDeck: Up to ±1% of applied load

- Construction Materials:

- PS1000: Steel frame with a diamond plate steel platform

- RoughDeck: Steel channel frame with a tread plate steel platform

- Power Supply:

- PS1000: Built-in rechargeable battery and AC adapter

- RoughDeck: Requires an external power source

Key Insights:

- The PS1000 is ideal for businesses with lower weight requirements and offers higher display accuracy.

- The RoughDeck is suitable for environments needing higher capacity and larger platform sizes, albeit with slightly lower display accuracy.

- Power requirements differ, with the PS1000 offering more portability options.

Performance Comparison

The performance of an industrial scale is critical for ensuring reliable and accurate weight measurements essential for various business operations. Both the Salter Brecknell PS1000 and the Rice Lake RoughDeck have demonstrated robust performance in their respective applications, each with unique advantages:

- Load Handling:

- PS1000: The low-profile design makes it suitable for smaller loads and environments with limited space.

- RoughDeck: Capable of handling larger loads with its higher profile design, accommodating heavier items efficiently.

- Accuracy:

- Both scales offer high accuracy levels, essential for precision weighing in sectors like pharmaceuticals and food production.

- Platform Size:

- PS1000: The smaller platform size is ideal for compact operational areas.

- RoughDeck: Larger platform options cater to businesses requiring more extensive weighing surfaces.

- Durability:

- PS1000: The stainless steel platform resists corrosion and physical damage, ensuring longevity in standard environments.

- RoughDeck: Rugged steel construction designed to endure exposure to corrosive agents and contaminants, ensuring extended service life.

Conclusion on Performance: The PS1000 is optimal for businesses with space constraints and lighter load requirements, while the RoughDeck excels in environments that demand handling of heavier loads and exposure to more demanding conditions.

Price Comparison

Budget considerations are paramount when investing in an industrial scale. Both the Salter Brecknell PS1000 and the Rice Lake RoughDeck are positioned as premium heavy-duty scales, reflecting their durability and advanced features.

- Salter Brecknell PS1000:

- Starting Price: Approximately $1,000

- Ideal for businesses seeking a cost-effective solution without compromising on basic durability and accuracy.

- Rice Lake RoughDeck:

- Price Range: $2,000 to $6,000

- The higher cost is justified by the scale's extended load capacity, advanced features, and customizable options.

Additional Considerations:

- Load Capacity: The PS1000 accommodates up to 1,000 lbs, whereas the RoughDeck supports up to 10,000 lbs, making the RoughDeck suitable for businesses dealing with significantly larger and heavier items.

- Readability: The PS1000 offers a readability of 0.5 lbs, providing more precise measurements, whereas the RoughDeck's readability is 1 lb, which may suffice for less precision-intensive applications.

When evaluating the price, it is essential to balance initial costs with long-term benefits and operational needs, ensuring that the chosen scale aligns with both current and future business requirements.

Durability Comparison

Durability is a crucial factor in selecting industrial scales, as these devices must endure rigorous use and often harsh environmental conditions.

- Construction Quality:

- PS1000: Built with a robust steel frame and diamond plate steel platform, offering resistance to corrosion and physical wear.

- RoughDeck: Features a rugged steel channel frame and tread plate steel platform, engineered to withstand exposure to corrosive agents and contaminants.

- Environmental Resilience:

- PS1000: Suitable for standard industrial environments, though not specifically rated for extreme or hazardous conditions.

- RoughDeck: Designed to operate reliably in a variety of demanding environments, including areas exposed to moisture, chemicals, or heavy contamination.

- Maintenance Needs:

- PS1000: Requires standard maintenance practices to preserve its durability and accuracy over time.

- RoughDeck: Enhanced durability reduces the frequency of repairs and maintenance, making it a low-maintenance option for high-use settings.

- Portability:

- PS1000: Designed to be compact and lightweight, facilitating ease of movement and storage.

- RoughDeck: Its larger and heavier build makes it more suitable for fixed installations where portability is not a primary concern.

Conclusion on Durability: The RoughDeck offers superior durability and environmental resilience, making it the preferred choice for businesses operating in more challenging conditions. Conversely, the PS1000 provides adequate durability for standard industrial settings and benefits from greater portability.

Pros and Cons

Evaluating the advantages and disadvantages of each scale assists in making a balanced decision tailored to your business needs:

Salter Brecknell PS1000

- Pros:

- Affordable pricing, making it accessible for budget-conscious businesses.

- Compact and lightweight design enhances portability and ease of installation.

- High display accuracy (±0.1% of load) for precise measurements.

- Built-in rechargeable battery offers flexibility for both portable and stationary use.

- Cons:

- Limited maximum capacity (1,000 lbs) may not suffice for heavy-duty applications.

- Not ideal for use in wet or highly corrosive environments.

- Lacks advanced features such as data storage and printing capabilities.

Rice Lake RoughDeck

- Pros:

- Higher load capacity (up to 10,000 lbs) accommodates larger and heavier items.

- Advanced features including data storage, printing, and customizable configurations enhance functionality.

- Durable construction suitable for harsh and corrosive environments.

- Multiple platform size options provide flexibility for various operational needs.

