The Benefits of Implementing Warehouse Inventory Management

Efficient warehouse inventory management is crucial for businesses aiming to optimize their supply chain operations. By leveraging advanced inventory management systems, companies can achieve accurate tracking, streamline operations, reduce costs, and enhance customer satisfaction. This comprehensive guide explores the multifaceted benefits of implementing warehouse inventory management, addressing key challenges, advantages, and actionable strategies to get started.

Essential Role of Inventory Management in Business Growth

Foundation of a Robust Supply Chain

Inventory management serves as the backbone of any successful supply chain system. Accurate tracking and management prevent stockouts, overstocking, and inaccurate product tracking, which can lead to delayed fulfillment, lost sales, and dissatisfied customers. According to a Forbes report, businesses that implement effective inventory management systems experience a 20% increase in operational efficiency.

Optimizing Warehouse Space and Reducing Costs

Advanced inventory management systems analyze data to optimize warehouse layout and space utilization. By identifying high-turnover products, businesses can allocate space more effectively, reducing storage costs and minimizing waste. Studies show that optimized inventory management can lead to up to a 30% reduction in storage costs [1].

Enhancing Forecasting Accuracy

Accurate demand forecasting is pivotal for maintaining optimal inventory levels. By leveraging historical sales data and market trends, businesses can predict future product demand with greater precision. Improved forecasting helps avoid both stockouts and overstocking, ensuring that the right products are available when needed. According to a Supply Chain Digital study, data-driven forecasting can improve inventory accuracy by up to 50%.

Challenges Faced Without Effective Inventory Management

Inaccurate Inventory Tracking

Without a robust inventory management system, businesses often encounter discrepancies between actual stock levels and recorded data. This can result in order fulfillment delays, increased return rates, and loss of customer trust.

Stockouts and Overstocking

Inadequate inventory tracking leads to frequent stockouts and overstocking situations. Stockouts cause lost sales and harm customer relationships, while overstocking ties up capital and increases holding costs.

Poor Data Visibility

Lacking real-time inventory data restricts a company's ability to make informed decisions. Poor visibility can hinder strategic planning, delay response to market changes, and reduce overall operational efficiency.

Streamlining Operations with Inventory Management Systems

Real-Time Inventory Tracking

Modern inventory management systems offer real-time tracking capabilities, allowing businesses to monitor stock levels continuously. This enables timely restocking and reduces the risk of overstocking or stockouts.

Optimizing Warehouse Layout

By analyzing inventory data, companies can design efficient warehouse layouts that minimize travel time and streamline picking processes. This leads to faster order fulfillment and increased productivity.

Automating Workflows and Processes

Automation features such as barcode scanning and RFID tagging reduce human error and enhance data accuracy. Automated workflows ensure consistent and reliable order fulfillment, improving overall operational efficiency.

Real-World Success Stories

Amazon

Amazon's state-of-the-art inventory management system enables rapid order fulfillment, ensuring products reach customers within hours. Their investment in automation and data analytics has set industry standards for efficiency and customer satisfaction.

Walmart

Walmart has successfully reduced out-of-stock items by 16% through the implementation of advanced inventory management solutions, leading to increased sales and improved customer loyalty.

Samsung

Samsung centralized its supply chain management, resulting in millions saved in operational costs and enhanced coordination across global warehouses.

