Strategies for Optimizing Inventory Placement

Effective inventory placement is a cornerstone of a successful e-commerce business. It not only influences your operational efficiency and profitability but also significantly impacts customer satisfaction. This article delves into the importance of inventory placement, methods to determine optimal placement, and best practices to enhance your inventory strategy.

The Importance of Inventory Placement in E-commerce

Inventory placement involves strategically storing products within your warehouse to maximize efficiency and profitability. Proper placement minimizes fulfillment time and costs, while improper organization can lead to increased handling time, higher shipping expenses, and potential product damage or loss.

According to a Logistics Management report, optimized warehouse layout can improve order fulfillment speed by up to 25%. High-demand items should be stored near shipping areas to expedite processing, enhancing customer satisfaction and encouraging repeat business.

Additionally, considering the size and weight of products is essential. Heavier items are best placed on lower shelves or closer to the ground to facilitate easier handling and reduce the risk of injury or product damage.

Determining the Best Placement for Your Inventory

Analyzing Sales Data

Start by examining your sales history to identify top-selling and slow-moving items. High-demand products should occupy easily accessible locations, while slower-moving items can be stored in less prominent areas to optimize space utilization.

Considering Product Characteristics

Fragile items need to be stored in areas protected from potential damage, while bulky or heavy items should be placed at waist height for ease of access and handling.

Seasonal Inventory Management

Seasonal products, such as holiday decorations or seasonal apparel, require strategic placement to ensure they are readily available during peak seasons. Employing a flexible storage system can help accommodate seasonal fluctuations efficiently.

Using Data and Analytics to Optimize Inventory Placement

A data-driven approach is paramount in optimizing inventory placement. By leveraging data from your e-commerce platform, inventory management systems, and sales history, you can identify trends and make informed decisions about product storage locations.

For example, analyzing customer location data can enable you to position inventory closer to key markets, reducing shipping times and costs. According to a study by Supply Chain Digital, data analytics can enhance inventory accuracy by up to 50%, leading to better inventory management and customer satisfaction.

Furthermore, understanding seasonal trends and product popularity helps ensure that inventory placement aligns with market demand, preventing stockouts and overstock situations.

Benefits of Proper Inventory Placement on Customer Satisfaction

Efficient inventory placement leads to faster and more accurate order fulfillment, directly enhancing the customer experience. When customers receive their orders promptly and accurately, it fosters trust and encourages repeat business.

Moreover, organized inventory reduces the likelihood of damaged or lost products, ensuring that customers receive items in excellent condition. This reliability can differentiate your brand in a competitive market.

Effective inventory placement also supports better stock management, ensuring that popular items are consistently available, thereby increasing overall sales and customer loyalty.

Common Mistakes to Avoid in Inventory Placement

Overstocking Specific Areas

Overconcentration of inventory in particular locations can lead to congestion, making it challenging to access products and potentially slowing down operations.

Neglecting to Adapt to Demand Changes

Failing to adjust inventory placement based on changing demand trends can result in inefficiencies and lost sales opportunities.

Poor Labeling and Organization

Inadequate labeling and disorganization can cause confusion and delays in locating products, hampering order fulfillment processes.

Lack of Contingency Planning

Not having backup plans for unexpected inventory surges or shortages can disrupt operations and impact customer satisfaction.

Best Practices for Storing High-Demand Items

High-demand items should be placed in easily accessible locations near shipping areas to facilitate quick picking and packing. Implementing automated storage and retrieval systems (AS/RS) can further expedite these processes.

Regularly monitoring inventory levels ensures that popular products are always in stock. Additionally, considering the fragility and environmental needs of high-demand items, such as temperature control for perishables, helps maintain product quality and customer satisfaction.

Managing Seasonal Inventory Placement

Handling seasonal inventory requires flexibility and strategic planning. Leasing temporary warehouse space during peak seasons can accommodate excess inventory without disrupting regular operations.

Implementing a just-in-time (JIT) inventory system minimizes storage costs by ordering inventory only as needed. Additionally, positioning seasonal inventory closer to target markets can reduce shipping times and costs, enhancing customer satisfaction during high-demand periods.

