Understanding Minimum Order Quantity (MOQ) Requirements

If you're running a business that involves purchasing goods from suppliers, you've likely come across the term Minimum Order Quantity or MOQ. MOQ refers to the minimum number of units of a product that a supplier is willing to sell in a single order. MOQ can vary significantly depending on the supplier, product type, and industry. In this article, we'll discuss the various aspects of MOQ and how it impacts businesses.

Why MOQ is Important for Businesses

MOQ is an essential aspect of procurement for businesses as it determines the quantity of goods that they need to purchase at a time. MOQ provides suppliers with the ability to sell their products in a cost-effective manner by eliminating the need for them to package, ship, and handle small quantities of goods.

For businesses, MOQ can impact their ability to secure a reliable supply of goods, supplier relationships, and the availability of products. Failing to meet MOQ requirements can result in delays in receiving inventory or even the inability to acquire specific products from a supplier. Similarly, ordering too much inventory to meet MOQ can lead to overstocking, which can eventually result in product obsolescence and loss of profit.

Moreover, MOQ can also affect a business's cash flow. Purchasing large quantities of goods to meet MOQ requirements can tie up a significant amount of capital, which can be detrimental to a business's financial health. On the other hand, ordering smaller quantities of goods to avoid meeting MOQ requirements can result in higher unit costs, which can also impact a business's profitability. Therefore, it is crucial for businesses to carefully consider their MOQ requirements and strike a balance between meeting supplier requirements and managing their inventory and cash flow effectively.

According to a Forbes Business Council article, effectively managing MOQs can improve supplier relationships and lead to better negotiation terms, ultimately fostering business growth.

Different Types of MOQs and Their Benefits

There are various types of MOQs that are commonly used in different industries. The most common types include:

- Minimum Dollar Value MOQ: Suppliers set a minimum dollar amount that merchants must spend per order.

- Unit Quantity MOQ: Refers to the minimum number of units per order.

- Volume MOQ: Based on the total volume of the order.

- Batch Quantity MOQ: Set based on the number of units produced in a single production run.

Suppliers typically offer discounts for bulk orders, and with MOQ, businesses can take advantage of these discounts, resulting in significant cost savings in the long run. Additionally, placing larger orders can help businesses improve their relationships with their suppliers and potentially gain preferential treatment.

Another benefit of MOQs is that they can help businesses manage their inventory more efficiently. By placing larger orders, businesses can reduce the frequency of ordering and receiving shipments, saving time and resources. MOQs can also assist in planning production schedules more effectively, as businesses can anticipate product demand and adjust their production accordingly.

According to Harvard Business Review, optimizing MOQ strategies can lead to enhanced supply chain efficiency and reduced operational costs.

Examples of MOQs in Various Industries

The MOQ requirements can vary significantly depending on the industry and type of product. For instance:

- Fashion Industry: MOQs can range from as few as 10 pieces to as many as 500 pieces, depending on the design and fabric choices.

- Electronics Industry: Suppliers may require a minimum order of 1,000 units per order.

- Food Industry: MOQs can range from a few pallets to full container loads.

- Promotional Products Industry: Suppliers may require a minimum order of 100 or 250 units per order, especially for customized items.

Typically, MOQs are set based on manufacturers' production costs, and businesses must ensure that the MOQ they agree on is justified by the margins they expect to earn on their products.

In the promotional products industry, for example, customization costs are high. By setting a minimum order quantity, suppliers can cover their setup costs and maintain profitability.

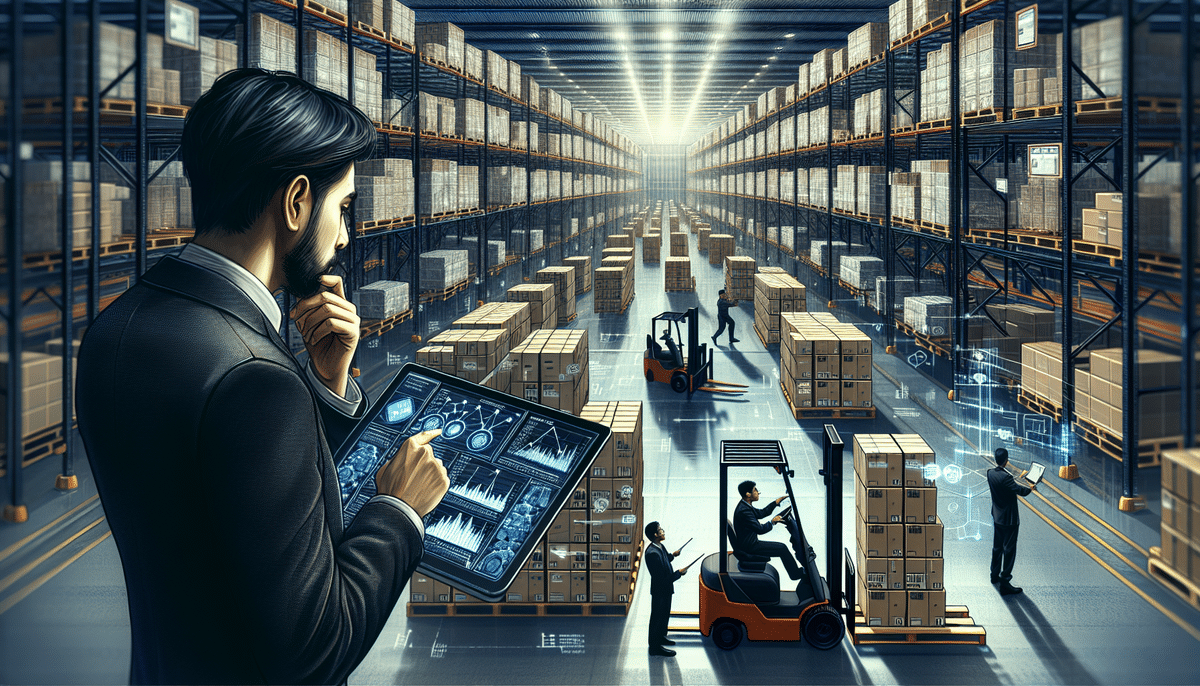

How to Determine the Right MOQ for Your Business

Determining the right MOQ involves balancing the cost savings of bulk purchases with the risks of overstocking. Key factors to consider include:

- Product Demand: High-demand products may warrant larger orders to prevent stockouts.

- Order Frequency: Frequent ordering can mitigate the need for large MOQs.

- Lead Time: Longer lead times may require higher MOQs to ensure continuous stock.

- Warehouse Capacity: Adequate storage space is essential to handle larger inventories.

- Cost of Goods Sold (COGS): Higher COGS may necessitate lower MOQs to avoid tying up too much capital.

For products with high demand, placing larger orders can help avoid stockouts and capitalize on bulk discounts. Conversely, for products with uncertain demand, smaller MOQs may reduce the risk of overstocking.

Understanding your business's financial health and inventory capacity is crucial in setting MOQs that support both operational efficiency and profitability.

Negotiating with Suppliers to Meet MOQ Requirements

Oftentimes, businesses can negotiate with suppliers to meet MOQ requirements. Effective negotiation strategies include:

- Long-Term Contracts: Committing to a long-term relationship can incentivize suppliers to lower MOQs.

- Flexible Payment Terms: Offering favorable payment terms can persuade suppliers to accommodate lower MOQs.

- Alternative Solutions: Exploring options like drop shipping or partnering with intermediaries to meet MOQ demands.

Working with intermediaries, such as wholesalers or distributors, can help businesses meet MOQ requirements or negotiate on their behalf. It's essential to discuss your constraints openly and seek solutions that foster a win-win relationship with suppliers.

According to Inc. Magazine, establishing clear communication and demonstrating commitment can lead to more flexible MOQ arrangements.

Common Challenges Faced When Dealing with MOQs

Businesses may encounter several challenges when dealing with MOQs, including:

- Financial Constraints: Inability to meet large MOQs due to limited capital.

- Lack of Warehouse Space: Insufficient storage can make managing large inventories difficult.

- Uncertain Demand: Predicting product demand can be challenging, leading to overstocking or understocking.

Overstocking can result in increased storage costs and potential product obsolescence, while understocking can lead to missed sales opportunities and damaged customer relationships.

To mitigate these challenges, it's critical to perform an in-depth analysis of your business's needs, capacity, and constraints before committing to an MOQ. Utilizing demand forecasting tools and maintaining flexibility in inventory management can also help address these issues.

Alternatives to Meeting MOQs

Businesses may explore alternative solutions to meet MOQ requirements, such as:

- Drop Shipping: A third-party supplier handles manufacturing, inventory, and shipping, allowing businesses to order products on a per-order basis without purchasing in bulk.

- Outsourcing: Partnering with third-party manufacturers to produce smaller batches, reducing the need for large upfront orders.

Drop shipping can enhance cash flow and reduce inventory risks, while outsourcing can provide more flexibility in production schedules. However, it's important to ensure that quality remains consistent when utilizing these alternatives, as variability can affect brand reputation.

According to a study by Statista, the drop shipping market is expected to grow significantly, highlighting its viability as an alternative to traditional MOQ requirements.

Impact of MOQ on Product Pricing and Profit Margins

MOQ has a significant impact on product pricing and profit margins. When businesses place larger orders, they can negotiate a lower price per unit, resulting in a reduced cost of goods sold (COGS). This allows businesses to set competitive market prices while maintaining healthy profit margins.

Setting the right market price is crucial for maintaining brand reputation and driving sales volume, ultimately leading to higher profits. However, overstocking can increase storage costs, decrease margins, and reduce overall profitability. Therefore, finding the right balance between MOQ and supply demand is essential for optimizing profit margins.

Data from Business.com suggests that small adjustments in MOQ can significantly influence product pricing strategies and overall financial performance.

How to Avoid Overstocking or Understocking Due to MOQ Requirements

Effective inventory management is key to avoiding overstocking and understocking. Strategies include:

- Demand Forecasting: Utilize data analytics to predict product demand accurately.

- Lead Time Management: Understand supplier lead times to plan orders accordingly.

- Reorder Points: Establish reorder points to trigger timely restocking.

- Inventory Management Software: Implement software solutions to track and optimize inventory levels.

Additionally, adopting agile production methods can enable flexible manufacturing processes that respond quickly to changing market demands. Regularly analyzing supply chain performance can further enhance inventory management practices.

Research by McKinsey & Company highlights the importance of advanced inventory management techniques in mitigating the risks associated with MOQs.

Understanding the Relationship Between MOQ and Lead Time

There is a significant relationship between MOQ and lead time—the time between placing an order and receiving the inventory. Generally:

- Long Lead Times: Often require higher MOQs to ensure sufficient inventory during extended intervals.

- Short Lead Times: Allow for lower MOQs, enabling more frequent ordering without overstocking.

Understanding this relationship helps businesses optimize their supply chain and inventory management. For instance, products with long lead times benefit from higher MOQs to maintain consistent stock levels, while those with short lead times can maintain lower MOQs and adapt more readily to market changes.

Insights from Supply Chain Digital suggest that balancing MOQ and lead time is crucial for maintaining an efficient and responsive supply chain.

Tips for Managing Inventory with MOQ Constraints

To effectively manage inventory under MOQ constraints, consider the following tips:

- Maintain Accurate Inventory Records: Track inventory levels meticulously to avoid discrepancies.

- Forecast Demand: Utilize forecasting tools to predict future product demand accurately.

- Communicate with Suppliers: Maintain open communication channels to ensure lead times and MOQ requirements are understood and met.

- Adopt Flexible Inventory Management: Implement agile strategies that allow quick adaptation to market changes.

Implementing these strategies can help businesses minimize the risks associated with MOQ requirements and maintain optimal inventory levels.

Industry experts from Inventory Magazine emphasize the importance of accurate forecasting and supplier communication in effective inventory management.

How to Monitor and Evaluate the Effectiveness of Your MOQ Strategy

The effectiveness of an MOQ strategy can be gauged using various metrics, including:

- Sales Volume: Tracking sales can indicate whether inventory levels meet market demand.

- Profit Margins: Monitoring margins helps assess the financial impact of MOQ decisions.

- Customer Satisfaction: Customer feedback can reveal if stock levels are meeting expectations.

Regularly reviewing these metrics allows businesses to adjust their MOQ strategies as needed. Utilizing data analytics tools can provide deeper insights into supply chain performance, brand reputation, and overall profitability.

According to Analytics Vidhya, leveraging data analytics is critical for making informed decisions and optimizing MOQ strategies.

Future Trends and Innovations in Minimum Order Quantity Requirements

The landscape of MOQs is evolving with advancements in technology and changing market dynamics. Emerging trends include:

- Micro-MOQs: Allowing businesses to purchase smaller quantities to test market demand without significant upfront investments.

- 3D Printing: Enabling on-demand production, reducing the need for large MOQs.

- Flexible MOQ Strategies: Suppliers adopting dynamic MOQs based on real-time demand forecasts rather than fixed quantities.

These innovations help businesses reduce capital tied up in inventory, respond more swiftly to market changes, and enhance overall supply chain flexibility.

A report by Gartner highlights the growing adoption of flexible MOQ strategies as a response to increased market volatility and the demand for greater supply chain agility.

Conclusion

MOQ is a fundamental aspect of the procurement process for businesses, determining the minimum quantity of goods that a supplier is willing to sell in a single order. MOQs can significantly impact a business's ability to secure a reliable supply of goods, maintain supplier relationships, and ensure product availability.

Understanding the various types of MOQs, negotiating effectively with suppliers, managing inventory levels, and accurately forecasting demand are essential components of an optimized MOQ strategy. By effectively managing MOQs, businesses can leverage bulk discounts, maintain brand reputation, increase sales volume, and enhance profitability.

For more insights on procurement strategies and supply chain management, visit Shipscience.