The Benefits of Kitting in Manufacturing

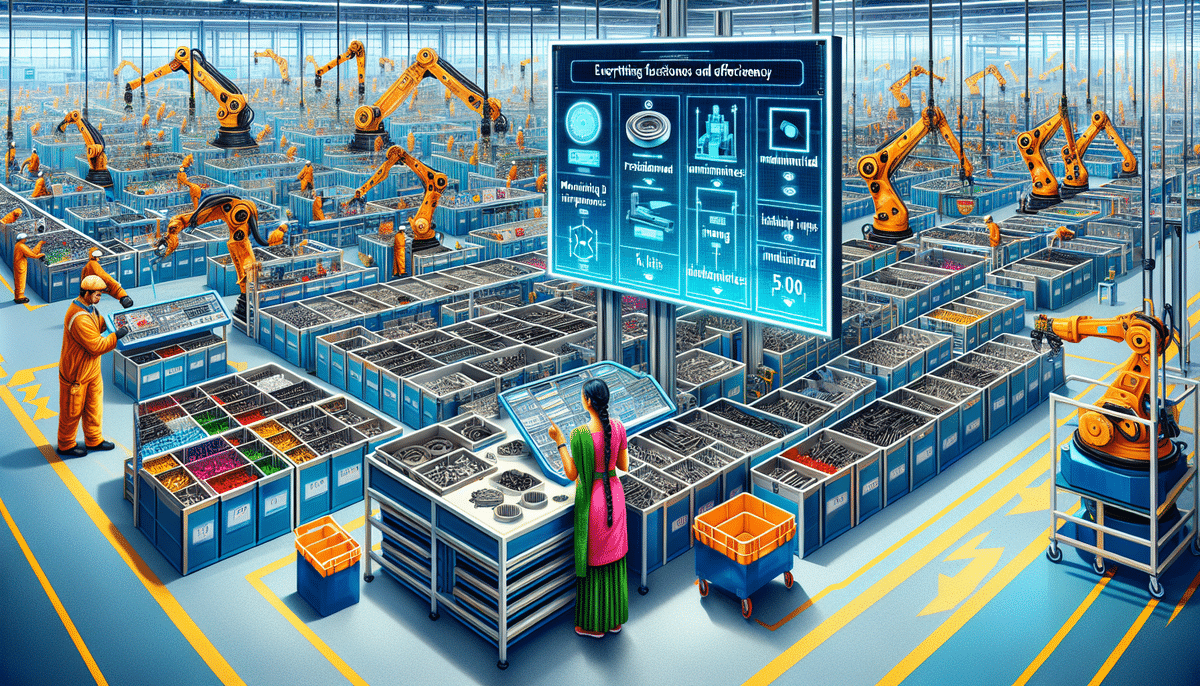

Manufacturers are continually seeking ways to streamline processes, reduce waste, and increase efficiency. One method that has gained significant traction in recent years is kitting. Kitting involves grouping all the components needed for a specific job into pre-measured and pre-packaged kits. This approach can greatly enhance production lines, offering numerous benefits that contribute to overall operational excellence.

How Kitting Can Streamline Your Manufacturing Process

The kitting process optimizes manufacturing by reducing material handling, search time, and setup time. Pre-packaged kits allow easy access to all necessary materials, minimizing the time spent locating specific parts. According to a 2023 Industry Report, companies implementing kitting have seen a 25% reduction in assembly times.

Another advantage of kitting is waste reduction. By packaging materials in exact quantities needed for each assembly, the likelihood of excess materials is minimized, leading to decreased waste. Enhanced inventory management is another benefit, as it allows for better tracking of materials and reduces the risk of overstocking or understocking.

Kitting also plays a crucial role in improving quality control. With all necessary materials in one kit, it's easier to verify that every component is present before assembly, preventing errors and defects in the final product. This leads to higher customer satisfaction and fewer returns or repairs.

The Advantages of Implementing a Kitting System in Your Facility

Implementing a kitting system offers significant advantages, including reduced inventory, labor, and administrative costs. By optimizing the quantity of each component needed, facilities can save space previously required for storing individual components separately. Additionally, kits make it easier to monitor inventory levels, minimizing production line downtime due to stock shortages.

Furthermore, kitting improves the accuracy and speed of the assembly process. Workers can quickly access and identify the parts they need, reducing errors and delays. This efficiency boost can lead to increased productivity and faster order turnaround times. Kitting systems are also highly customizable, allowing businesses to tailor them to their specific needs, thereby enhancing flexibility and adaptability in the manufacturing process.

Kitting vs. Traditional Manufacturing: Which is More Efficient?

When comparing kitting to traditional manufacturing methods, one of the standout benefits of kitting is the reduction in material handling. This leads to a more efficient assembly process and can result in higher output. Although kitting requires an initial increase in setup time to create the kits, the long-term gains in efficiency typically outweigh these initial costs.

Kitting also facilitates better inventory management by pre-packaging necessary components for each assembly, making it easier to track inventory levels and reorder supplies as needed. This proactive approach helps prevent stockouts and reduce the risk of production delays. Additionally, kitting enhances quality control by ensuring that the correct components are used in each assembly, lowering the likelihood of errors or defects.

How to Optimize Your Production Line with Kitting Strategies

Optimizing a production line with kitting strategies involves efficient kit packing, considering factors like anticipated demand, kit size, and component frequency. By doing so, manufacturers can minimize the number of kits required, reduce storage space, and maintain smooth production flow with minimal downtime.

Accuracy in kit contents is crucial. Ensuring that each kit includes the correct components is essential to prevent delays and errors in production. Implementing technologies such as barcode scanning or automated verification systems can help maintain accuracy. According to a study by McKinsey & Company, automated kitting systems can reduce error rates by up to 40%.

