Understanding Box Dimensions: What You Need to Know

Accurate box dimensions are essential for various applications, particularly in shipping and storage. Proper measurements help prevent damage during transit, optimize storage space, and reduce costs. This article delves into the significance of box dimensions, methods for accurate measurement, and tips for selecting the right box size.

Why Box Dimensions Matter for Shipping and Storage

Choosing the correct box size is crucial for protecting items and managing costs. Boxes that are too small can cause damage to the contents, while oversized boxes lead to wasted space and higher shipping expenses.

Protection During Transit

Properly sized boxes minimize movement, reducing the risk of items colliding and breaking. This is particularly important for fragile or high-value items.

Cost Efficiency

Shipping companies often calculate costs based on dimensional weight—a pricing method that considers both the size and weight of the package. Using appropriately sized boxes can lower shipping fees.[1]

Optimizing Storage Space

Consistent box dimensions enable efficient stacking and organization in storage facilities, maximizing the use of available space.

The Importance of Accurate Measurements in Box Dimensions

Precision in measuring box dimensions ensures that the box fits the contents perfectly without excess space or tight constraints.

Preventing Additional Costs

Inaccurate measurements can lead to higher shipping costs or the need for additional packaging materials, both of which increase expenses.

Ensuring Safety

Properly measured boxes help in maintaining the integrity of the items by preventing compression or excessive movement during transit.

Enhancing Efficiency

Accurate measurements facilitate better inventory management and streamlined packing processes.

Types of Boxes and Their Standard Dimensions

Understanding the different types of boxes and their standard sizes is vital for selecting the right packaging solution.

Corrugated Boxes

Available in single-wall, double-wall, and triple-wall variants, corrugated boxes offer varying levels of strength and durability. They are commonly used for shipping a wide range of products.

Standard Sizes

- Small: Approximately 12" × 12" × 12"

- Medium: Approximately 18" × 16" × 18"

- Large: Approximately 24" × 18" × 24"

Custom Boxes

For unique or irregularly shaped items, custom box dimensions can provide a tailored fit, enhancing protection and presentation.

Material Considerations

The weight capacity of a box depends on its size and the materials used. For instance, double-wall corrugated cardboard can support heavier loads than single-wall variants.

How to Measure Box Length, Width, and Height Correctly

Accurate measurement is the foundation of selecting the right box. Follow these steps to ensure precision:

Tools You Need

- Measuring tape or ruler

- Caliper for measuring wall thickness

- Digital measuring tools for higher accuracy

Measurement Steps

- Measure the length from one end to the other.

- Measure the width from one side to the other.

- Measure the height from the bottom to the top.

Consider Material Thickness

Account for the thickness of the box material to determine the available internal space. This is especially important for boxes made of thicker materials like double-wall corrugated cardboard.

Tips for Choosing the Right Box Size for Your Needs

Selecting the appropriate box size involves several considerations to ensure the safety and efficiency of your shipping or storage operations.

Assess Item Dimensions and Weight

Choose a box that accommodates the size and weight of your items without excessive empty space or strain on the box structure.

Consider Padding and Cushioning

Allow extra space for protective materials like bubble wrap or foam to safeguard fragile items.

Check Carrier Requirements

Different carriers have specific size and weight restrictions. Verify these guidelines to avoid unexpected fees.[2]

Opt for Consistent Sizes

Using boxes of uniform dimensions can streamline packing processes and optimize storage space.

Common Mistakes to Avoid When Measuring Box Dimensions

Avoid these pitfalls to ensure accurate box selection:

- Measuring Outside Instead of Inside: Always use inner dimensions for accurate fitting.

- Rounding Up Dimensions: Avoid adding unnecessary space, which can lead to higher shipping costs.

- Neglecting Material Thickness: Failing to account for wall thickness can result in selecting boxes that are too small.

Double-check all measurements and consider having a second person verify them to enhance accuracy.

Tools and Techniques for Measuring Box Dimensions

Employ the right tools and methods to achieve precise measurements:

Essential Tools

- Measuring tape or rigid ruler

- Calipers for wall thickness

- Digital measuring devices for complex shapes

Effective Techniques

- Measure from the Center: For irregular boxes, measuring from the center can provide a balanced assessment.

- Diagonal Measurement: Measuring diagonally can help determine the overall size and fit.

- Multiple Measurements: Taking measurements at different points ensures consistency and accuracy.

