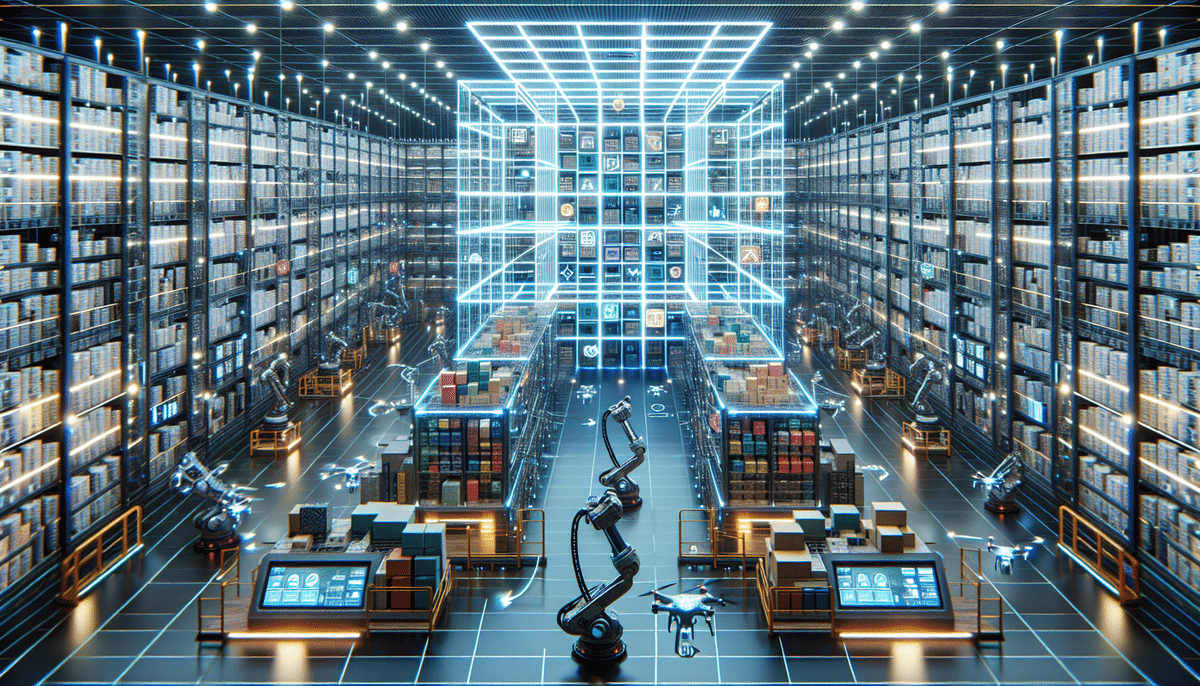

The Cubic Storage Model: The New Industry Standard

Are you tired of inefficient and error-prone warehouse management systems? Say hello to the Cubic Storage Model, the new industry standard that is revolutionizing warehouse operations. In this article, we will explore what the Cubic Storage Model is and how it works, its advantages, how to implement it in your warehouse, cost savings and efficiency gains, real-world case studies, and more.

What is the Cubic Storage Model and How Does it Work?

The Cubic Storage Model is a modern warehousing system that utilizes efficient storage techniques to maximize space utilization and increase productivity. Unlike traditional warehouse management systems, the Cubic Storage Model adopts a 3D approach, optimizing height in addition to width and depth. This allows businesses to store more products within the same footprint, enhance picking accuracy, and reduce errors.

The Cubic Storage Model works by dividing the warehouse into cubes or zones, each holding meticulously organized and labeled inventory for quick and easy retrieval. A sophisticated inventory management system, combined with intelligent automation, ensures that each product is stored and accessed with maximum efficiency. Leveraging advanced technologies such as robotics, sensors, and artificial intelligence, the system tracks inventory and streamlines the order fulfillment process.

One of the key benefits of the Cubic Storage Model is its adaptability to changing business needs. As companies grow and their inventory requirements evolve, the Cubic Storage Model can be reconfigured to accommodate new products and storage demands. This flexibility enables businesses to optimize their warehouse space and enhance efficiency over time without incurring costly renovations or expansions.

