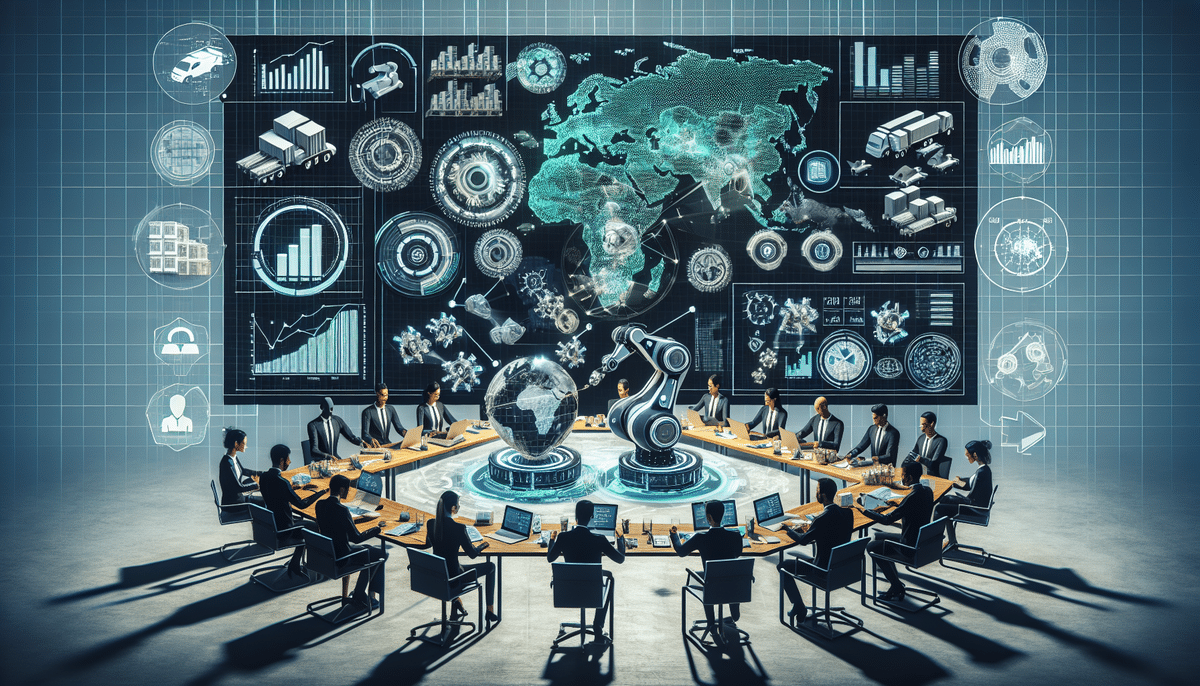

The Top 5 Strategies for Emerging Ecommerce Brands to Control Their Supply Chain Destiny

As ecommerce solidifies its position as a dominant force in the retail landscape, businesses must remain vigilant in managing their supply chains. Emerging ecommerce brands, in particular, face unique challenges as they strive to establish themselves and expand their market share. In this article, we explore the top five strategies these businesses can implement to control their supply chain destiny and maintain competitiveness in this rapidly evolving industry.

Understanding the Importance of Controlling Your Supply Chain

Controlling your supply chain is crucial for the success of your ecommerce business. It enables you to optimize operations, respond swiftly to changing customer demands, and reduce costs. Additionally, it provides greater visibility and control over inventory and order fulfillment, which are essential for meeting customer expectations regarding service and delivery times.

Moreover, having control over your supply chain ensures product quality. By closely collaborating with suppliers and monitoring their processes, you can identify and address issues such as defects or delays promptly. This proactive approach helps maintain a positive reputation and builds trust with customers, which is vital for long-term success in ecommerce.

- Operational Efficiency: Streamlined processes reduce costs and improve delivery times.

- Customer Satisfaction: Reliable fulfillment enhances the customer experience.

- Risk Mitigation: Greater control allows for quicker responses to disruptions.

Identifying the Key Challenges Faced by Emerging Ecommerce Brands in Supply Chain Management

Emerging ecommerce brands encounter several challenges in managing their supply chains, including:

- Lack of Experience: Limited expertise in supply chain management can lead to inefficiencies.

- Limited Resources: Smaller budgets restrict the ability to invest in advanced technologies.

- Access to Suppliers and Logistics Partners: Building reliable partnerships takes time and effort.

- Agility: Rapid industry growth demands adaptability to fluctuating demands and competition.

One of the most significant challenges is inventory management. With numerous SKUs and constantly changing demand, accurately forecasting and managing inventory levels can be difficult. This often results in stockouts, overstocking, and lost sales. To address this, ecommerce brands can leverage data analytics and machine learning algorithms to better predict demand and optimize inventory levels.

Building a Robust Supply Chain Strategy for Your Business

A robust supply chain strategy involves several critical steps:

- Identify Key Suppliers: Establish relationships with reliable suppliers to ensure consistent quality and supply.

- Develop Logistics Partnerships: Collaborate with dependable logistics partners to enhance delivery efficiency.

- Invest in Technology: Utilize inventory and order fulfillment technologies to streamline operations.

- Optimize Transportation Routes: Efficient routing reduces delivery times and costs.

- Establish Clear Communication Channels: Ensure all stakeholders are informed and aligned.

Additionally, having contingency plans for unexpected disruptions—such as natural disasters or supplier bankruptcies—is essential. This may involve diversifying your supplier base, maintaining safety stock levels, and having alternative transportation options. Regularly reviewing and updating your supply chain strategy ensures it remains effective and aligned with your business goals.