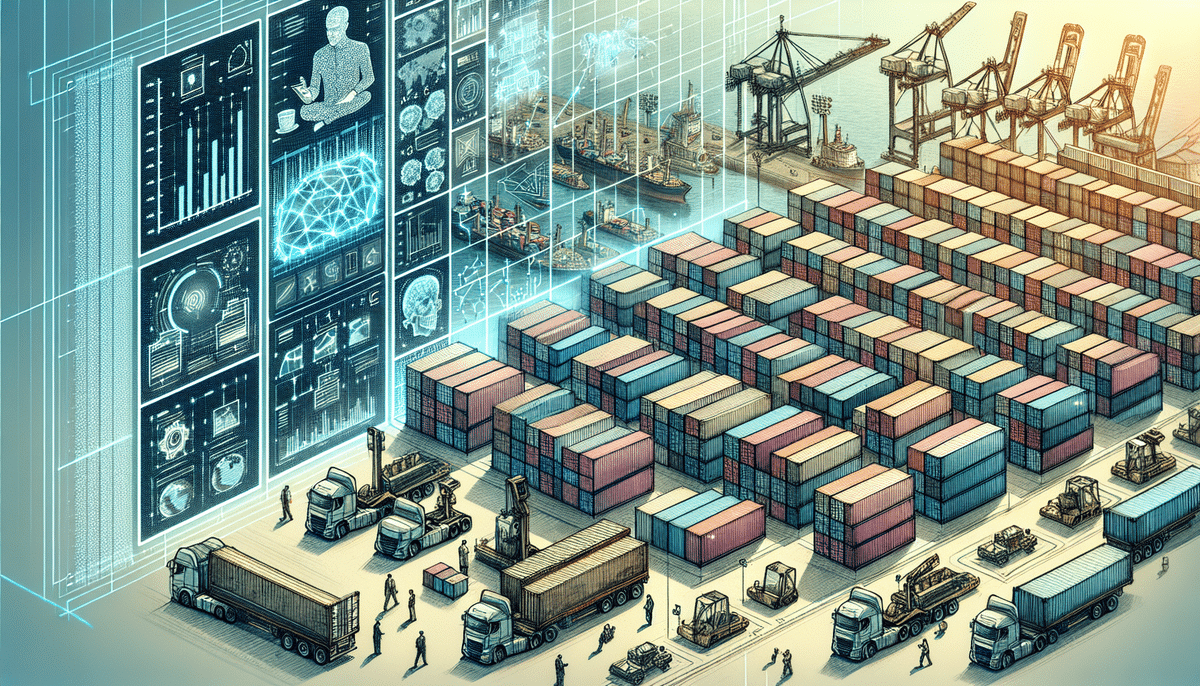

The Impact of Custom Box Dimensions on Shipping Costs

Custom box sizes can significantly influence shipping expenses due to dimensional weight pricing. However, they also offer benefits that can offset the costs.

Cost Considerations

Shipping carriers often charge based on the greater of actual weight or dimensional weight. Custom boxes that closely fit the item's dimensions can reduce dimensional weight charges.[3]

Maximizing Storage Efficiency

Custom dimensions optimize storage space, allowing for better organization and reduced warehousing costs.

Enhancing Brand Presentation

Unique box shapes can strengthen brand identity and improve customer experience, especially in retail and e-commerce.

How to Calculate the Volume and Weight of a Box Based on Its Dimensions

Understanding the volume and weight calculations helps in selecting the right packaging and estimating shipping costs.

Volume Calculation

Use the formula: Volume = Length × Width × Height. For example, a box measuring 18" × 16" × 18" has a volume of 5,184 cubic inches.

Weight Calculation

To determine the box's weight, multiply the material's weight per unit volume by the total volume. For instance, a single-wall corrugated box material might weigh approximately 0.005 lbs per cubic inch, resulting in a box weight of about 25.92 lbs.[4]

Dimensional Weight

Dimensional weight = (Length × Width × Height) / Divisor. The divisor varies by carrier; for example, UPS uses 139 for domestic shipments.[5]

Understanding the Difference Between Inside and Outside Box Dimensions

Distinguishing between inside and outside dimensions is vital for accurate box selection.

Inside Dimensions

These refer to the internal space available within the box, critical for determining if the items will fit properly.

Outside Dimensions

These measurements include the box's external size, which affects storage, stacking, and shipping costs.

Why It Matters

Using inside dimensions ensures your items fit with necessary padding, while outside dimensions impact logistical considerations like shipping rates and storage space.

Innovations in Box Design: Dimensional Weight Pricing Strategies

Recent advancements in box design aim to address the challenges posed by dimensional weight pricing.

Collapsible Boxes

Facilitates easy storage and reduces shipping space when the boxes are empty, leading to cost savings.

Optimized Sizing

Designing boxes that closely match item dimensions minimizes wasted space and lowers shipping costs.

Advanced Materials

Use of stronger, lighter materials allows for durable yet lightweight boxes, balancing protection and cost.

Smart Packaging Solutions

Integrating technology into packaging, such as RFID tags, enhances tracking and inventory management.

How to Maximize Storage Space with Efficient Box Dimensions

Efficient box dimensions contribute to better space utilization in storage facilities and warehouses.

Stacking Strategy

Uniform box sizes facilitate stable stacking, reducing the risk of toppling and optimizing vertical space.

Modular Storage Systems

Using boxes with standardized dimensions allows integration with modular shelving and storage systems.

Space Planning

Strategic arrangement of boxes based on size and frequency of access ensures maximum space utilization and accessibility.

Best Practices for Labeling Boxes with Accurate Dimensions

Proper labeling of boxes with dimensions is essential for efficient handling and shipping.

Clear and Visible Labels

Use large, legible fonts and place labels on multiple sides of the box to ensure visibility from different angles.

Include Essential Information

Labels should display the inside dimensions, weight, and handling instructions to facilitate accurate shipping and storage.

Standardized Labeling Formats

Adopt a consistent labeling system to streamline processes and reduce errors.[6]

Use of Barcode and RFID Technology

Incorporating barcodes or RFID tags into labels enhances tracking and inventory management capabilities.

Conclusion

Understanding and accurately measuring box dimensions is fundamental for efficient shipping and storage operations. Properly sized boxes protect items, optimize space, and reduce costs. By selecting the right box types, employing precise measurement techniques, and adhering to best practices for labeling, businesses can enhance their logistical efficiency and ensure the safe transport of goods.

For more information on optimizing your packaging processes, refer to reputable sources such as the Packaging Digest and the Inbound Logistics websites.

---

Sources: