Understanding Full Kitting: Definitions, Processes, and Benefits

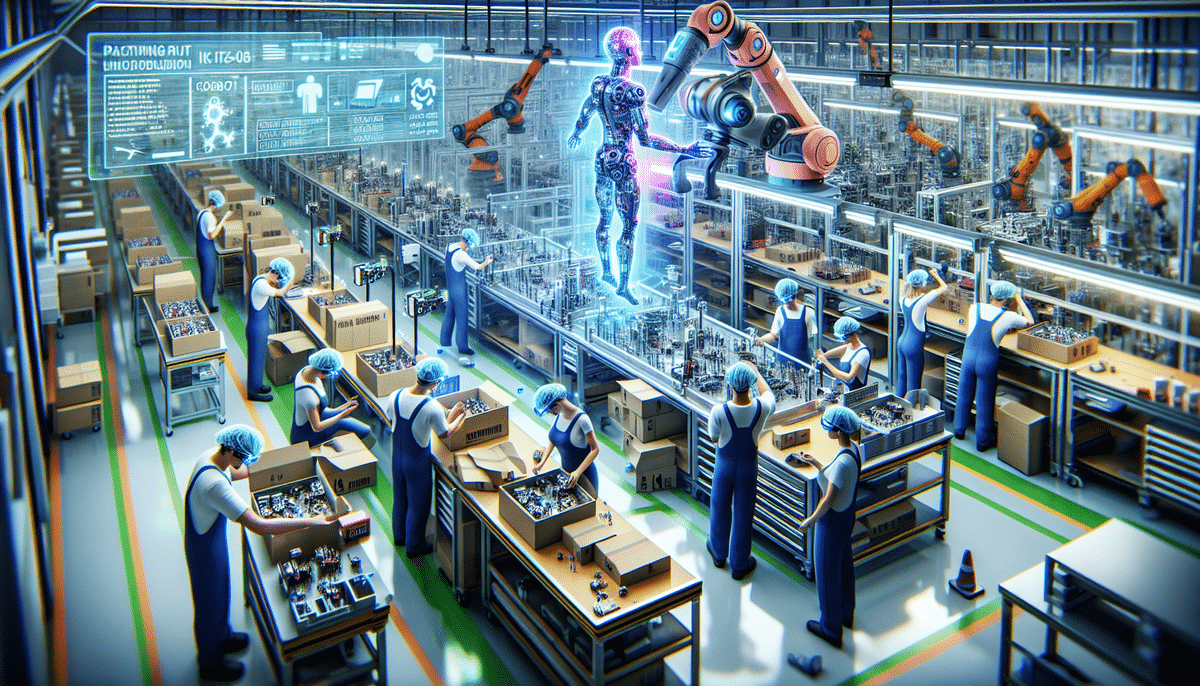

In today's fast-paced manufacturing industry, maximizing efficiency is key to staying competitive. Full kitting, also known as kit assembly or kit packaging, is a process that has gained immense popularity among manufacturers for its ability to streamline production and simplify inventory management. In this article, we will delve deep into the world of full kitting, discussing key definitions, processes, and benefits associated with this invaluable manufacturing tool.

What is Full Kitting?

Full kitting is a process that involves grouping together a series of parts, components, or materials required for the production of a certain product or assembly. This is done in a predetermined sequence and packaged as a kit that is delivered to the production line for easy assembly. The kits usually include all the necessary parts in the required quantities, along with their respective assembly instructions.

Full kitting is a popular method used in manufacturing and assembly industries to streamline the production process. By providing all the necessary parts in a kit, it reduces the time and effort required to gather and organize the components needed for assembly. This method also helps to minimize errors and reduce waste, as the kits are pre-packaged with the exact quantities required for each assembly. Full kitting is commonly used in industries such as automotive, electronics, and aerospace, where precision and efficiency are crucial to meeting production targets and maintaining quality standards.

The History of Full Kitting

Although full kitting has become increasingly popular in recent years, its roots can be traced back to the early years of the automotive industry. Manufacturers such as Ford and General Motors began using kits to streamline the production process of their vehicles and reduce waste. Today, full kitting is used across a range of industries including aerospace, electronics, medical equipment, and more.

In addition to its use in manufacturing, full kitting has also become a popular practice in the world of e-commerce. Online retailers use kits to bundle products together, offering customers a convenient and cost-effective way to purchase multiple items at once. This has become especially popular in the beauty and skincare industry, where companies offer curated kits of their products for customers to try out and purchase.

The Different Types of Full Kitting

There are several types of full kitting processes used in manufacturing:

- Build-to-Order: Kits are assembled based on customer orders, allowing for customization and flexibility.

- Build-to-Stock: Kits are assembled in advance and held in inventory until needed, ensuring quick availability.

- Hybrid Kitting: A combination of build-to-order and build-to-stock processes, balancing customization with efficiency.

- Just-In-Time (JIT) Kitting: Kits are assembled and delivered to the production line just in time for use, reducing inventory costs and improving efficiency.

JIT kitting requires careful planning and coordination to ensure that the kits are delivered on time and in the correct quantities, leveraging technologies such as Manufacturing Execution Systems (MES) and real-time inventory tracking.

The Advantages of Full Kitting

One of the most significant advantages of full kitting is the reduction in inventory carrying costs. By consolidating several parts into one kit, manufacturers can reduce the number of individual parts required to manufacture a product and keep less inventory on hand. This results in lower storage costs and reduced risk of obsolescence. According to a study by McKinsey & Company, implementing kitting strategies can reduce inventory costs by up to 20%.

Full kitting also minimizes the time required to locate, handle, and transport multiple parts to the production line, which increases efficiency and reduces the potential for errors.

Another advantage of full kitting is that it simplifies the assembly process. With all the necessary parts in one kit, workers can easily identify and access the components they need, reducing the time and effort required to assemble the product. This can lead to faster production times and increased output.

Full kitting can also improve quality control. By bundling all the necessary parts together, manufacturers can ensure that each kit contains the correct components and that all parts are inspected and tested before being included in the kit. This reduces the risk of errors and defects in the final product, which can improve customer satisfaction and reduce the need for costly rework or returns.

The Role of Technology in Full Kitting

Technology has played a vital role in the evolution of full kitting processes. Manufacturing Execution Systems (MES) are used to manage inventory levels and production schedules to ensure that the required kit components are available when needed. Barcode scanning and RFID tagging are often used to track kits throughout the production process, ensuring accuracy and providing real-time updates on inventory levels. Automated kitting systems are also used to assemble and pack kits, reducing the potential for human error and increasing speed and accuracy.

In addition to these technologies, Virtual Reality (VR) and Augmented Reality (AR) are also being explored as potential tools for full kitting. VR can be used to simulate the assembly process, allowing workers to practice and perfect their techniques before working with physical components. AR can be used to provide workers with real-time instructions and guidance during the assembly process, reducing the need for printed instructions and minimizing errors. As technology continues to advance, it is likely that even more innovative solutions will be developed to further streamline and optimize full kitting processes.

How Full Kitting Reduces Costs and Increases Efficiency

Full kitting offers significant cost savings by reducing inventory carrying costs, minimizing waste generated by excess parts, and increasing efficiency on the production line. The consolidation of parts leads to streamlined processes, fewer errors, and fewer assembly steps, resulting in a faster, more efficient production process. Additionally, full kitting simplifies the management of inventory and reduces the amount of paperwork required for tracking, freeing up valuable time and resources that can be used elsewhere in the manufacturing process.

Another benefit of full kitting is improved control over the quality of the final product. By having all the necessary parts in one kit, it becomes easier to ensure that all components are present and in good condition before assembly. This reduces the risk of defects and rework, which can be costly and time-consuming.

Furthermore, full kitting can also enhance customer satisfaction. With all the necessary parts in one kit, assembly and delivery times can be reduced, leading to faster turnaround times for orders. This helps companies meet customer demands more quickly and efficiently, resulting in increased customer loyalty and repeat business.

The Benefits and Drawbacks of Outsourcing Full Kitting Services

Outsourcing full kitting services can offer several benefits, including cost reduction, as manufacturers do not need to invest in expensive automated kitting equipment or occupy valuable warehouse space. Outsourcing can also provide access to specialized expertise and knowledge, particularly for rare or hard-to-find parts. However, there are potential drawbacks to consider.

