Simplifying Billable Weight: A Comprehensive Guide

As a business owner or logistics manager, understanding billable weight is essential for managing shipping costs effectively. This comprehensive guide delves into both the fundamental and advanced concepts of billable weight, enabling you to accurately calculate and minimize your shipping expenses.

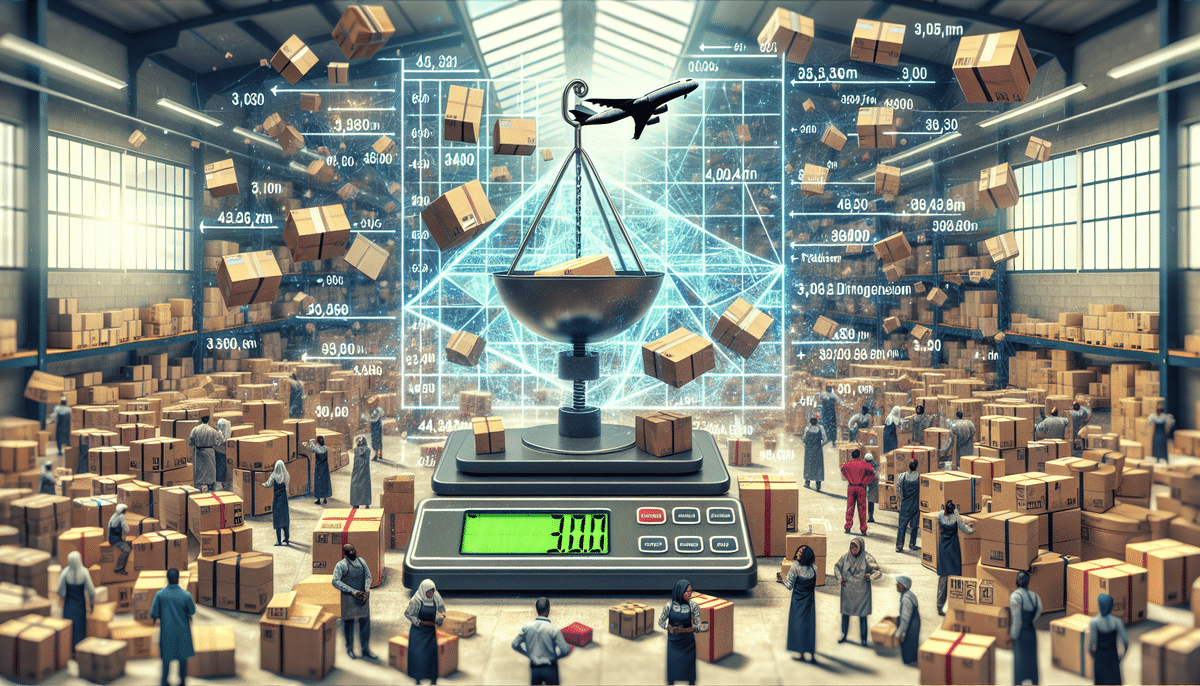

Understanding the Concept of Billable Weight

Billable weight is the metric used by shipping carriers to determine the cost of transporting goods. It is calculated as the greater of the actual weight or dimensional (DIM) weight of a package. DIM weight is derived by multiplying the length, width, and height of a package and then dividing by a dimensional factor set by the shipping carrier.

For instance, if a package weighs 10 pounds but has a DIM weight of 15 pounds, the carrier charges based on the 15-pound DIM weight. This pricing approach accounts for the space a package occupies, influencing the carrier's fuel and operational costs.

Different shipping carriers may employ varying dimensional factors when calculating DIM weight. Consequently, the same package could incur different billable weights and costs depending on the chosen carrier. It's crucial to verify each carrier's specific dimensional factor and billable weight calculation method to ensure accurate shipping cost estimations.

According to the 2023 Shipping Industry Report, optimizing billable weight can lead to significant cost savings, with businesses reporting reductions in shipping expenses by up to 20%.

How to Calculate Billable Weight Accurately

Accurate calculation of billable weight involves determining both the actual weight and DIM weight of your packages:

- Actual Weight: Use a reliable scale capable of measuring the weight of your goods precisely.

- DIM Weight: Measure the package dimensions in inches, multiply length by width by height to obtain the volume, and then divide by the carrier's dimensional factor.

