Understanding the Benefits of Reverse Logistics

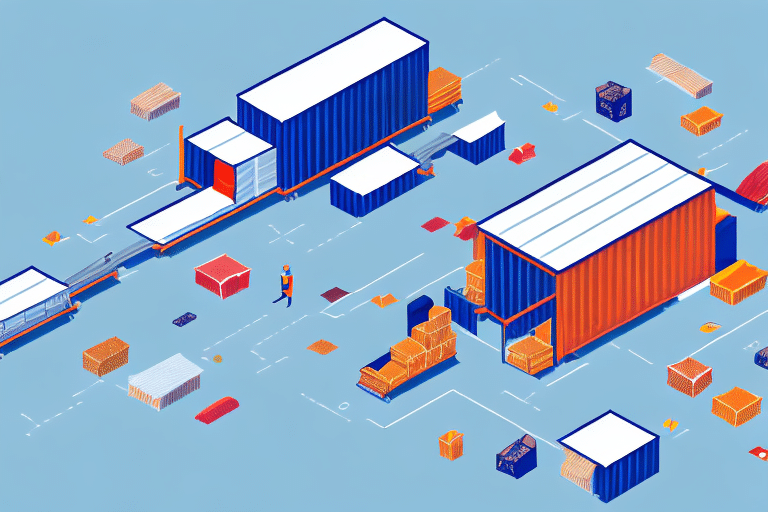

In recent years, reverse logistics has emerged as a crucial component of supply chain management. Simply put, reverse logistics involves managing the return of goods from end users to their origin. This process encompasses products that are damaged, expired, or no longer needed, as well as packaging materials or other components that can be reused or recycled. The significance of reverse logistics lies in its contributions to environmental sustainability, cost savings, and enhanced customer satisfaction.

What is Reverse Logistics and Why is it Important?

At its core, reverse logistics manages the flow of goods and materials from end users back to the point of origin. This includes activities such as product returns, repairs and refurbishment, recycling and disposal, and asset recovery. Traditionally viewed as a cost center, reverse logistics is now recognized as a strategic function that can help companies minimize waste, lower costs, and boost customer satisfaction.

One key benefit of effective reverse logistics is the ability to recover value from returned or unused products. By refurbishing and reselling these items, companies can recoup some of the initial sale costs and reduce landfill waste. Additionally, offering a hassle-free return process can significantly improve customer satisfaction and loyalty, leading to increased sales and revenue.

Industries with strict disposal regulations, such as electronics and pharmaceuticals, particularly benefit from robust reverse logistics. Proper disposal of these products helps companies avoid fines and negative publicity while demonstrating a commitment to environmental sustainability.

The Environmental Benefits of Reverse Logistics

Reverse logistics plays a pivotal role in promoting sustainability and reducing waste. By diverting products from landfills and integrating them into a closed-loop supply chain, companies can lessen their environmental footprint and enhance social responsibility. This may involve recycling materials, refurbishing products, or repurposing items for alternative uses.

Another significant environmental advantage is the reduction of greenhouse gas emissions. Consolidating returned products for larger shipments decreases the number of individual shipments, thereby lowering associated emissions. Additionally, refurbishing and reselling products reduces the need for new production, conserving energy and resources.

According to a U.S. Environmental Protection Agency report, effective reverse logistics can reduce waste by up to 30%, significantly contributing to environmental conservation efforts.

How Reverse Logistics Can Save Your Business Money

Reverse logistics not only benefits the environment but also offers substantial financial advantages. By reducing waste and reusing materials, companies can lower production costs and overall expenses. Additionally, reverse logistics enables businesses to recover value from products that might otherwise be lost, such as returned merchandise or excess inventory.

Improving customer satisfaction through a seamless return process can lead to increased customer loyalty and repeat business, ultimately boosting a company's revenue. A Forbes article highlights that 70% of buying experiences are based on how customers feel they are being treated, underscoring the financial importance of customer satisfaction.

