The Benefits of Automated Palletization

In today's fast-paced industrial landscape, automation has become a cornerstone of manufacturing and warehousing operations. One significant area where automation has revolutionized efficiency and productivity is palletization. Automated palletization offers numerous advantages, including time savings, reduced labor costs, and enhanced safety. In this article, we delve into the benefits of automated palletization, explore its workings, trace its historical evolution, and discuss future advancements in this dynamic field.

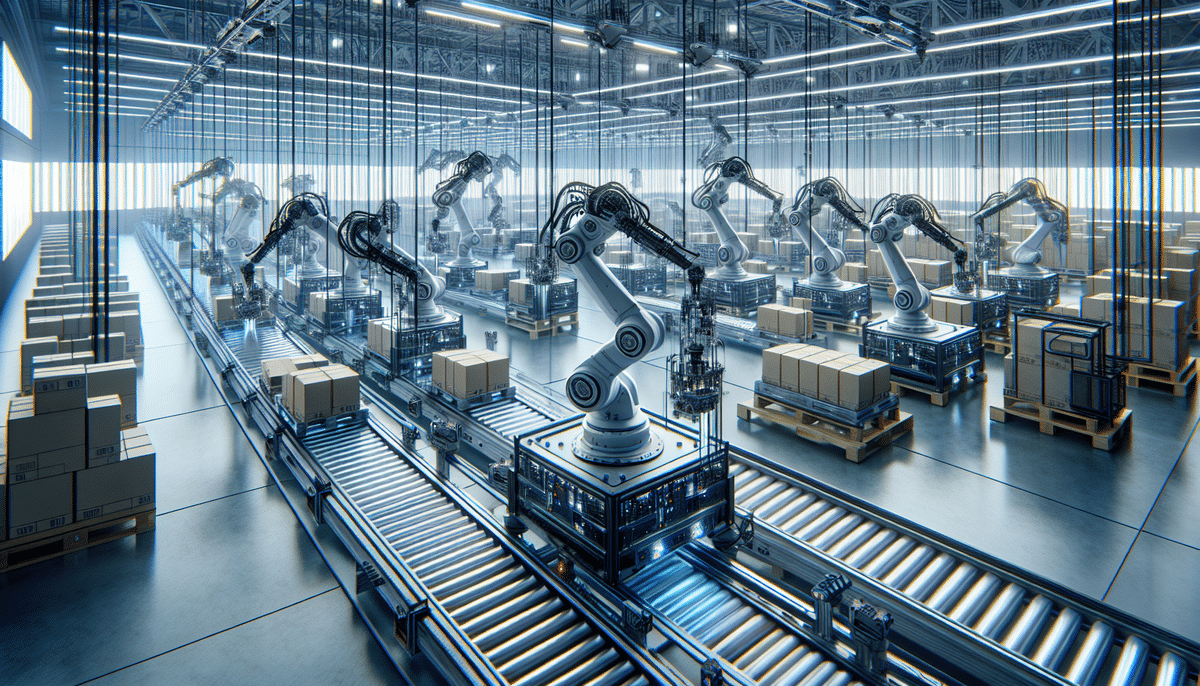

What is Automated Palletization and How Does it Work?

Automated palletization involves the use of robots and conveyor systems to efficiently stack and organize products on pallets. In an automated setup, products are placed onto a conveyor system and transported to a palletizing robot, which arranges them into predetermined patterns on a pallet. The pallet is then secured and wrapped, making it ready for shipment. These systems can be customized to handle a diverse range of products and pallet sizes, offering a versatile solution for materials handling.

One of the primary benefits of automated palletization is increased efficiency and productivity. By delegating the palletizing process to robots, businesses can minimize the need for manual labor, thereby reducing the risk of workplace injuries and boosting overall output. Automated systems can operate continuously, 24/7, enabling uninterrupted production and quicker turnaround times. According to a McKinsey report, automation can increase warehouse productivity by up to 30%, leading to significant cost savings and enhanced customer satisfaction through faster delivery.

The History of Palletization and Its Evolution into Automation

The concept of palletization emerged in the 1920s with the introduction of wooden pallets for transporting goods. Over the decades, pallets have become integral to logistics, with materials like plastic and metal enhancing durability and flexibility. The journey toward automation in palletization began in the 1950s with the advent of mechanical machines designed to stack boxes onto pallets. Since then, technological advancements have transformed palletization, integrating sophisticated robots and software that handle complex operations with precision. Today, automation has made palletization a highly efficient and accurate process.