The Impact of Kitting on Inventory Management in Manufacturing

Kitting significantly enhances inventory management by consolidating all components required for a specific job into a single kit. This consolidation reduces the need to track individual components separately, leading to more accurate inventory counts. Additionally, having all necessary components in one kit simplifies the process of pulling materials from inventory, eliminating the need to search for individual parts.

Moreover, kitting streamlines the production process by providing workers with immediate access to all required components, resulting in faster production times and increased efficiency. It also contributes to waste reduction by ensuring that only the necessary components are used for each job, preventing excess parts from being left unused.

From Raw Materials to Finished Product: A Look at the Kitting Process

The kitting process starts with the delivery of raw materials to the manufacturing facility. These materials are then broken down into individual components, measured, and packaged in the required quantities. The components are organized into kits, labeled, and stored until they are needed for production. When a kit is requisitioned, it is collected and used in the production process.

This pre-packaging allows workers to quickly access necessary materials, reducing production times and boosting overall productivity. Additionally, precise measurement and packaging of components help minimize material waste, benefiting both the environment and operational costs.

Enhancing Quality Control with Effective Kitting Practices

Kitting enhances quality control by bundling all necessary components in pre-measured quantities, thereby reducing human error and ensuring consistency in each kit. This consistency leads to higher quality products and easier identification of any quality control issues that may arise.

Effective kitting practices streamline the production process, as workers have immediate access to all required components without the need to search for individual parts. This efficiency results in faster production times and increased output.

Additionally, kitting aids inventory management by simplifying the tracking of kits and components, preventing overstocking or understocking of parts, and ensuring smooth production runs.

Breaking Down the Costs: Why Kitting is a Cost-Effective Solution for Manufacturers

Kitting offers a cost-effective solution for manufacturers by reducing material handling, optimizing inventory, and minimizing the need for extensive storage space. It also lowers labor costs by decreasing the time spent searching for specific components. Although there is an initial setup time required to create the kits, the long-term benefits of kitting significantly outweigh these initial costs.

Enhanced production efficiency is another financial benefit of kitting. Workers can complete tasks more quickly and with fewer errors, leading to faster turnaround times and increased productivity. Kitting also improves supply chain management by reducing the risk of stockouts and ensuring that all necessary components are available when needed.

Moreover, kitting is valuable for managing product variations. By creating kits for different product configurations, manufacturers can streamline the production process and reduce the risk of errors. This is particularly beneficial for companies producing a wide range of products with varying components, as it ensures the correct components are used for each product, enhancing quality control.

Case Studies: Real-Life Examples of Successful Implementation of Kitting in Manufacturing

Various manufacturers have successfully implemented kitting in their processes, demonstrating its effectiveness. For instance, a medical device manufacturer reported a 30% increase in productivity and a 70% reduction in inventory after adopting a kitting system. Another manufacturer experienced a 50% reduction in setup times and a 20% decrease in production costs following the introduction of kitting.

The Future of Manufacturing: The Role of Kitting in Industry 4.0

Industry 4.0 represents the next phase of the manufacturing revolution, characterized by the integration of digital technologies to enhance manufacturing processes. Kitting is poised to play a significant role in this evolution by reducing waste and optimizing production processes. Future advancements may include the integration of machine learning and artificial intelligence to further enhance the efficiency and accuracy of kitting processes.

Tips for Choosing the Right Kitting Software for Your Manufacturing Business

Selecting the appropriate kitting software is crucial for the success of the kitting process. When choosing kitting software, manufacturers should consider factors such as facility size, number of employees, and anticipated production levels. Essential features to look for include robust inventory management, automated purchasing, and barcode scanning capabilities.

Additionally, manufacturers should evaluate the software's ability to integrate with existing systems and its scalability to accommodate future growth. According to Software Advice, the right kitting software can enhance overall operational efficiency and provide valuable insights through data analytics.

Common Mistakes to Avoid When Implementing a Kitting System

Implementing a kitting system requires careful planning to ensure its success. One common mistake is failing to account for the unique needs of the manufacturer, including production levels and employee skill sets. It's essential to tailor the kitting system to these specific requirements to avoid inefficiencies.

Another mistake is over-packing or under-packing kits. Over-packing can lead to excessive waste, while under-packing can result in production line downtime. Striking the right balance is crucial for maintaining efficiency and minimizing costs.

How to Train Your Employees on Using a Kitting System Effectively

Proper employee training is vital for the successful implementation of a kitting system. Training programs should cover best practices for packing kits, identifying inventory issues, and the importance of accurate kit labeling. Comprehensive training ensures that employees understand how to use the system effectively, reducing errors and improving overall efficiency.

Moreover, training should extend beyond the production line to include quality control, shipping, and inventory management. This holistic approach ensures that all aspects of the kitting process are handled correctly, contributing to the system's overall success.

Measuring Success: Key Metrics for Evaluating the Performance of Your Kitting System

Evaluating the success of a kitting system involves monitoring key metrics to identify areas for improvement. Important metrics include the number of kits produced, the number of components in each kit, production line downtime, and employee satisfaction. Regularly assessing these metrics helps ensure that the kitting system operates efficiently and effectively.

Additionally, it's crucial to regularly evaluate inventory counts to maintain accuracy and identify any discrepancies that may require further investigation. Continuous monitoring and analysis enable manufacturers to optimize their kitting processes, leading to sustained operational excellence.

Overall, the benefits of kitting in manufacturing are substantial. From streamlining the production process to enhancing quality control, kitting is a valuable solution that manufacturers should consider to improve efficiency and reduce costs.