Moreover, reverse logistics provides insights into supply chain inefficiencies and product design flaws. By analyzing return reasons and excess inventory, companies can identify patterns and implement changes to prevent future issues, leading to more efficient operations and long-term cost savings.

The Role of Technology in Reverse Logistics

Technology is revolutionizing reverse logistics, making it more efficient and manageable. Automated sorting and processing systems, advanced tracking, and analytics tools are essential for handling the complexities of returns and reverse logistics. Leveraging big data and the Internet of Things (IoT) provides real-time visibility into product status, optimizing reverse logistics processes for maximum efficiency.

Advanced tracking and analytics tools enable companies to identify return patterns and trends, facilitating data-driven decisions on handling returned products—whether through refurbishing, recycling, or responsible disposal. Additionally, technology helps reduce packaging and material usage in reverse logistics, further minimizing waste.

A study by McKinsey & Company indicates that companies employing advanced technologies in reverse logistics can achieve up to a 20% reduction in operational costs.

Common Challenges in Implementing a Successful Reverse Logistics Strategy

While reverse logistics offers numerous benefits, implementing a successful program presents several challenges. These include issues with product quality or compatibility, lack of visibility into the reverse logistics process, and the high costs associated with managing returns and refurbishment.

Another significant challenge is managing multiple return channels, especially with the rise of e-commerce. Customers may return products through various channels such as in-store, online, or third-party marketplaces, creating a fragmented and disjointed process. To address this, companies need to invest in integrated technology systems that streamline return processes across all channels, providing greater visibility and control.

Additionally, ensuring compliance with varying regulatory requirements for product disposal and recycling can complicate reverse logistics operations. Companies must stay informed about relevant regulations to avoid legal issues and maintain their reputation.

Best Practices for Implementing a Reverse Logistics Program

Implementing a successful reverse logistics program requires adopting best practices and strategies that ensure efficiency and effectiveness. Key practices include:

- Continuous Improvement Initiatives: Regularly evaluate and refine reverse logistics processes to enhance performance and adaptability.

- Robust Tracking and Visibility Systems: Utilize advanced tracking systems to monitor returned products throughout the reverse logistics cycle.

- Effective Communication and Collaboration: Foster strong relationships with suppliers, partners, and logistics providers to streamline reverse logistics operations.

- Focus on Sustainability: Prioritize waste reduction and environmental responsibility in all reverse logistics activities.

Establishing clear goals and metrics, such as waste diversion rates, refurbishment success rates, and cost savings, is essential for measuring the success of reverse logistics programs. Regular monitoring and reporting of these metrics ensure continuous improvement and tangible benefits.

Investing in appropriate technology and infrastructure, including specialized software for tracking returns and equipment for refurbishing or recycling products, is crucial for supporting efficient reverse logistics operations. Partnerships with logistics providers specializing in reverse logistics can further enhance process efficiency and cost-effectiveness.

The Impact of E-commerce on the Need for Reverse Logistics

The explosive growth of e-commerce has significantly heightened the demand for effective reverse logistics. With the proliferation of online shopping and home delivery, returns and product exchanges have become integral to the retail landscape. This surge has driven the need for robust reverse logistics processes to manage the increased volume and complexity of returns while maintaining excellent customer service.

One of the primary challenges in the e-commerce era is the high volume of returns, often exacerbated by free return policies. Efficient processing, restocking, and disposal of returned products are essential to handle this influx effectively. Implementing automated return processing systems and optimizing logistics networks are critical strategies for managing high return volumes.

Sustainability concerns are also driving the need for effective reverse logistics in e-commerce. Consumers are increasingly environmentally conscious, seeking companies that prioritize sustainable practices in product delivery and return management. Demonstrating a commitment to sustainable reverse logistics can provide a competitive edge in the e-commerce market.

