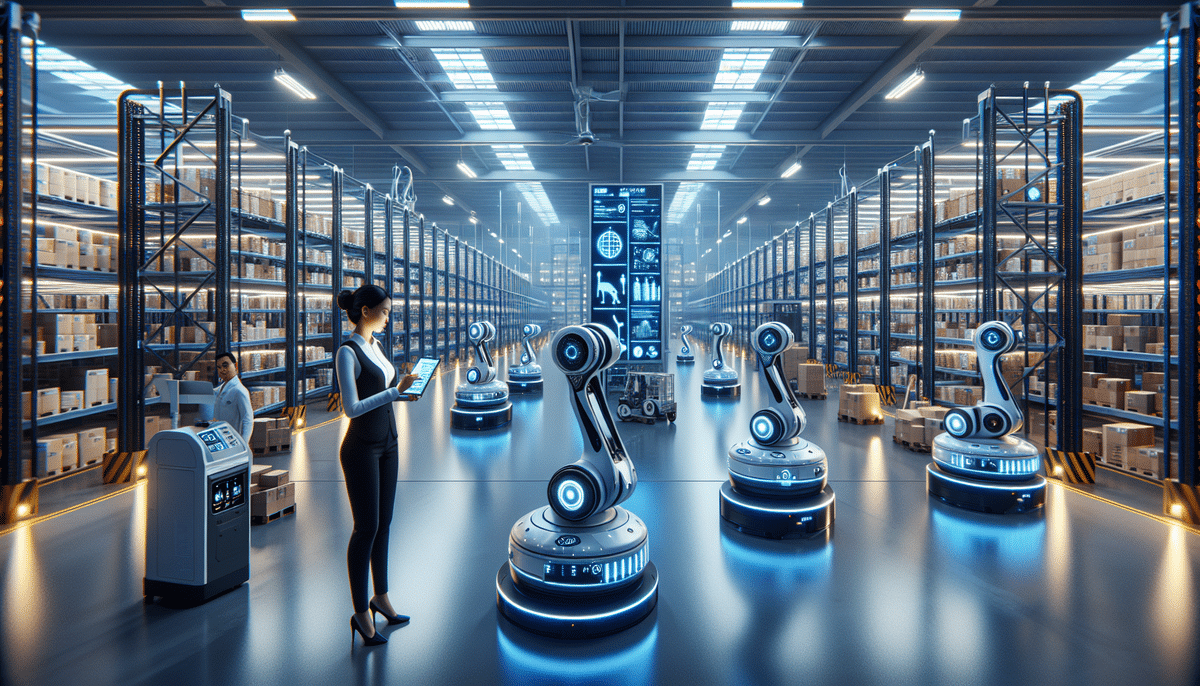

Introduction to Automated Putaway Solutions

Automated putaway solutions are increasingly becoming essential components of modern warehouse operations. As automation continues to transform various industries, warehouses of all sizes are adopting these advanced systems to enhance efficiency, accuracy, and overall productivity. Implementing automated putaway systems can revolutionize warehouse management by optimizing space utilization, improving inventory accuracy, and streamlining operations. This article explores the benefits of automated putaway solutions, their key features, cost savings, comparisons with manual processes, factors to consider when selecting a system, and real-life success stories.

Benefits and Advantages of Automated Putaway Systems

Improved Inventory Accuracy

Automated putaway systems significantly enhance inventory accuracy by tracking goods in real-time. This reduces the chances of misplaced or lost items, ensuring that inventory data is always up-to-date. According to a Gartner report, warehouses utilizing automated putaway systems experienced a 30% decrease in inventory discrepancies.

Optimized Space Utilization

Leveraging advanced algorithms and data analytics, automated putaway systems determine the most efficient storage locations for goods, minimizing wasted space. This optimization can lead to significant cost savings by maximizing storage capacity and reducing the need for additional warehouse space. A study by Logistics Management found that warehouses implementing automated putaway solutions saw up to a 25% increase in storage capacity.

Enhanced Order Fulfillment

Automated putaway solutions streamline the retrieval process, decreasing the time required to locate specific items. This improvement directly contributes to faster order fulfillment times and increased customer satisfaction. Faster order processing also reduces the likelihood of order inaccuracies and delays, fostering better customer relationships.

Cost Savings

Implementing automated putaway solutions can lead to substantial cost savings by reducing labor costs, minimizing errors, and optimizing operational workflows. Automated systems decrease the reliance on manual labor for storage and retrieval tasks, allowing warehouses to allocate resources more effectively and reduce overall operational expenses.

Key Features of Automated Putaway Solutions

- Real-Time Inventory Tracking: Continuously monitors inventory levels and locations, providing accurate and up-to-date information.

- Accurate Location Identification: Ensures goods are stored in predefined optimal locations based on size, demand, and other factors.