The Advantages of Using the Cubic Storage Model in Warehousing

The benefits of the Cubic Storage Model are numerous and far-reaching:

- Maximized space utilization: The 3D approach ensures that every inch of the warehouse is utilized, leading to optimal storage capacity and increased productivity.

- Reduced picking errors: The organization and labeling of products in each cube make it easier for workers to locate and retrieve items, resulting in fewer mistakes and increased accuracy.

- Increased operational efficiency: The automated system reduces manual labor and speeds up the order fulfillment process, enhancing overall efficiency.

- Cost savings: The Cubic Storage Model requires fewer resources to operate, such as less manual labor, reduced space rental, and lower energy costs, leading to significant cost savings for businesses.

- Real-time inventory tracking: The advanced inventory management system allows for real-time tracking of inventory levels and movement, providing accurate and up-to-date information to managers.

- Better ergonomics: The automated system reduces the likelihood of injuries and strains associated with manual labor, creating a safer and more comfortable work environment for employees.

Additionally, the Cubic Storage Model is highly scalable. As businesses grow and expand, the model can effortlessly accommodate increased storage needs without significant changes to the warehouse layout or system. This adaptability allows businesses to respond to changing market demands and maintain a competitive edge in their industry.

How to Implement the Cubic Storage Model in Your Warehouse

Implementing the Cubic Storage Model can be a significant transition for businesses, but with proper planning and execution, the process can be smooth and efficient. Here are the key steps to successfully adopt the Cubic Storage Model:

- Assess Current Inventory: Begin by evaluating your current inventory and identifying areas where the Cubic Storage Model can be applied effectively.

- Invest in Technology and Equipment: Acquire the necessary technology and equipment, such as robotics, sensors, and automation software. These tools are essential for managing inventory levels, tracking product movement, and accelerating the order fulfillment process.

- Employee Training: Train employees on the new system, including the operation of new technologies and equipment. Comprehensive training ensures that staff can manage the system efficiently.

- Monitor and Optimize: Continuously monitor the performance of the new system and make adjustments as needed. Regular evaluations of the inventory management process help identify areas for improvement and ensure optimal performance.

Implementing the Cubic Storage Model can significantly increase storage capacity by utilizing vertical space and optimizing the warehouse layout. This leads to cost savings and enhanced efficiency in the long run.

The Cost Savings and Efficiency Gains of the Cubic Storage Model

The Cubic Storage Model offers substantial cost savings and efficiency gains for businesses:

- Increased Capacity: The 3D approach allows for greater storage capacity within the same space, reducing the need to rent additional space or build new warehouses.

- Automation Benefits: Automating the order fulfillment process and inventory management decreases the reliance on manual labor, leading to fewer errors and higher productivity.

- Real-Time Tracking: Real-time inventory tracking and optimization enable businesses to make informed decisions, improve inventory management, and prevent stockouts or overstock situations, thereby reducing costs and enhancing efficiency.

- Improved Organization: Enhanced organization and accessibility of inventory facilitate quicker item retrieval, leading to faster order fulfillment and improved customer satisfaction.

- Environmental Impact: By maximizing space utilization, businesses can reduce their carbon footprint through decreased transportation and energy costs. Additionally, efficient inventory management minimizes waste by preventing overstocking and product expiration.

Case Studies: Real-World Examples of Successful Implementation of the Cubic Storage Model

Several businesses have successfully implemented the Cubic Storage Model, witnessing significant improvements in their warehousing operations:

- A multinational electronics retailer increased productivity by up to 400% after adopting the Cubic Storage Model. By optimizing inventory and reducing the need for manual labor, the retailer achieved substantial cost savings and enhanced efficiency.

- A large automotive parts manufacturer saw a 50% improvement in productivity by implementing the Cubic Storage Model. This led to reduced time and costs associated with order fulfillment and boosted customer satisfaction.

Overcoming Challenges Associated with Adopting the Cubic Storage Model

While the Cubic Storage Model offers numerous benefits, businesses may encounter certain challenges during adoption:

- Initial Costs: Implementing the Cubic Storage Model requires substantial investment in technology and equipment. Businesses must conduct a thorough cost-benefit analysis to ensure the investment is justified.

- Employee Training: Transitioning to a highly automated system necessitates comprehensive training for employees. Ensuring that staff are proficient in managing the new technologies is crucial for smooth operations.

