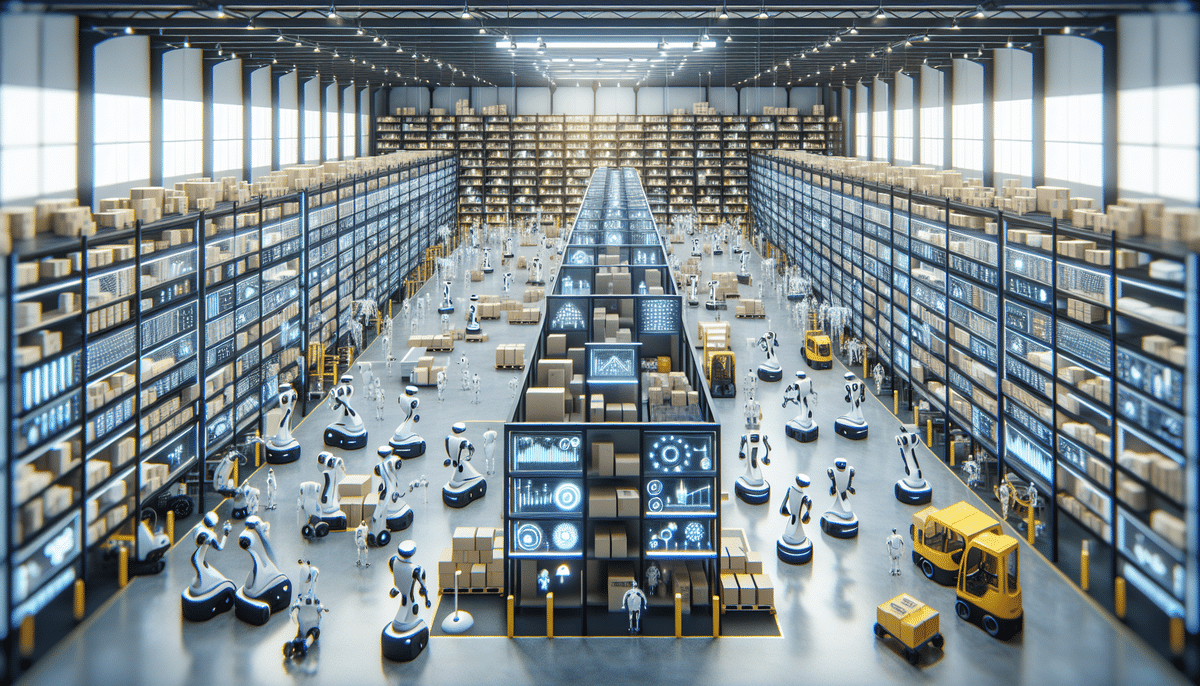

Introduction to Smart Warehousing

The global warehousing industry has evolved considerably in recent years, propelled by the rise of e-commerce, automation, and innovation. One of the key trends shaping the industry today is smart warehousing. By integrating cutting-edge technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI), smart warehouses are revolutionizing the way businesses manage their logistics and supply chain operations. According to a recent report by MarketsandMarkets, the smart warehousing market is projected to grow by $25.4 billion by 2026, with a CAGR of 14.0%.

Benefits of Smart Warehousing

Increased Efficiency

Implementing smart warehousing in your business offers numerous advantages. One of the most significant benefits is increased efficiency. By automating many of the manual tasks involved in warehouse operations, smart warehouses can significantly reduce the time and cost associated with managing inventory, including tasks such as picking, packing, shipping, and receiving.

Improved Inventory Accuracy

Another key advantage is improved inventory accuracy. Utilizing advanced sensors and tracking technologies allows businesses to gain real-time visibility into their inventory levels, thereby avoiding costly mistakes like stockouts or overstocks. This leads to better customer satisfaction, enhanced decision-making, and reduced waste.

Flexibility and Scalability

In addition to efficiency and accuracy, smart warehousing also offers increased flexibility and scalability. Traditional warehouses are often constrained by physical space and resources, whereas smart warehouses can easily scale operations up or down based on demand and adapt to changing business needs. This makes them an ideal solution for businesses aiming to grow and expand their operations.

Key Technologies in Smart Warehousing

The Role of IoT

The Internet of Things (IoT) is a pivotal technology driving the growth of smart warehousing. In smart warehouses, IoT devices are employed to track inventory, monitor machinery and equipment, and collect data on warehouse operations. This data is subsequently analyzed by AI and machine learning systems to optimize warehouse activities.

IoT sensors play a crucial role in tracking inventory levels and preventing stockouts. They monitor the movement of goods and their locations within the warehouse, providing businesses with real-time visibility into their inventory levels and enabling informed decisions regarding stock reordering.

Beyond inventory tracking, IoT devices also monitor machines and equipment within the warehouse, assessing machine performance and detecting potential issues before they escalate. Early detection of issues helps prevent downtime and reduce maintenance costs.

Enhancing Efficiency with AI

Artificial Intelligence (AI) is another fundamental technology in smart warehousing. AI systems analyze data collected by IoT devices to make informed decisions that optimize warehouse operations, including predicting demand patterns and optimizing routes for workers and machinery.

A key benefit of incorporating AI in smart warehousing is improved efficiency. AI systems analyze data in real-time, enabling the optimization of warehouse operations to reduce waste and increase throughput. This includes optimizing inventory levels and automating various warehouse processes.

Additionally, AI enhances accuracy by processing large volumes of data swiftly and precisely, allowing businesses to make informed decisions about inventory levels, shipping schedules, and other critical factors influencing warehouse operations.

Successful Implementations

Numerous companies have embraced smart warehousing, realizing benefits such as increased efficiency, accuracy, and scalability. For instance, Amazon has heavily invested in automation and robotics to enhance their warehouse operations. Amazon's fulfillment centers employ a network of robots and AI systems to streamline processes and expedite delivery times.