- Automated Goods Movement: Utilizes robotics and conveyor systems to transport and store items without manual intervention.

- Integration Capabilities: Seamlessly integrates with existing Warehouse Management Systems (WMS) and other technologies.

- Scalability: Designed to accommodate warehouse growth and increased inventory volumes effortlessly.

These features collectively enhance efficiency, reduce errors, and ensure the optimal use of warehouse space, making automated putaway systems indispensable for modern warehousing.

Cost Savings and Efficiency Gains

- Labor Reduction: Automation decreases the need for manual labor in storing and retrieving goods, leading to lower labor costs.

- Reduced Errors: Automated systems minimize human errors in inventory placement and tracking, reducing costs associated with misplaced or lost items.

- Increased Throughput: Faster and more accurate storage processes enhance overall warehouse throughput, allowing for higher order fulfillment rates.

- Lower Operational Costs: Optimized space utilization and efficient processes contribute to lower overall operational expenses.

For example, a DHL Supply Chain case study highlighted a 50% increase in productivity after implementing an automated putaway system, showcasing the tangible benefits of automation.

Comparing Manual and Automated Putaway Processes

- Manual Putaway: Suitable for small warehouses with limited inventory and a small workforce. It offers flexibility but is labor-intensive and prone to errors.

- Automated Putaway: Ideal for medium to large warehouses with high inventory turnover. Automation provides consistency, reduces errors, and enhances efficiency.

Advantages of Automated Putaway

- Increased accuracy through automated tracking and placement.

- Enhanced productivity by reducing time spent on manual storage tasks.

- Scalability to accommodate growing inventory levels.

Considerations

- Initial investment costs can be high for automated systems.

- Requires ongoing maintenance and updates to ensure optimal performance.

- May necessitate training for staff to effectively interact with automated systems.

Ultimately, warehouses with significant inventory and a need for high efficiency and accuracy will benefit more from automated putaway solutions, despite the higher initial costs.

Choosing the Right Automated Putaway Solution

Selecting the appropriate automated putaway system requires careful consideration of various factors to ensure it aligns with your warehouse's specific needs:

- Space Availability: Assess the available warehouse space to determine the type and size of the automated system that can be accommodated.

- Inventory Volume: Consider the volume and variety of inventory. High-volume warehouses may require more robust systems capable of handling large quantities efficiently.

- Customization: Ensure the system can be tailored to meet specific warehouse requirements, such as handling diverse product types or integrating with existing Warehouse Management Systems (WMS).

- Integration Capabilities: The solution should seamlessly integrate with your current technologies to facilitate smooth operations and data flow.

- Vendor Support and Training: Opt for vendors that offer comprehensive training and ongoing support to ensure effective system utilization and troubleshooting.

- Scalability: Choose a system that can scale with your business growth, accommodating increasing inventory levels without necessitating a complete overhaul.

By carefully evaluating these factors, warehouses can select an automated putaway solution that not only meets current operational demands but also supports future growth and efficiency goals.

Real-Life Success Stories

- Amazon: Known for its extensive use of automation, Amazon utilizes automated putaway systems to efficiently manage its vast inventory across multiple fulfillment centers. This automation has been pivotal in enabling Amazon to offer rapid delivery options, such as same-day and next-day shipping.

- Walmart: Walmart has incorporated automated putaway solutions to enhance inventory management and streamline its supply chain operations, resulting in improved stock accuracy and reduced labor costs.

- DHL Supply Chain: In a case study, DHL implemented an automated putaway system in their Netherlands warehouse, leading to a 50% increase in productivity. The system employs robots for the transportation and storage of goods, significantly reducing the reliance on manual labor.

- Shopify Fulfillment Network: Shopify has integrated automated putaway solutions to enhance the efficiency of its fulfillment centers, ensuring faster order processing and greater scalability to support the growing number of merchants using its platform.

These examples illustrate the transformative impact of automated putaway solutions, highlighting improvements in productivity, accuracy, and operational efficiency across various industries.

Conclusion

Automated putaway solutions have fundamentally transformed warehouse operations by enhancing productivity, reducing errors, and optimizing space utilization. Key features such as real-time inventory tracking, accurate location identification, and automated goods movement are essential for modern warehousing efficiency. When selecting an automated putaway system, it's crucial to consider factors like space availability, inventory volume, customization capabilities, and vendor support to ensure the solution aligns with your specific operational needs.

Moreover, automated putaway systems contribute to substantial cost savings by minimizing labor requirements, reducing inventory errors, and optimizing warehouse space. They also enhance inventory accuracy and traceability, ensuring reliable stock management and facilitating compliance with industry standards.

As the e-commerce landscape continues to evolve, the adoption of automated putaway solutions will remain a pivotal strategy for warehouses aiming to maintain competitiveness, meet increasing customer demands, and achieve sustainable operational success.