Introduction to E-Commerce and Warehouse Automation

E-commerce refers to the buying and selling of goods and services over the internet. One of the key challenges faced by e-commerce businesses is the efficient management of their inventory. Traditional methods of inventory management, such as manual tracking and counting, can be time-consuming, error-prone, and expensive. This is where warehouse automation comes in.

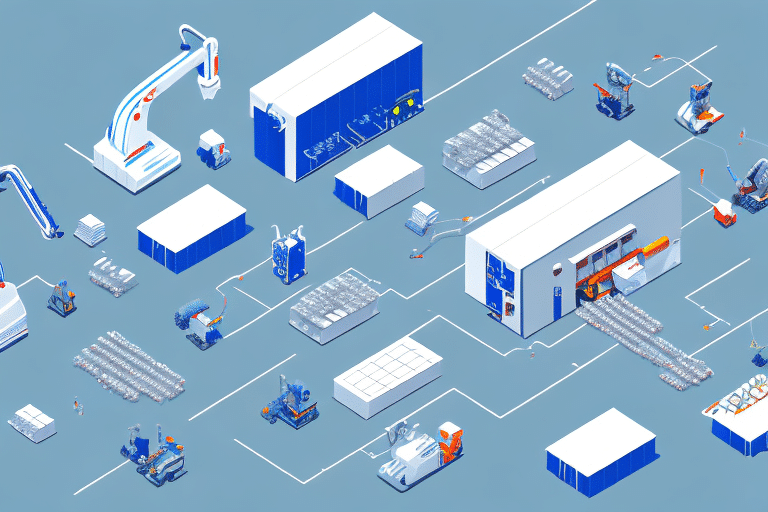

Warehouse automation involves the use of technology and software to streamline the process of inventory management. This can include automated storage and retrieval systems, conveyor belts, and robotic picking systems. According to a report by Gartner, the global warehouse automation market is expected to grow significantly in the coming years.

By implementing warehouse automation, e-commerce businesses can reduce the time and cost associated with managing their inventory, while also improving accuracy and efficiency. Another benefit of warehouse automation is the ability to scale operations more easily. As e-commerce businesses grow and expand, they may need to increase their inventory capacity and processing speed. With traditional manual methods, this can be a difficult and time-consuming process. However, with warehouse automation, businesses can quickly and easily add new technology and equipment to their operations, allowing them to keep up with demand and continue to grow.

Benefits of Warehouse Automation for E-Commerce Businesses

Warehouse automation solutions offer numerous benefits to e-commerce businesses, including increased efficiency, improved accuracy, and reduced labor costs. By automating their warehouse processes, businesses can streamline their operations and reduce their order fulfillment times. Automation can also help businesses reduce errors in their inventory management, resulting in fewer lost or damaged products and increased customer satisfaction.

In addition to these benefits, warehouse automation can also provide businesses with real-time data and analytics. This data can be used to optimize warehouse operations, such as identifying areas for improvement and predicting future demand. A study by McKinsey highlights how real-time data can lead to a 20% improvement in operational efficiency.

Furthermore, automation can help businesses meet the growing demand for faster and more accurate order fulfillment, which is essential in today's competitive e-commerce market. According to Statista, global e-commerce sales are projected to reach $6.54 trillion by 2023, underscoring the importance of efficient warehouse operations.

Key Warehouse Automation Solutions for E-Commerce in 2023

The following are the top warehouse automation solutions for e-commerce businesses in 2023:

1. Automated Storage and Retrieval Systems (AS/RS)

AS/RS utilizes computer-controlled systems to automatically store and retrieve products from shelving units. This solution is ideal for businesses that handle large quantities of products and require high-speed order fulfillment.

AS/RS can help businesses save space and reduce labor costs by eliminating the need for manual picking and storing of products. Additionally, it improves inventory accuracy and reduces the risk of errors in order fulfillment.

2. Autonomous Mobile Robots (AMRs)

AMRs are unmanned vehicles that can autonomously move, pick up, and transport goods throughout a warehouse. They provide flexibility and scalability for businesses, allowing them to adapt to changing demands.

AMRs enhance efficiency by navigating through warehouses without human intervention, optimizing routes, and reducing the time taken to transport goods.

3. Conveyor Systems

Conveyor systems are designed to automatically transport products from one location to another. They are ideal for businesses requiring high-speed order fulfillment and can be customized to fit a wide range of warehouse layouts.

Types of conveyor systems include belt conveyors, roller conveyors, and overhead conveyors, each offering unique advantages based on warehouse needs.

4. Automated Guided Vehicles (AGVs)

AGVs are similar to AMRs but are designed to transport larger and heavier products. They are ideal for moving products that are too heavy for manual handling.

AGVs increase efficiency by handling bulk movements without human intervention, reducing labor costs and minimizing accidents.

5. Pick-to-Light Systems

Pick-to-Light systems use light indicators to guide workers to the correct location in a warehouse to pick products. This technology enhances picking speed and accuracy.