Using Technology to Streamline Your Supply Chain Operations

Technology plays a pivotal role in streamlining supply chain operations by providing enhanced visibility into inventory levels, order status, and transportation routes. Key technologies include:

- Inventory Management Software: Automates order fulfillment and inventory tracking.

- Transportation Management Systems (TMS): Optimizes delivery routes and reduces transportation costs.

- RFID Technology and Barcodes: Enables real-time tracking and monitoring of inventory and products.

- Predictive Analytics: Anticipates potential disruptions and adjusts operations accordingly.

- Cloud-Based Solutions: Offers flexibility and scalability, allowing for remote collaboration and real-time updates.

For instance, deploying RFID technology can significantly enhance inventory accuracy and reduce loss.

According to a McKinsey & Company study, businesses that implement predictive analytics in their supply chains see a 25% improvement in demand forecasting accuracy.

Leveraging Data and Analytics to Optimize Your Supply Chain Performance

Data and analytics offer invaluable insights for optimizing supply chain performance. By analyzing data on customer demand, order history, and inventory levels, businesses can:

- Accurately Forecast Demand: Improve procurement and logistics planning.

- Identify Cost Reduction Opportunities: Streamline operations to reduce expenses.

- Optimize Transportation Routes: Enhance delivery efficiency and reduce costs.

Furthermore, data analytics can enhance inventory management by identifying slow-moving items and adjusting ordering and stocking strategies, thereby reducing inventory carrying costs and preventing stockouts.

Monitoring supplier performance through data analytics allows businesses to assess delivery times, quality, and reliability, enabling informed decisions about supplier partnerships and risk mitigation strategies.

For more insights on leveraging data analytics, explore resources from the Harvard Business Review.

Collaborating with Key Stakeholders to Enhance Your Supply Chain Capabilities

Effective collaboration with key stakeholders is essential for enhancing supply chain capabilities. This includes building strong relationships with suppliers, logistics partners, and other stakeholders such as government agencies and industry organizations. Collaborative efforts can uncover opportunities for improvement and optimize operations for mutual benefit.

Establishing clear communication channels is a critical aspect of collaboration. This can involve:

- Regular meetings to discuss performance and challenges.

- Sharing data and information to ensure transparency.

- Setting up performance metrics to track progress.

Open and transparent communication allows for the swift resolution of issues and the implementation of necessary adjustments to improve supply chain capabilities.

Creating a Risk Management Plan for Your Supply Chain

A comprehensive risk management plan is vital to mitigate potential disruptions in your supply chain. This involves:

- Identifying Potential Risks: Natural disasters, supplier bankruptcies, labor strikes, etc.

- Developing Contingency Plans: Diversify supplier base, maintain safety stock, and have alternative transportation options.

- Establishing a Communication Plan: Keep all stakeholders informed about disruptions or delays.

Regularly reviewing and updating your risk management plan ensures it remains effective in addressing emerging risks as your business and industry evolve.

Measuring and Monitoring the Success of Your Supply Chain Strategy

Continuous improvement of your supply chain strategy relies on measuring and monitoring its success. Key performance indicators (KPIs) to track include:

- Delivery Times: Measures the speed of order fulfillment.

- Inventory Turnover: Indicates how efficiently inventory is managed.

- Order Accuracy: Reflects the precision of order fulfillment.

Regularly reviewing these metrics helps identify areas for improvement and optimize operations for greater efficiency. Additionally, tracking customer satisfaction through feedback can provide insights into how well your supply chain meets customer needs and expectations. Enhancing the customer experience leads to increased loyalty and business success.

For more on tracking KPIs, visit the Investopedia KPI Guide.

Case Studies: How Leading Ecommerce Brands Have Mastered Their Supply Chains

Several leading ecommerce brands have successfully mastered their supply chains by implementing advanced strategies and technologies. Companies like Amazon and Alibaba have invested heavily in technology solutions and established robust relationships with suppliers and logistics partners. Their continuous innovation in supply chain strategies offers valuable lessons for emerging ecommerce brands.

One key strategy employed by these industry leaders is the use of data analytics to optimize supply chain operations. By analyzing data on customer demand, inventory levels, and shipping times, they make informed decisions on sourcing, inventory management, and shipping methods. This results in faster delivery times, lower costs, and higher customer satisfaction.

Additionally, these companies prioritize sustainability in their supply chain operations. Initiatives to reduce waste, minimize carbon emissions, and promote ethical sourcing not only benefit the environment but also enhance brand reputation and attract socially conscious consumers.

For detailed case studies, explore resources from Business Insider and Alibaba Cloud.

Conclusion: The Future of Ecommerce and Its Impact on Supply Chain Management

As ecommerce continues to grow and evolve, so too will the challenges associated with managing supply chains. Emerging ecommerce brands must remain proactive by investing in technology solutions, fostering strong relationships with suppliers and logistics partners, and continuously optimizing their operations to stay competitive. These steps will enable them to achieve greater control over their supply chain destiny and establish themselves as leaders in this dynamic industry.

One of the key trends shaping the future of ecommerce and supply chain management is the increasing adoption of automation and artificial intelligence. Advanced technologies such as robotics, machine learning, and predictive analytics enable businesses to streamline operations, reduce costs, and enhance efficiency. For example, automated warehouses and fulfillment centers allow ecommerce companies to process orders faster and more accurately, while predictive analytics help anticipate demand and optimize inventory levels.

As these technologies continue to advance and become more accessible, they will play an increasingly significant role in shaping the future of ecommerce and supply chain management, driving innovation and growth across the industry.