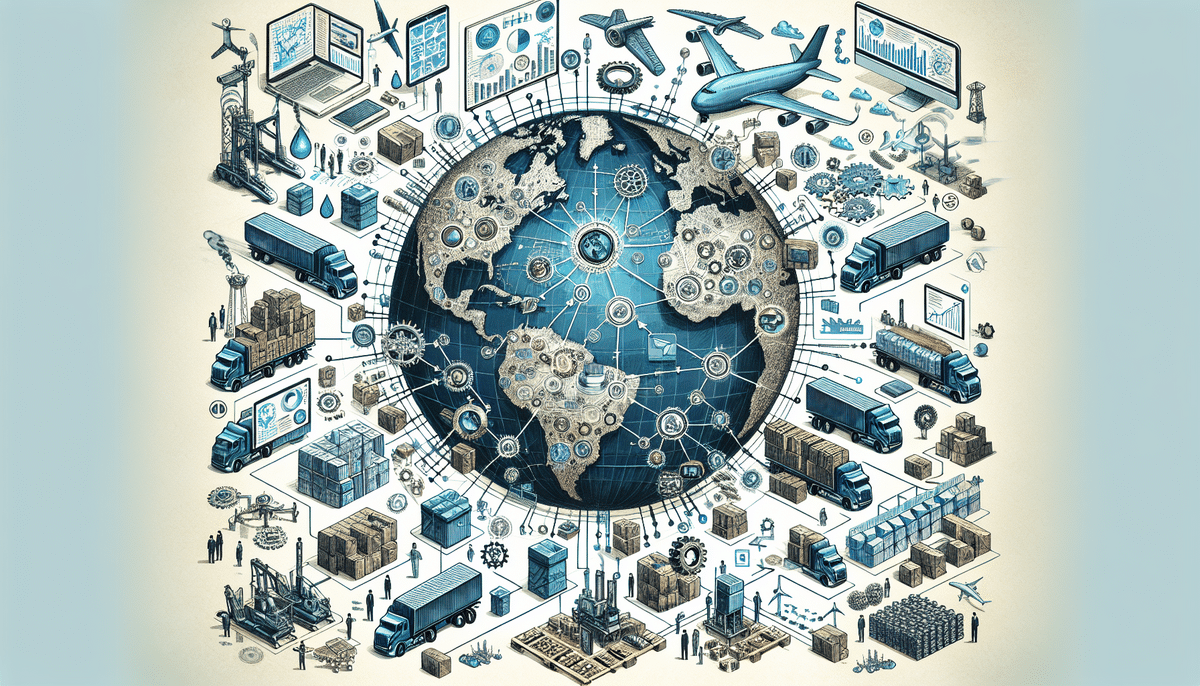

The Ultimate Supply Chain Management Resource Guide

Supply chain management (SCM) is a critical aspect of any business aiming to keep operations running smoothly and efficiently. In this resource guide, we explore the basics of supply chain management, its importance in business success, and key elements of successful SCM strategies. We also delve into the benefits of optimizing your supply chain, best practices in managing it, and the role of technology and innovation. Additionally, we examine sustainability practices, globalization, and future predictions. Finally, we conclude with a list of tools and resources to help you develop and implement effective supply chain management strategies.

Understanding the Basics of Supply Chain Management

At its core, SCM is the coordination and management of all activities involved in the production and delivery of products and services to customers. SCM begins with planning and procurement and spans to delivery and customer service. The goal of SCM is to ensure that all activities are executed in a timely, cost-effective, and quality manner.

One of the key components of SCM is inventory management. This involves tracking inventory levels, forecasting demand, and ensuring that the right products are available at the right time. Effective inventory management can help reduce costs and improve customer satisfaction by ensuring that products are always available when customers need them. According to a Supply Chain Digital report, companies that optimize inventory management can reduce holding costs by up to 20%.

Another important aspect of SCM is logistics management. This involves managing the transportation and storage of goods, as well as coordinating with suppliers and distributors. Effective logistics management can help reduce transportation costs, improve delivery times, and ensure that products are delivered to customers in good condition. According to the Investopedia, efficient logistics can lead to a 15% increase in overall business productivity.

The Importance of Effective Supply Chain Management for Business Success

While SCM may appear complex, it is essential for business success. Ineffective management can lead to delays, added costs, and dissatisfied customers. A properly functioning supply chain can improve customer service, increase efficiency, reduce costs, and drive innovation.