One significant advantage of automated palletization is the reduction of human error. Advanced software and robotics ensure that palletization is more accurate and consistent, decreasing the likelihood of damaged goods during transportation and minimizing the reliance on manual labor. Additionally, automated systems facilitate faster processing times, enhancing productivity and reducing operational costs. As technology continues to progress, the palletization process is expected to become even more efficient and cost-effective.

The Advantages of Automating Your Palletization Process

Automating your palletization process brings a multitude of benefits, including:

- Increased Efficiency

- Improved Safety

- Enhanced Productivity

- Better Inventory Management

- Reduced Labor Costs

- Improved Quality Control

- Reduced Environmental Impact

Increased Efficiency: How Automation Can Save You Time and Money

Automated palletization significantly reduces the time and effort required for manual labor, leading to enhanced productivity and output. Robots can operate continuously without breaks, allowing for faster palletizing of products compared to manual methods. This increased efficiency results in substantial cost savings, as businesses can achieve higher throughput with fewer labor hours. According to Forbes, businesses can save up to 20% in operational costs by implementing automated systems.

Improved Safety: Eliminating the Risks of Manual Palletization

Manual palletization involves repetitive motions and heavy lifting, which can lead to employee fatigue and a higher risk of injuries. Automated palletization mitigates these risks by removing the need for employees to perform physically demanding tasks. This not only enhances workplace safety but also reduces the incidence of workers' compensation claims and related costs. According to the Occupational Safety and Health Administration (OSHA), automation can decrease workplace injuries by up to 40%.

Enhanced Productivity: How Automation Can Boost Your Output

Automated palletization systems can handle larger volumes of products more efficiently than manual methods, leading to increased productivity. Robots can operate around the clock, enabling businesses to meet high-demand periods without the need for additional labor. This scalability ensures that businesses can manage seasonal spikes and reduce backlogs effectively. Enhanced productivity through automation can lead to higher revenues and improved market competitiveness.

Better Inventory Management: How Automated Palletization Can Improve Tracking and Control

With automated palletization, businesses gain enhanced inventory tracking and control. Automated systems can accurately record the location and quantity of each item on a pallet, facilitating real-time inventory management. This precision helps in minimizing stockouts and overstock situations, leading to better resource allocation and reduced holding costs. Integrating palletization systems with Warehouse Management Systems (WMS) can further streamline inventory processes, as highlighted by Supply Chain Digital.

Reduced Labor Costs: The Financial Benefits of Automating Palletization

Automated palletization can lead to significant labor cost savings. By reducing the need for manual labor, businesses can allocate resources more efficiently and lower their overall wage expenses. Additionally, the increased productivity and efficiency of automated systems contribute to higher profitability and revenue growth. According to a study by Bureau of Labor Statistics (BLS), automation can reduce labor costs by up to 25% in warehousing operations.

Improved Quality Control: How Automation Can Ensure Consistency and Accuracy

Automated palletization ensures consistency and accuracy in the palletizing process. Robots can be programmed to follow precise patterns and configurations, ensuring uniformity across all pallets. This consistency helps maintain high-quality standards, reducing the likelihood of product damage during transportation and enhancing customer satisfaction. Automated quality control systems can also perform real-time inspections, identifying and addressing issues promptly.

Reduced Environmental Impact: How Automation Can Help Businesses Go Green

Automated palletization contributes to environmental sustainability by optimizing resource usage and reducing waste. Efficient palletizing reduces the amount of energy and materials required to handle the same workload, lowering the overall carbon footprint. Additionally, automated systems can enhance recycling efforts by accurately sorting and managing materials, supporting businesses in achieving their sustainability goals.

Choosing the Right Automated Palletization System for Your Business

Selecting the appropriate automated palletization system involves considering several factors, including the types of products being palletized, speed and output requirements, and the types of pallets used. Collaborating with a reputable vendor, such as ShipScience, can help businesses identify the best system tailored to their specific needs. Key considerations include:

- Customization: Evaluate whether the system can handle unique product shapes or sizes and accommodate multiple pallet configurations.

- Maintenance: Choose a system that is easy to maintain and has readily available replacement parts to minimize downtime.

- Scalability: Ensure the system can scale with your business growth and adapt to changing production demands.

- Integration: Consider how well the palletization system integrates with existing Warehouse Management Systems (WMS) and other technologies.

By addressing these factors, businesses can achieve substantial cost savings, increased efficiency, and improved safety for their employees.

Case Studies: Real-World Examples of Successful Automated Palletization Implementation

Numerous businesses have successfully implemented automated palletization systems, resulting in increased efficiency and cost savings. Here are a few examples:

Large Food Manufacturer

A leading food manufacturer automated its palletization process, leading to an 80% reduction in manual labor. This transition not only resulted in significant cost savings but also boosted productivity by 35%, allowing the company to meet growing demand without compromising quality.