A report by Statista indicates that the average return rate for online purchases is approximately 20%, highlighting the critical importance of efficient reverse logistics in e-commerce.

Case Studies: Real-World Examples of Successful Reverse Logistics Implementation

Several companies have successfully implemented reverse logistics programs, reaping significant benefits in cost savings, sustainability, and customer satisfaction. Notable examples include:

- Dell: Dell has established a closed-loop recycling program, allowing customers to return used electronics for refurbishment and recycling. This initiative not only reduces e-waste but also recovers valuable materials for future use.

- IKEA: IKEA's innovative reverse logistics program utilizes recycled materials to create new products, significantly reducing waste and promoting sustainability.

- Patagonia: Patagonia's "Worn Wear" program encourages customers to repair and reuse their clothing rather than discarding it. The company also offers a trade-in program where customers can exchange used Patagonia clothing for store credit, fostering sustainability and enhancing brand loyalty.

These case studies demonstrate how effective reverse logistics can drive environmental responsibility, cost efficiency, and stronger customer relationships.

Key Performance Indicators to Measure the Success of Your Reverse Logistics Program

To effectively manage reverse logistics programs, companies must track and analyze key performance indicators (KPIs) that reflect program performance. Essential KPIs include:

- Return Rate: The percentage of products returned by customers, indicating the effectiveness of return policies and product satisfaction.

- Recovery Rate: The proportion of returned products that are successfully refurbished, recycled, or resold, reflecting the program's efficiency in value recovery.

- Cost of Returns: The total expense associated with managing returns, including transportation, processing, and refurbishment costs.

- Customer Satisfaction: Metrics such as Net Promoter Score (NPS) or customer feedback ratings related to the returns process.

By monitoring these KPIs, companies can identify areas for improvement, optimize their reverse logistics processes, and ensure they are deriving maximum value from their programs.

Regular analysis of KPIs enables continuous improvement, ensuring that reverse logistics processes remain efficient, cost-effective, and aligned with business objectives.

How to Integrate Sustainability into Your Reverse Logistics Strategy

As sustainability becomes a critical aspect of business operations, integrating it into reverse logistics strategies is essential. Companies can adopt various strategies to enhance sustainability, including:

- Product Redesign: Designing products for easier disassembly, recycling, and refurbishment to minimize waste.

- Eco-friendly Packaging: Utilizing recyclable or biodegradable packaging materials to reduce environmental impact.

- Robust Recycling Programs: Establishing comprehensive recycling and recovery programs to ensure returned products are processed responsibly.

Incorporating sustainability into reverse logistics not only enhances environmental performance but also meets the growing consumer demand for responsible business practices. Companies that prioritize sustainable reverse logistics can strengthen their market position and brand reputation.

A study by MIT Sloan reveals that companies with strong sustainability initiatives often experience higher profitability and customer loyalty.

The Future of Reverse Logistics: Predictions and Trends to Watch Out For

The future of reverse logistics is poised for significant evolution, driven by technological advancements and changing market dynamics. Key trends and predictions include:

- Advanced Tracking and Analytics: Enhanced tracking systems and data analytics will enable more precise management of reverse logistics processes, improving efficiency and decision-making.

- Circular Economy Models: Increasing adoption of circular economy principles, where products are designed for reuse, refurbishment, and recycling, will shape reverse logistics strategies.

- Automation and Robotics: Automation technologies, including robotics and AI, will streamline reverse logistics operations, reducing costs and increasing processing speed.

- Sustainable Practices: Growing emphasis on sustainability will drive innovations in reverse logistics, focusing on reducing environmental impact and promoting resource efficiency.

By staying abreast of these trends and fostering innovation within their reverse logistics strategies, companies can maintain a competitive edge and ensure long-term success in the evolving supply chain landscape.

As noted by Forbes Technology Council, companies that proactively adapt to these future trends will be better positioned to navigate the complexities of reverse logistics and leverage its full potential.