For example, with a carrier using a dimensional factor of 139, a package measuring 10 x 10 x 10 inches would have a DIM weight of (10 x 10 x 10) / 139 ≈ 7.19 pounds.

Bear in mind that carriers may have different dimensional factors and minimum billable weights. Some carriers enforce minimum weights, meaning packages lighter than the minimum threshold are billed at that minimum weight regardless of their actual weight.

Additionally, the shipment type—such as air freight versus ground or ocean freight—can influence weight restrictions and charges. Understanding each shipment type's specific requirements and fees is vital for accurate billable weight calculations and avoiding unexpected costs.

For more detailed methodologies, refer to the DIM Weight Calculator Guidelines provided by industry experts.

Factors that Affect Billable Weight

Several factors influence the billable weight of your shipments:

- Actual Weight: The physical weight of the package.

- Package Size and Volume: Larger packages may result in higher DIM weights.

- Transportation Mode: Air freight often has different weight assessments compared to truck or sea transport.

- Shipping Distance and Destination: Longer distances and international destinations can affect shipping costs and methodologies.

Packaging materials also play a role; heavier materials like metal can increase the billable weight, while lightweight alternatives like bubble wrap or foam can help reduce it. Furthermore, seasonal demand fluctuations, such as the holiday season, may prompt carriers to prioritize DIM weight over actual weight due to space constraints, leading to higher billable weights.

Research from the FreightWaves highlights that efficient packaging strategies can mitigate increased costs during peak seasons.

Different Methods of Calculating Billable Weight

Shipping carriers may use various methods to determine billable weight:

- Gross Weight Method: Calculates shipping costs based on the total weight, including the package and its contents.

- DIM Weight Method: Uses the dimensional weight to assess shipping costs.

- Cubic Capacity Method: Suitable for large shipments, this method bases costs on the shipment's overall size and volume.

Since different shipping companies may prefer different calculation methods, it's advisable to consult with your chosen carrier to understand their specific approach and its impact on your shipping costs.

For a comparative analysis of these methods, refer to the Shipping Calculation Methods Guide.

How to Reduce Billable Weight and Save Costs

Minimizing billable weight can lead to substantial shipping cost reductions. Strategies include:

- Utilizing Lightweight Packaging: Opt for materials that protect your goods without adding unnecessary weight.

- Consolidating Shipments: Combine multiple small packages into larger, more efficient shipments.

- Eliminating Excess Packaging: Remove any unnecessary packing materials or void space within packages.

- Choosing Alternative Transportation: Select ground transportation over air freight when feasible to reduce costs.

Optimizing package dimensions by selecting the smallest suitable packaging can decrease both weight and dimensional factors. Employing a shipping calculator can help compare rates and identify the most cost-effective shipping options for your business.

According to the Logistics Management, businesses that implement packaging optimization strategies can achieve up to a 15% reduction in shipping expenses.

Common Mistakes to Avoid When Calculating Billable Weight

Inaccuracies in billable weight calculations can lead to inflated shipping costs. Common pitfalls include:

- Incorrect Dimension Measurements: Ensure precise measurement of package dimensions to avoid discrepancies.

- Using Incorrect Dimensional Factors: Always verify the dimensional factor used by your carrier.

- Misunderstanding Carrier Rules: Familiarize yourself with carrier-specific weight restrictions and guidelines.

Additionally, overlooking potential extra charges—such as fuel surcharges, residential delivery fees, or handling fees—can result in unexpected costs. Reviewing your carrier's pricing structure comprehensively can help prevent these issues.

For more insights, explore the Common Mistakes in Shipping by industry experts.

Tips for Optimizing Shipping and Reducing Billable Weight

Enhance your shipping efficiency and lower billable weights with these tips:

- Leverage Shipping Platforms: Utilize platforms that compare rates and services from multiple carriers to find the best deals.

- Negotiate Rates: Use accurate billable weight data to negotiate more favorable shipping rates with carriers.

- Monitor Billable Weights: Track and manage your billable weights regularly to identify opportunities for improvement.

- Implement Predictive Analytics: Use data-driven insights to optimize your supply chain logistics.

Choosing lightweight and compact packaging materials not only reduces billable weight but also supports sustainability efforts by minimizing the environmental impact of shipping. Implementing eco-friendly packaging solutions can further enhance your company's green credentials.

Refer to the Environmental Shipping Optimization guidelines for sustainable packaging strategies.