Consumer Goods Manufacturer

A major consumer goods company integrated a robotic palletization system, effectively doubling its output capacity without the need for additional manual labor. This implementation streamlined operations, reduced lead times, and enhanced the company's ability to scale production during peak seasons.

Logistics Company

A logistics firm adopted an automated palletization system capable of handling various pallet sizes and weights. This flexibility optimized warehouse space utilization and minimized the need for manual intervention. As a result, the company increased its throughput by 25% and significantly reduced operating costs.

Pharmaceutical Company

A pharmaceutical company implemented an automated palletization system designed to handle delicate and sensitive products. This system ensured meticulous handling, reducing the risk of product damage during palletization. Consequently, the company improved product quality and minimized losses from damaged goods, leading to substantial cost savings.

Future Developments in Automated Palletization Technology

The future of automated palletization promises continued advancements that will further enhance efficiency and effectiveness. Key areas of development include:

- Intelligent Systems: The development of intelligent palletization systems that can automatically adapt to different environments and product types, increasing versatility and reducing setup times.

- Artificial Intelligence and Machine Learning: Integration of AI and machine learning to improve the precision and decision-making capabilities of palletization robots, leading to increased efficiency and reduced labor costs.

- IoT Integration: Incorporating sensors and Internet of Things (IoT) devices to provide real-time data on the palletization process, including product weight, dimensions, and pallet movement. This data enables optimization of the process, error reduction, and remote monitoring capabilities.

- Enhanced Connectivity: Improved connectivity with other automated systems and enterprise resource planning (ERP) software to create seamless and fully integrated warehouse operations.

These advancements are expected to drive further efficiencies, reduce operational costs, and enhance the overall effectiveness of automated palletization systems.

Common Misconceptions About Automated Palletization

Apart from the evident benefits, several misconceptions may deter businesses from adopting automated palletization:

- High Cost: Many believe that automated palletization systems are prohibitively expensive. However, the return on investment (ROI) from increased efficiency and reduced labor costs often results in quick payback periods.

- Loss of Jobs: Another misconception is that automation completely replaces human workers. In reality, automated systems often require human oversight and maintenance, allowing employees to focus on more strategic tasks.

- Only for Large Enterprises: While automated palletization is popular among large-scale operations, there are solutions tailored for small and medium-sized businesses, offering scalability and customization to meet varied needs.

Addressing these misconceptions can help businesses make informed decisions about integrating automated palletization into their operations.

Top Considerations for Implementing Automated Palletization in Your Warehouse

When planning to implement an automated palletization system, consider the following key factors:

- Product Types: Assess the variety and specifications of products to ensure the system can handle different shapes, sizes, and weights.

- Warehouse Layout: Evaluate the size and layout of your warehouse to determine the optimal placement of palletizing equipment and conveyor systems.

- Pallet Types: Consider the types of pallets used in your operations and ensure compatibility with the automated system.

- Automation Level: Decide on the desired level of automation, from basic palletizing to fully integrated systems with real-time monitoring and AI capabilities.

- Vendor Support: Choose a vendor that offers comprehensive support, including installation, training, and ongoing maintenance services.

By carefully considering these factors, businesses can ensure a smooth implementation process and maximize the benefits of automated palletization.

Expert Tips for Maximizing the Benefits of Automated Palletization

To fully leverage the advantages of automated palletization, businesses should:

- Optimize Warehouse Layout: Design the warehouse layout to enhance the flow of goods and minimize transit times between different stages of the palletization process.

- Integrate Advanced Software: Utilize sophisticated software systems to track inventory in real-time, manage workflows, and analyze performance metrics.

- Provide Ongoing Training: Ensure that employees are well-trained in operating and maintaining the automated systems, fostering a culture of continuous improvement.

- Regular Performance Assessments: Continuously monitor the performance of the automated palletization system and make necessary adjustments to maintain optimal efficiency and productivity.

- Collaborate with Vendors: Work closely with vendors to stay updated on the latest technological advancements and implement upgrades that enhance system capabilities.

Implementing these strategies can help businesses maximize the return on their investment in automated palletization and achieve sustained operational excellence.

Conclusion

Automated palletization stands out as a transformative solution for businesses aiming to enhance efficiency, reduce labor costs, and improve safety in their materials handling processes. Despite the array of factors to consider during implementation, the benefits are substantial: increased productivity, superior inventory management, and significant cost reductions. By partnering with a reputable vendor like ShipScience and optimizing operational processes, businesses can harness the full potential of automated palletization, ensuring long-term advantages and competitive edge in the market.