- Operational Disruptions: The transition period may lead to temporary disruptions in operations. Proper planning and phased implementation can help mitigate these disruptions.

How the Cubic Storage Model is Revolutionizing Warehousing Operations

The Cubic Storage Model is transforming warehousing operations by offering a more efficient, accurate, and cost-effective method of managing inventory. Advanced technologies such as robotics and artificial intelligence have minimized the need for manual labor and boosted productivity. The 3D approach optimizes space utilization, resulting in significant cost savings and increased storage capacity.

Real-time inventory tracking and optimization features empower businesses to make informed decisions and enhance their inventory management processes. The Cubic Storage Model is shifting the perception of warehouse management from a mere cost center to a strategic advantage.

Future Developments and Innovations in the Cubic Storage Model

The Cubic Storage Model continues to evolve with ongoing innovations aimed at further enhancing efficiency:

- Drones and Autonomous Vehicles: The integration of drones and autonomous vehicles in warehouse operations is being explored to increase productivity and reduce reliance on manual labor.

- Machine Learning Integration: Incorporating machine learning algorithms into inventory management systems can identify trends and patterns, optimizing warehouse operations through predictive analytics.

- Enhanced Robotics: Advances in robotics technology are enabling more versatile and efficient automation solutions for complex warehousing tasks.

Is the Cubic Storage Model Right for Your Business? A Comprehensive Guide

Before adopting the Cubic Storage Model, businesses should evaluate whether it aligns with their specific needs and operations. Consider the following factors:

- Type of Products: The Cubic Storage Model is particularly effective for high-density storage of small to medium-sized items.

- Warehouse Size: The 3D approach is most beneficial in larger warehouses with ample storage capacity.

- Budget: Implementing the Cubic Storage Model can be costly. Businesses must assess their financial capacity to support the initial investment.

- Operational Complexity: Complex business processes may require tailored solutions, and alternative warehouse management systems might be more suitable.

Expert Opinions on the Benefits and Drawbacks of the Cubic Storage Model

Industry experts widely recognize the Cubic Storage Model for its efficiency gains and cost savings. Many professionals highlight its ability to optimize space and streamline operations as key advantages. However, some experts caution about potential drawbacks, such as the high initial implementation costs and the extensive training required for employees.

Despite these challenges, the consensus among experts is that the benefits of the Cubic Storage Model outweigh the drawbacks for many businesses, solidifying its position as the new industry standard for warehousing operations.

Key Considerations for Choosing a Provider for Your Cubic Storage Needs

When selecting a provider for your Cubic Storage requirements, consider the following key factors:

- Experience and Expertise: Choose providers with a proven track record of successful Cubic Storage Model implementations.

- Technology and Equipment: Assess the provider's technology and equipment offerings to ensure they meet your specific operational needs.

- Support and Maintenance Services: Ensure the provider offers comprehensive support and maintenance services to address any issues post-implementation.

- Cost and Pricing Structure: Evaluate the provider's cost and pricing models to ensure they align with your budget and financial planning.

Comparing the Cubic Storage Model to Other Popular Warehouse Management Systems

Several warehouse management systems are available, each with its own set of advantages and disadvantages. Compared to traditional shelving and rack systems or Automated Storage and Retrieval Systems (AS/RS), the Cubic Storage Model offers unique benefits:

- 3D Approach: The Cubic Storage Model's 3D optimization provides superior space utilization compared to traditional 2D shelving systems.

- Real-Time Inventory Tracking: Advanced inventory management systems offer real-time tracking, which is often more sophisticated than those in conventional systems.

- Space Utilization: The Cubic Storage Model maximizes every inch of available space, whereas traditional systems may leave underutilized areas.

While the initial implementation costs of the Cubic Storage Model may be higher than other systems, the long-term cost savings and efficiency gains make it a worthwhile investment for many businesses.

In conclusion, the Cubic Storage Model is establishing itself as the new industry standard for warehouse management systems. By providing businesses with an efficient, accurate, and cost-effective way to manage inventory, the Cubic Storage Model enhances space utilization, reduces picking errors, and boosts operational efficiency, ultimately serving as a strategic advantage for businesses worldwide.