- Cons:

- Higher initial cost may be prohibitive for smaller businesses or those with limited budgets.

- Larger and heavier design limits portability and requires more substantial installation space.

Summary: The PS1000 is ideal for businesses seeking a cost-effective, portable scaling solution with high precision for lighter loads. In contrast, the RoughDeck offers enhanced capacity, durability, and advanced features suitable for demanding industrial environments, albeit at a higher price point.

User Reviews

Customer feedback offers valuable insights into the real-world performance and satisfaction associated with industrial scales. Both the Salter Brecknell PS1000 and the Rice Lake RoughDeck have received positive reviews, highlighting their respective strengths:

Salter Brecknell PS1000

- Affordability: Many users appreciate the PS1000 as a cost-effective solution that delivers reliable performance without a hefty price tag.

- Reliability: Customers consistently report dependable operation and accurate measurements, essential for maintaining operational integrity.

- Ease of Use: The user-friendly interface and straightforward design facilitate quick training and efficient usage.

- Portability: The lightweight and compact nature of the PS1000 is praised for its ease of movement and flexible installation options.

Rice Lake RoughDeck

- Customization: Users value the customizable configurations that allow the scale to adapt to specific industrial environments and requirements.

- Advanced Features: The inclusion of data storage and printing capabilities is appreciated for enhancing operational workflows and record-keeping.

- Durability: Customers commend the rugged build quality, noting that the RoughDeck withstands harsh conditions and heavy usage without compromising performance.

- Capacity: The ability to handle substantial loads is frequently highlighted, making it suitable for heavy-duty industrial applications.

Overall Satisfaction: Both scales receive high marks within their respective niches. The PS1000 is favored for its affordability and reliability in standard applications, while the RoughDeck is preferred by users who require higher capacities and customization to meet specialized industrial needs.

Installation Comparison

The ease of installation can significantly impact both the initial setup time and overall operational readiness. Here's how the PS1000 and RoughDeck compare:

- Salter Brecknell PS1000:

- Ease of Installation: Designed for straightforward setup due to its lightweight and compact, low-profile design.

- Time Required: Minimal installation time, allowing businesses to deploy the scale quickly without extensive downtime.

- Installation Support: Typically includes user-friendly manuals and responsive customer support to assist with any setup inquiries.

- Rice Lake RoughDeck:

- Ease of Installation: More complex installation process owing to its larger size and higher weight capacity.

- Time Required: Installation may require additional time and resources, including potential need for specialized equipment or professional assistance.

- Installation Support: Comprehensive installation guides and manufacturer support are available to facilitate the setup process.

Recommendation: If quick and hassle-free installation is a priority, the PS1000 is advantageous. However, for businesses that can accommodate a more involved setup process, the RoughDeck provides robust capabilities post-installation.

The Importance of Accurate Weighing in Industrial Settings

Precision in weighing is vital across various industrial sectors, directly impacting operational efficiency, regulatory compliance, and financial performance. Here's why accurate weighing matters:

- Inventory Management: Ensuring accurate measurements of raw materials and finished products aids in maintaining optimal inventory levels, reducing the risk of overstocking or stockouts.

- Cost Control: Accurate weighing minimizes financial losses by preventing overbilling or underutilization of materials, thereby maintaining profitability.

- Regulatory Compliance: Many industries are subject to strict weight-based regulations. Accurate scales help businesses adhere to these standards, avoiding legal repercussions and fines.

- Quality Assurance: Consistent and precise weight measurements are essential for maintaining product quality and meeting customer expectations.

- Production Efficiency: Reliable data from accurate scales facilitates effective production planning and control, enhancing overall workflow and productivity.

Implementing dependable industrial scales like the Salter Brecknell PS1000 or the Rice Lake RoughDeck is instrumental in achieving these objectives, ensuring that your business operations are both accurate and efficient.

Proper Maintenance Tips for Longevity of Your Industrial Scale

Regular maintenance of your industrial scale is essential to preserve its accuracy, reliability, and lifespan. Here are key maintenance practices:

- Regular Calibration:

- Calibrate the scale periodically to ensure measurement precision. Refer to the manufacturer's guidelines for calibration intervals and procedures.

- Routine Cleaning:

- Keep the weighing platform and display areas clean from dust, debris, and spills to prevent operational interferences and physical wear.

- Protect from Contaminants:

- Guard the scale against exposure to corrosive agents, moisture, and contaminants that can degrade materials and electronic components.

- Prevent Overloading:

- Avoid exceeding the scale's maximum capacity to prevent structural damage and ensure consistent performance.

- Follow Manufacturer's Guidelines:

- Adhere to all usage and maintenance recommendations provided by the manufacturer to maintain warranty coverage and optimal functioning.

- Regular Inspections:

- Conduct periodic inspections to identify and address any signs of wear, damage, or malfunction early.

Additional Tips:

- Ensure that the scale is placed on a stable and level surface to maintain accuracy.

- Limit the scale's exposure to extreme temperatures, which can affect electronic components and overall performance.

- Store any accessories or components in designated areas to prevent loss or damage.

Implementing these maintenance strategies will enhance the durability and consistent performance of your industrial scale, ultimately contributing to sustained business efficiency and accuracy in operations.