DHL has developed its own smart warehouse solution named SmartSensor. This AI-powered solution utilizes sensors and IoT devices to track asset locations and conditions in real-time, allowing for the optimization of warehouse operations and reduction in asset damage or loss risks.

Similarly, Walmart has been advancing towards smart warehousing by leveraging technologies like AI and robotics in their warehouses. These innovations have enabled Walmart to reduce costs, enhance efficiency, and maintain competitiveness in the dynamic retail sector.

Challenges and Solutions

Cost of Implementation

Despite the clear benefits, implementing and maintaining a smart warehouse system comes with challenges. One major challenge is the cost associated with these systems. Smart warehousing requires significant investments in hardware, software, and infrastructure, potentially posing a barrier to entry for smaller businesses.

Technical Integration

Technical challenges also arise from integrating various systems and technologies. Smart warehouses depend on a complex network of connected devices and systems, which can be difficult to manage and maintain, necessitating specialized training and expertise in areas like IoT, AI, and software development.

Security Concerns

Furthermore, there are security concerns linked to smart warehousing. The increased use of connected devices and networks heightens the risk of cyberattacks and data breaches, compelling businesses to invest in robust security measures to safeguard against such threats.

Market Trends and Future Outlook

Key Trends Driving Growth

The smart warehousing market is poised for rapid growth in the coming years, driven by several key trends:

- The surge in e-commerce and online shopping, leading to increased demand for efficient warehousing and logistics solutions.

- The imperative for improved efficiency and cost savings within the supply chain.

- The advancement of IoT and AI technologies, making smart warehousing more accessible and cost-effective.

- The rising adoption of cloud computing, facilitating easier access to and analysis of large data sets in real-time.

Impact of COVID-19

The COVID-19 pandemic significantly impacted the global economy and, in particular, the logistics industry. With many countries imposing lockdowns and social distancing measures, there was a surge in online shopping, resulting in increased demand for smart warehousing solutions.

Businesses that had already invested in smart warehousing before the pandemic were better equipped to handle the sudden increase in demand. They could swiftly adapt to new safety protocols and implement contactless delivery solutions, reducing infection risks and maintaining smooth operations.

The pandemic underscored the importance of flexibility and scalability in the supply chain. Smart warehousing solutions proved more adaptable and agile than traditional warehouses, making them an ideal choice for businesses navigating the challenges brought about by the pandemic.

Investment Opportunities

The expansion of the smart warehousing market presents numerous investment opportunities for businesses and investors alike. Opportunities exist in areas such as hardware, software, and infrastructure. As the market continues to develop, businesses offering innovative solutions and services are well-positioned to capture significant market share.

Success in the smart warehousing market hinges on identifying areas ripe for innovation and developing solutions that address these needs. This requires a deep understanding of the market dynamics and an ability to stay ahead of emerging trends and technologies.

Future Outlook

The future of the smart warehousing industry appears promising. With the growing demand for efficient and scalable logistics solutions, smart warehouses are set to become the standard rather than the exception in the coming years. Advances in IoT and AI technologies continue to make smart warehousing more accessible and cost-effective, positioning businesses that embrace these technologies for success.

However, challenges remain, such as the high costs and complexity associated with implementing these systems. As the industry evolves, new solutions and technologies are likely to emerge, addressing these challenges and further enhancing the accessibility and effectiveness of smart warehousing.

Implementation Guide

Choosing the Right Smart Warehouse Solution

Selecting the right smart warehouse solution for your business can be a complex task, given the multitude of vendors and solutions available, each with their own strengths and weaknesses. To make an informed decision, consider factors such as your business needs, budget, and objectives.

Key considerations include the desired level of automation and customization required for your business. Some solutions may be better suited for businesses needing high levels of automation, while others may cater to businesses with unique requirements or workflows. Additionally, consider the level of support and training provided with each solution, as well as the upfront and ongoing costs associated with implementation and maintenance.

Best Practices for Implementation

Implementing a smart warehouse system demands thorough planning and execution. To ensure a successful implementation, businesses should adhere to best practices such as:

- Developing a clear roadmap and timeline for the implementation process.

- Securing buy-in and support from key stakeholders, including management and staff.

- Investing in robust security measures to protect against cyber threats and data breaches.

- Providing comprehensive training and support to staff members.

- Monitoring and analyzing data to identify areas for improvement and optimization.

Traditional vs. Smart Warehousing: Pros and Cons

When assessing the benefits of smart warehousing, it is essential to compare it with traditional warehousing solutions. While traditional warehousing has been the standard for many years, it has several limitations that make it less efficient and scalable compared to smart warehousing.

Pros of Traditional Warehousing

- Lower initial investment and maintenance costs.

- Greater control over warehouse processes and workflows.

- Availability of a skilled labor force for manual tasks such as picking and packing.

Cons of Traditional Warehousing

- Limited scalability and flexibility.

- Higher error rates and lower inventory accuracy.

- Higher labor costs and slower processing times.

Advantages of Smart Warehousing

- Increased efficiency and scalability.

- Better inventory accuracy and reduced error rates.

- Lower labor costs and faster processing times.

However, smart warehousing solutions also have drawbacks, including:

- Higher initial investment and maintenance costs.

- Greater reliance on technology and automation, which can be a barrier for some businesses.

- Increased risk of cyber threats and data breaches.

Conclusion

The smart warehousing market is anticipated to grow rapidly in the coming years, fueled by the escalating demand for efficient and scalable logistics solutions. Despite the challenges associated with implementing and maintaining smart warehouse systems, the benefits are evident. Businesses that adopt emerging technologies like IoT and AI will be well-positioned to thrive and secure a significant market share in the foreseeable future.