One of the key benefits of effective supply chain management is improved inventory management. By optimizing the flow of goods and materials, businesses can reduce excess inventory and avoid stockouts. This not only saves money but also ensures that customers receive their orders on time.

Another advantage of SCM is increased visibility and transparency. With the use of technology and data analytics, businesses can track their supply chain in real-time, identify potential issues, and make informed decisions. This level of visibility can also help companies identify opportunities for improvement and innovation. According to a Forbes article, data-driven supply chains are 3 times more likely to achieve above-average profitability.

Key Elements of a Successful Supply Chain Management Strategy

Developing an effective SCM strategy requires careful planning and execution. Key elements include:

- A clear vision and defined objectives

- Collaboration with suppliers and customers

- Efficient processes and workflows

- Data-driven decisions using analytics

- A focus on continuous improvement

Another important element is risk management. This involves identifying potential risks in the supply chain, such as natural disasters, political instability, or supplier bankruptcy, and developing contingency plans to mitigate these risks. Effective risk management can help ensure that the supply chain continues to function smoothly even in the face of unexpected disruptions.

Additionally, sustainability is becoming an increasingly important consideration in SCM. Companies are recognizing the importance of reducing their environmental impact and ensuring ethical practices throughout their supply chain. This may involve sourcing materials from sustainable sources, reducing waste and emissions, and ensuring fair labor practices throughout the supply chain.

Benefits of Optimizing Your Supply Chain

The benefits of effectively managing a supply chain are numerous. Optimizing your SCM can lead to:

- Reduced costs

- Increased efficiency

- Improved customer satisfaction

- A competitive advantage

- Enhanced resilience

Furthermore, a well-managed supply chain can enhance resilience, allowing businesses to respond quickly to disruptions and adapt to changing customer and market demands.

Another benefit is improved sustainability. By streamlining processes and reducing waste, businesses can minimize their environmental impact and contribute to a more sustainable future. This can also lead to cost savings, as sustainable practices often result in reduced energy and resource consumption. According to a McKinsey report, companies with sustainable supply chains experience a 10-15% cost reduction over time.

How to Develop Effective Supply Chain Management Strategies

Developing an effective SCM strategy requires a holistic approach. This process involves:

- Analyzing the current supply chain

- Identifying areas of improvement

- Developing a plan to implement necessary changes

- Ensuring communication and collaboration with stakeholders

One important aspect is considering the impact of technology. With the rise of digitalization, companies can leverage technology to optimize their supply chain processes. This includes using data analytics to identify trends and patterns, implementing automation to streamline operations, and utilizing software to improve communication and collaboration.

Another key factor is sustainability. Consumers are increasingly concerned about the environmental impact of the products they purchase, and companies are under pressure to reduce their carbon footprint. Developing a sustainable SCM strategy involves identifying ways to reduce waste, minimize transportation emissions, and source materials from environmentally responsible suppliers.

Common Challenges in Supply Chain Management and How to Overcome Them

Despite the best-laid plans, there will always be challenges when managing a supply chain. Common issues include:

- Supplier reliability

- Unplanned disruptions

- Poor logistics

- Inadequate technology

These challenges can be addressed by:

- Building strong supplier relationships

- Implementing contingency plans

- Developing logistics expertise

- Leveraging technology to improve visibility and communication

Another challenge is the lack of transparency and traceability. It can be difficult to track products and materials throughout the supply chain, leading to issues such as counterfeiting, quality control problems, and ethical concerns. To overcome this, companies can implement blockchain technology, which provides a secure and transparent way to track products and materials from the source to the end consumer. This can improve trust and accountability in the supply chain and help companies identify and address issues more quickly.

Best Practices in Managing Your Supply Chain

The following best practices can help optimize your supply chain:

- Collaborate with suppliers and customers to improve communication and reduce risk

- Utilize data to inform decision-making

- Implement automation to improve efficiency

- Invest in logistics to improve delivery times and reduce costs

- Focus on continuous improvement to remain competitive

Another important best practice is to diversify your supplier base. Relying on a single supplier can be risky, as disruptions in their operations can significantly impact your business. By working with multiple suppliers, you can spread out your risk and ensure a more stable supply chain.

Additionally, it's important to regularly review and update your supply chain strategy. As your business grows and evolves, your supply chain needs may change. By regularly assessing your supply chain and making necessary adjustments, you can ensure that it remains aligned with your business goals and objectives.