One disadvantage is the potential loss of control over the quality of kits, as well as decreased flexibility in terms of scheduling and customization. Additionally, outsourcing may lead to communication breakdowns between the manufacturer and the service provider, resulting in delays and errors in the final product. Companies that require a high level of customization or have unique packaging requirements may find outsourcing less viable. It is essential for manufacturers to carefully weigh the pros and cons of outsourcing before making a decision.

Best Practices for Implementing Full Kitting in Your Business

Implementing full kitting in your business requires careful planning, execution, and ongoing management. Here are some best practices to consider:

- Start Small: Begin with simpler kitting processes and assess performance metrics before scaling up.

- Effective Communication: Ensure clear communication between all involved parties, including suppliers, manufacturers, and kitting service providers.

- Regular Reviews: Continuously review processes and adjust strategies to optimize efficiency and cost savings.

- Select the Right Provider: Choose a kitting service provider with industry experience and the capability to offer customized solutions.

- Cost Management: Develop a comprehensive budget that accounts for all relevant expenses, including labor, materials, and equipment.

By adhering to these best practices, businesses can effectively implement full kitting operations that are both efficient and profitable.

How to Choose the Right Full Kitting Provider for Your Business Needs

Choosing the right kitting provider for your business requires careful consideration of several factors:

- Expertise and Experience: Evaluate the provider's experience in your specific industry and their ability to handle your unique requirements.

- Reputation: Research the provider's reputation by requesting references and reviewing client testimonials.

- Technological Capabilities: Ensure the provider utilizes advanced technologies like automated kitting systems, barcode scanning, and RFID tagging.

- Scalability: The provider should be able to scale their services to match your business growth and fluctuating demands.

- Pricing Structure: Review the provider's pricing to ensure it aligns with your budget and offers good value for the services provided.

Conduct thorough research, request references, and review pricing structures to make an informed decision that best fits your business needs.

Common Challenges and Solutions in Full Kitting Processes

Like any manufacturing process, full kitting can present challenges that need to be addressed:

- Managing Lead Times: Implement advanced scheduling software to better predict and manage lead times.

- Maintaining Quality Control: Establish stringent quality control protocols to ensure all components meet required standards.

- Handling Production Schedule Changes: Develop contingency plans to accommodate unexpected changes in production schedules.

Addressing these challenges requires proactive strategies and the integration of reliable technologies to ensure smooth and efficient full kitting operations.

Case Studies: Successful Implementation of Full Kitting in Various Industries

Several industries have successfully implemented full kitting into their production processes, including automotive, medical, and aerospace sectors. For example, Boeing uses full kitting to build its 787 Dreamliner, which requires over two million individual parts. By using a kitting solution, Boeing has been able to reduce assembly time and minimize errors, significantly enhancing their production efficiency.

In the electronics industry, companies like Apple use full kitting to manage the assembly of complex devices, ensuring that each component is accurately placed and assembled, leading to high-quality products that meet customer expectations.

Future Trends and Innovations in the Field of Full Kitting

The field of full kitting is constantly evolving, with new technologies and approaches emerging regularly. Key trends and innovations include:

- Augmented Reality (AR) and Virtual Reality (VR): These technologies are being used to enhance the kitting process by providing immersive training and real-time assembly guidance.

- Artificial Intelligence (AI) and Machine Learning: AI is being utilized for inventory management and kitting optimization, enabling predictive analytics and smarter decision-making.

- 3D Printing: On-demand kit assembly and customization are becoming possible with 3D printing, allowing for greater flexibility and rapid prototyping.

- Automation and Robotics: Increased automation in kitting processes is leading to higher precision, faster assembly times, and reduced labor costs.

As these technologies continue to advance, manufacturers can expect even more innovative solutions to further streamline and optimize full kitting processes, driving greater efficiency and competitiveness in the manufacturing industry.

Full kitting is a valuable tool in the manufacturing industry, offering significant benefits in terms of cost savings, efficiency, and inventory management. By understanding the key definitions, processes, and benefits associated with full kitting, manufacturers can implement this approach to optimize their production processes and stay competitive in the ever-changing world of manufacturing.