By reducing the time spent searching for items, pick-to-light systems contribute to faster order fulfillment and improved worker productivity.

6. Automated Packaging Systems

Automated packaging systems use machines to package products for shipment. They are ideal for businesses that need to package products quickly and efficiently.

These systems reduce packaging time, ensure consistency, and minimize packaging errors, leading to cost savings and customer satisfaction.

7. Automated Sorting Systems

Automated sorting systems use machines to sort products based on their destination. They are ideal for processing a large number of orders quickly.

By automating the sorting process, businesses can handle higher order volumes with greater accuracy and less manual labor.

8. Automated Labeling Systems

Automated labeling systems use machines to print and apply labels to products. They ensure labels are applied quickly and accurately.

This automation reduces labeling errors, speeds up the shipping process, and maintains consistency across products.

9. Automated Inventory Management Systems

These systems use sensors and software to track inventory levels in real-time. They are essential for managing a large number of SKUs efficiently.

Automated inventory systems provide accurate stock data, minimize stockouts and overstock situations, and enhance overall inventory control.

10. Warehouse Management Systems (WMS)

WMS solutions use software to manage all aspects of a warehouse, including inventory, orders, and shipping. They are crucial for managing a high volume of orders and shipments.

A robust WMS can integrate with other automation solutions, providing a comprehensive system for efficient warehouse operations.

Factors to Consider Before Implementing Warehouse Automation Solutions

Before implementing warehouse automation solutions, businesses need to consider various factors to ensure they choose the right solution for their needs:

- Business Size and Growth: Assess the current size and projected growth of the business to determine the scalability of the automation solution.

- Operational Complexity: Evaluate the complexity of warehouse operations to select a system that addresses specific process requirements.

- Product Types and Volume: Consider the types of products handled and the volume of orders to choose appropriate automation tools.

- Budget: Determine the budget for automation projects, including initial investment and ongoing maintenance costs.

- Customization Needs: Identify whether a customized solution is required to meet unique operational needs or if a standardized system suffices.

- Vendor Support and Expertise: Select vendors with proven experience and a track record of successful implementations in the industry.

Additionally, businesses should consider the impact of automation on their workforce. While automation can increase efficiency and productivity, it may also lead to job displacement. It is important to have a plan in place to train and reassign employees who may be affected by the implementation of automation solutions.

Challenges in Implementing Warehouse Automation Solutions for E-Commerce Businesses

Implementing warehouse automation solutions can be challenging for e-commerce businesses, especially those new to the technology. Common challenges include:

- High Initial Costs: The upfront investment for automation technology can be significant, posing financial challenges for some businesses.

- Integration with Existing Systems: Ensuring that new automation solutions integrate seamlessly with existing warehouse management systems and processes can be complex.

- Workforce Adaptation: Adapting the workforce to work alongside automated systems requires training and change management.

- Technical Issues: Automation systems may encounter technical issues that require specialized knowledge to resolve, leading to potential downtime.

- Scalability: Ensuring that the chosen automation solutions can scale with business growth is essential to prevent future bottlenecks.

To overcome these challenges, businesses should carefully plan their automation projects, consult with automation experts, and choose reliable vendors with comprehensive support services.

Future Trends in Warehouse Automation for E-Commerce Businesses

The future of warehouse automation for e-commerce businesses looks promising, with advancements in technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) leading the way. These technologies will enable businesses to further streamline their operations, reduce costs, and improve customer satisfaction.

Some of the key future trends include:

- AI and Machine Learning: Enhanced decision-making and predictive analytics for inventory management and demand forecasting.

- IoT Integration: Improved asset tracking and management through connected devices and sensors.

- Advanced Robotics: More sophisticated robots capable of handling a wider range of tasks with greater precision.

- Augmented Reality (AR): AR tools for warehouse workers to improve picking accuracy and training efficiency.

- Blockchain Technology: Enhanced transparency and security in the supply chain through blockchain-based systems.

These trends will drive the next generation of warehouse automation, making warehouses smarter, more efficient, and highly responsive to the dynamic demands of the e-commerce market.

Conclusion and Recommendations for E-Commerce Businesses Planning to Implement Warehouse Automation Solutions

Warehouse automation solutions offer numerous benefits to e-commerce businesses and are essential for those looking to stay competitive in today's market. However, implementing these solutions can be challenging, and businesses need to carefully evaluate their needs and choose the right solution for their operations.

We recommend that businesses consult with automation experts and select vendors that have experience in their industry and a track record of success in implementing automation projects. Additionally, businesses should invest in employee training and develop a comprehensive implementation plan to ensure a smooth transition to automated warehouse operations.

By strategically adopting warehouse automation, e-commerce businesses can achieve greater efficiency, reduce costs, and enhance customer satisfaction, positioning themselves for sustained growth in the fast-evolving digital marketplace.