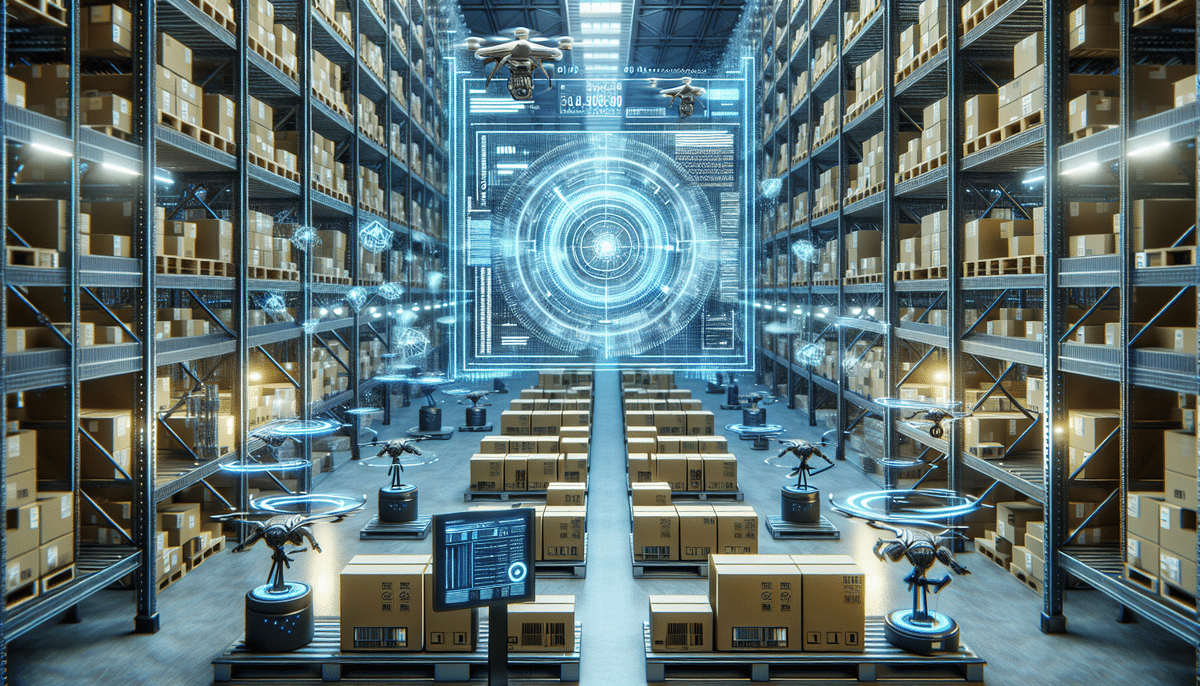

The Role of Technology in Modern Inventory Management

Advanced Tracking Technologies

Technologies like RFID tagging, IoT sensors, and barcode scanning provide precise real-time tracking of inventory. These tools enhance visibility and accuracy, enabling better decision-making and efficient inventory control.

Artificial Intelligence and Machine Learning

AI and machine learning algorithms analyze vast amounts of data to predict demand patterns, optimize stock levels, and identify trends. These technologies enhance forecasting accuracy and contribute to proactive inventory management.

Automation and Robotics

Automation in warehousing, including the use of robots for picking and packing, reduces labor costs and increases speed and accuracy in order processing. According to a Business Insider report, automation can increase warehouse productivity by up to 25%.

Best Practices for Implementing Inventory Management Systems

Conduct Comprehensive Inventory Audits

Before implementing a new system, perform thorough inventory audits to assess current stock levels and data accuracy. This step ensures a smooth transition and accurate data migration.

Plan for Data Migration

Develop a detailed plan for migrating data from existing systems to the new inventory management platform. Ensure data integrity and consistency to avoid discrepancies.

Integrate with Existing Software

Choose an inventory management system that seamlessly integrates with other business tools such as accounting software, ERP systems, and e-commerce platforms. Integration enhances data flow and operational cohesion.

Provide Comprehensive Employee Training

Equip your team with the necessary skills to utilize the new system effectively. Regular training sessions and ongoing support ensure that employees can leverage the system's full potential.

Establish Clear Procedures

Define and document standard operating procedures for inventory management, including roles, responsibilities, and workflows. Clear procedures maintain data accuracy and operational consistency.

Cost Savings and Return on Investment (ROI)

Reducing Operational Costs

Effective inventory management minimizes holding costs, reduces waste, and lowers labor expenses through automation. Businesses can experience significant cost savings, often recouping the investment within the first year.

Preventing Lost Sales

By avoiding stockouts, companies ensure that customers can always purchase desired products, leading to increased sales and customer retention.

Enhancing Fulfillment Efficiency

Improved inventory accuracy and optimized workflows accelerate order processing times, enhancing overall operational efficiency and customer satisfaction.

Choosing the Right Inventory Management System

Assessing Business Needs

Evaluate your company's specific requirements, including the scale of operations, budget constraints, and desired features. A tailored approach ensures that the chosen system aligns with your business objectives.

Evaluating System Features

Key features to consider include real-time tracking, integration capabilities, scalability, and user-friendliness. Prioritize functionalities that address your most pressing inventory challenges.

Considering Vendor Support and Training

Choose a vendor that offers comprehensive support, including training, troubleshooting, and regular updates. Reliable support ensures smooth system operation and continuous improvement.

Reading Reviews and Seeking Recommendations

Research different inventory management systems, read user reviews, and seek recommendations from industry peers. Informed decision-making leads to selecting a system that best fits your business needs.

Avoiding Common Implementation Mistakes

Skipping Inventory Audits

Failing to conduct thorough inventory audits before system implementation can result in inaccurate data and diminished system effectiveness.

Insufficient Training

Neglecting to provide adequate training to employees can lead to improper system usage, errors, and reduced efficiency. Ensure comprehensive training programs are in place.

Ignoring System Customization

Choosing a system that doesn't meet your specific business needs can hinder operations. Select a customizable solution that can adapt to your unique requirements.

Overlooking Maintenance and Updates

Regular system maintenance and updates are essential for optimal performance. Neglecting this can lead to data inaccuracies and operational inefficiencies.

Future Trends in Warehouse Inventory Management

Increased Automation and Robotics

The integration of robotics in warehouses will continue to grow, enhancing speed and accuracy in inventory handling and order fulfillment.

Artificial Intelligence and Predictive Analytics

AI-driven analytics will provide deeper insights into inventory trends, enabling more precise demand forecasting and proactive inventory management.

Internet of Things (IoT) Integration

IoT devices will offer enhanced real-time tracking and monitoring of inventory, improving data accuracy and operational transparency.

Augmented Reality (AR) Applications

AR technology will assist in employee training, warehouse layout optimization, and improving the efficiency of picking and packing processes.

Blockchain for Enhanced Transparency

Blockchain technology will introduce greater transparency and security in supply chain transactions, ensuring data integrity and reducing fraud.

Conclusion

Implementing a warehouse inventory management system is a strategic move that can transform your business operations. By enhancing accuracy, optimizing space, reducing costs, and improving customer satisfaction, effective inventory management drives business growth and profitability. Selecting the right system, adhering to best practices, and staying abreast of emerging trends will ensure sustained success in an increasingly competitive market.

For more insights on optimizing your supply chain and inventory management, refer to Supply Chain Digital and McKinsey Operations Insights.