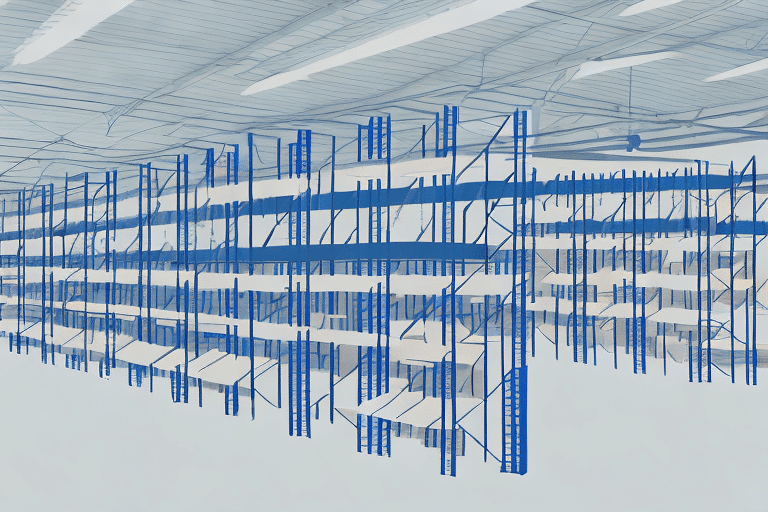

The Impact of Warehouse Layout on Inventory Placement

A well-organized warehouse layout is fundamental to efficient inventory placement. Utilizing pallet racking, conveyor systems, and clear labeling can streamline product movement and reduce the risk of damage or loss.

Optimizing the physical layout to align with product categories and demand patterns ensures that inventory placement supports operational efficiency and scalability.

Balancing Efficiency and Cost-Effectiveness in Inventory Placement

Achieving a balance between efficiency and cost-effectiveness involves evaluating the return on investment for various placement strategies. Conducting a cost-benefit analysis helps determine the most economically viable options.

Outsourcing fulfillment services to third-party logistics providers (3PLs) can also reduce costs and improve operational efficiency, allowing businesses to focus on core competencies while leveraging specialized expertise.

Optimizing Cross-Docking Processes

Cross-docking involves transferring products directly from incoming to outgoing shipments without long-term storage. This method can significantly streamline operations and reduce handling times.

Implementing automated systems, standardizing packaging, and training staff in efficient cross-docking procedures enhance the effectiveness of this strategy, leading to quicker order fulfillment and reduced operational costs.

The Relationship Between Order Fulfillment Time and Inventory Placement

Reducing order fulfillment time is critical for maintaining customer satisfaction and competitive advantage. Strategic inventory placement minimizes the time required for picking and packing, leading to faster delivery times.

Studies have shown that faster fulfillment times correlate with higher customer satisfaction rates and increased likelihood of repeat purchases.

Leveraging Automation to Enhance Inventory Placement

Automation technologies, such as automated storage and retrieval systems (AS/RS), conveyor systems, and barcode scanning, can dramatically improve the accuracy and efficiency of inventory placement.

Real-time inventory management enabled by automation allows for dynamic adjustments to placement strategies, ensuring that operations remain responsive to changing demand patterns.

Measuring Success: Key Performance Indicators for Inventory Placement

Evaluating the effectiveness of your inventory placement strategy involves tracking key performance indicators (KPIs) such as order fulfillment time, inventory turnover rate, and sales velocity.

Regular monitoring and analysis of these KPIs provide insights into operational performance, highlighting areas for improvement and enabling data-driven decision-making.

Managing Excess or Slow-Moving Inventory

Proper placement of excess or slow-moving inventory can free up space for high-demand products. Storing these items in less accessible areas or leveraging vertical space can optimize warehouse capacity.

Offering discounts, promotions, or bundling slow-moving items can encourage sales, while donating excess inventory can mitigate losses and support corporate social responsibility initiatives.

Continual assessment and adjustment of inventory placement ensure that all products are managed efficiently, aligning with overall business objectives and market demands.

Optimizing inventory placement is an ongoing process that requires a comprehensive understanding of your products, operations, and customer behaviors. By adopting a data-driven approach, regularly reviewing your strategies, and implementing best practices, you can enhance operational efficiency, reduce costs, and elevate customer satisfaction.