The Impact of Packaging on Billable Weight

The selection and quantity of packaging materials significantly influence a shipment's billable weight. Employing lightweight materials such as bubble wrap, air pillows, or paper fillers can decrease package weight without compromising product safety during transit. Conversely, excessive use of heavy materials like metal or oversized boxes can increase both actual and DIM weights.

Moreover, considering the environmental implications of your packaging choices is crucial. Opting for biodegradable or recyclable materials not only reduces shipment weight but also aligns with sustainability goals by lowering your carbon footprint.

The Sustainable Packaging Initiative provides comprehensive resources on selecting eco-friendly packaging options that benefit both your business and the environment.

How to Negotiate Better Rates Based on Accurate Billable Weights

Securing more favorable shipping rates involves presenting accurate and detailed shipping data, including precise billable weights. Leveraging historical shipping data can empower you to negotiate lower rates with your carriers. Additionally, comparing rates through shipping platforms can help you identify the most competitive options.

Optimizing packaging to reduce weight and dimensions can further bolster your negotiation position, as it demonstrates efforts to minimize costs. Committing to higher shipment volumes or entering long-term contracts with carriers can also provide leverage for better rate agreements.

The Shipping Negotiation Tips guide offers strategies for effectively negotiating with carriers based on accurate shipping data.

Best Practices for Managing and Tracking Billable Weights

Effective management and tracking of billable weights are essential for maintaining shipping cost efficiency. Implement the following best practices:

- Staff Training: Educate your team on accurate measurement and calculation of billable weights.

- Utilize Software Solutions: Employ software or spreadsheets to systematically track billable weight data.

- Regular Data Reviews: Periodically assess your billable weight data to identify trends and areas for improvement.

Transparent communication with clients regarding how billable weights are calculated can foster trust and reduce billing disputes. Additionally, implementing quality control measures, such as using calibrated scales and conducting periodic audits, ensures the accuracy of your weight measurements.

For a detailed approach, consult the Best Practices for Billable Weight Management resource.

Real-life Examples of How Companies Have Simplified Their Billing Process Through Accurate Billable Weight Calculations

Numerous companies have streamlined their billing processes and reduced shipping costs by implementing precise billable weight calculations:

- A furniture company achieved a 12% reduction in shipping costs by consolidating smaller shipments into larger ones and optimizing their billable weights.

- A retail business lowered their shipping expenses by 20% by adopting lightweight packaging materials and negotiating better rates based on accurate billable weight data.

These success stories underscore the importance of meticulous billable weight management in enhancing overall business efficiency.

Future Trends in the Billing Industry and How They May Impact Billable Weight Calculations

The billing industry is evolving, with emerging trends poised to influence billable weight calculations:

- Technological Advancements: Innovations in transportation management systems (TMS) are enhancing the ability to track and manage billable weights across diverse carriers seamlessly.

- Environmental Regulations: Increasing environmental regulations may encourage carriers to adopt practices that reduce shipment weights to lower fuel consumption and emissions.

- Automation and AI: The integration of artificial intelligence in logistics can optimize packaging and shipment planning, further refining billable weight calculations.

Staying abreast of these trends enables businesses to adapt proactively, ensuring continued cost-efficiency and compliance with industry standards.

The Future of Shipping Trends report offers comprehensive insights into upcoming changes in the billing and shipping industries.

Frequently Asked Questions About Billable Weight Answered

Q: Can I use my own dimensional factor to calculate billable weight?

A: No, each carrier has its own dimensional factor based on their equipment capacity and operational costs. Utilizing an incorrect dimensional factor can result in inaccurate billing and additional fees.

Q: How can I avoid additional fees from my carrier?

A: Thoroughly review your carrier's rules and restrictions, including weight and size limits, before shipping. Accurately calculating your billable weight is also essential to prevent unexpected fees.

Q: Can I negotiate better shipping rates based on accurate billable weight data?

A: Yes, providing carriers with precise shipping data, including billable weights, can facilitate negotiations for more favorable rates.

Conclusion: Why Accurate and Simplified Billing is Crucial for Businesses

Accurate and streamlined billing is vital for businesses to manage shipping costs effectively and ensure timely, safe, and cost-efficient delivery of goods. By comprehensively understanding billable weight, meticulously calculating and tracking it, and adopting best practices to reduce it, businesses can simplify their billing processes and achieve significant savings on shipping expenses.