The Role of Technology in Supply Chain Management

Technology plays a critical role in SCM operations. It enables real-time tracking of products and inventory, improves communication and collaboration, and provides data-driven insights that drive decision-making. Popular technologies used in SCM include artificial intelligence (AI), blockchain, and the Internet of Things (IoT).

One of the key benefits of technology in SCM is increased efficiency. With the use of automated systems and advanced analytics, companies can optimize their supply chain processes and reduce waste. For example, predictive analytics can help companies anticipate demand and adjust their inventory levels accordingly, reducing the risk of overstocking or stockouts. Additionally, automation can streamline tasks such as order processing and shipping, freeing up time for employees to focus on more strategic activities. According to a PwC report, AI-powered supply chains can improve operational efficiency by up to 20%.

Trends and Innovations in Supply Chain Management

SCM innovations are constantly evolving, and companies must stay up to date to remain competitive. Emerging trends include:

- E-commerce

- Automation

- Enhanced customer service

E-commerce has revolutionized the way companies manage their supply chains. With the rise of online shopping, companies must now focus on delivering products quickly and efficiently to customers. This has led to the development of new technologies such as drones and autonomous vehicles, which can help streamline delivery processes.

Automation is another key trend in supply chain management. By automating tasks such as inventory management and order processing, companies can reduce costs and improve efficiency. This can also help reduce errors and improve accuracy, which is crucial in industries such as healthcare and pharmaceuticals.

Sustainable Practices in Supply Chain Management

Businesses are increasingly aware of their environmental impact, and SCM plays a critical role in implementing sustainable practices. Sustainable SCM practices include:

- Reducing waste

- Promoting recycling

- Reducing carbon emissions

Another important aspect is ethical sourcing. This involves ensuring that materials used in the supply chain are obtained from suppliers who follow ethical and sustainable practices, including fair labor practices, responsible sourcing of raw materials, and minimizing the environmental impact of production processes.

Furthermore, sustainable SCM involves reducing the overall environmental impact of transportation and logistics. This can be achieved through the use of alternative transportation methods, such as electric vehicles or trains, and optimizing delivery routes to reduce fuel consumption and emissions. Additionally, implementing sustainable packaging practices, such as using biodegradable materials or reducing packaging waste, contributes to a more sustainable supply chain. According to the United Nations Global Compact, sustainable supply chains can enhance brand reputation and customer loyalty.

Globalization and Its Impact on Supply Chain Management

The globalization of business has transformed the SCM landscape. Businesses must now consider a wide range of geopolitical, cultural, and economic factors when managing their supply chains. To effectively manage global supply chains, companies must:

- Build strong relationships with suppliers

- Invest in logistics

- Remain agile and flexible

One of the biggest challenges of managing a global supply chain is the increased risk of disruptions. Natural disasters, political instability, and trade disputes can all impact the flow of goods and materials. To mitigate these risks, companies must have contingency plans in place and diversify their supplier base.

Another important consideration in global supply chain management is sustainability. As consumers become more environmentally conscious, companies must ensure that their supply chains are ethical and sustainable. This includes reducing carbon emissions, minimizing waste, and ensuring fair labor practices throughout the supply chain.

Case Studies: Successful Companies That Mastered Their Supply Chains

Several companies have successfully optimized their supply chains and improved their bottom lines. Notable examples include:

- Amazon

- Walmart

- Zara

These companies have invested in state-of-the-art logistics, developed strong supplier relationships, and leveraged technology to streamline operations. For instance, Amazon's investment in automation and robotics has significantly enhanced their fulfillment efficiency.

Tools and Resources for Effective Supply Chain Management

There are numerous tools and resources available to businesses looking to improve their SCM. These include software platforms, industry associations, and consulting services. Some popular platforms include:

Additionally, industry associations such as the Council of Supply Chain Management Professionals (CSCMP) and the Institute of Supply Management (ISM) provide valuable resources and networking opportunities.

Future of Supply Chain Management: Predictions and Possibilities

The future of SCM is bright, with technology continuing to play a pivotal role in its evolution. Some predictions include:

- Increased use of automation to improve efficiency

- Emergence of blockchain to enhance transparency

- Continued focus on sustainability to reduce environmental impact

For example, the adoption of AI and machine learning is expected to further enhance demand forecasting and inventory management, making supply chains more resilient and responsive.

Conclusion

Effective SCM is essential for any business that wants to remain competitive and profitable. Optimizing your supply chain requires careful planning, collaboration, and investment in technology and logistics. By staying up to date with industry trends and leveraging the numerous tools and resources available, businesses can optimize their operations and achieve long-term success.