Understanding the Cost of Warehouse Automation

As businesses strive to optimize their supply chain operations, warehouse automation has become an essential tool. A fully automated warehouse can improve efficiency, reduce labor costs and errors, and enhance customer satisfaction. However, the cost of implementing automation can be significant, and it's essential to understand the factors that affect the price tag. In this article, we'll explore the importance, benefits, types, and challenges of warehouse automation. We'll also take a deep dive into the cost of automation and how to evaluate its worth, so you can determine if it's right for your business.

The Importance and Benefits of Warehouse Automation

Warehousing is a crucial link in the supply chain that stores and distributes goods to retailers, distributors, and end customers. To remain competitive, businesses must operate at peak efficiency, which requires optimized warehouse operations. Technology plays a pivotal role in enhancing efficiency, and automation is at the forefront of this transformation. According to a 2023 McKinsey report, over 70% of leading companies have integrated some form of automation into their warehousing processes.

Automating your warehouse can bring significant benefits, such as:

- Faster order processing: Automated systems can transport and sort goods faster than manual processes, speeding up order fulfillment.

- Higher order accuracy: Automated processes are more precise, improving the accuracy of order picking and reducing errors.

- Better inventory control: Automated systems track inventory levels and locations in real-time, reducing the risk of stockouts and overstocking.

- Faster returns processing: Automated processes can quickly assess returned items and route them appropriately for restocking or disposal.

Moreover, automation can enhance workplace safety by reducing the need for manual labor and minimizing the risk of accidents. It can lead to long-term cost savings, as automated systems operate continuously without the need for breaks. Additionally, automation provides real-time data and analytics, allowing businesses to make informed decisions and further optimize their operations.

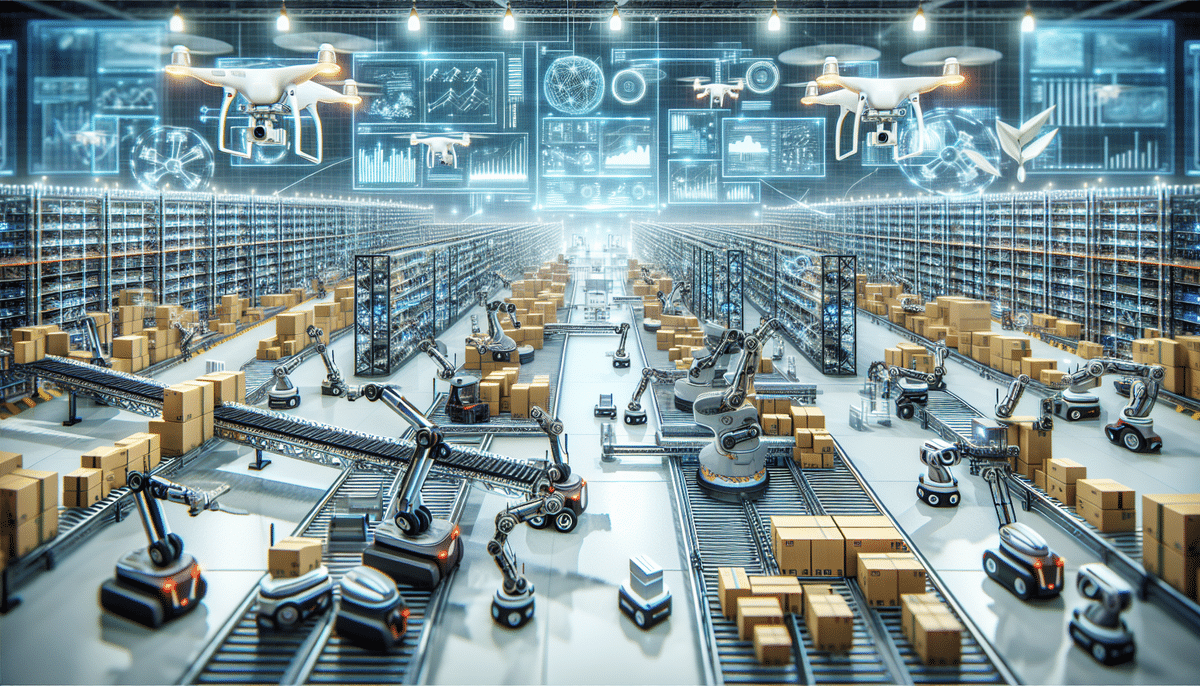

Types of Warehouse Automation Technologies

There are several types of warehouse automation technologies, each offering unique benefits:

- Automated Storage and Retrieval Systems (AS/RS): Utilize robotic cranes to move goods within the warehouse efficiently.

- Conveyor Systems: Transport goods from one location to another automatically, streamlining the movement process.

- Sortation Systems: Automatically sort and route items to designated locations, enhancing order processing speed.

- Picking Systems: Use automated robots to pick items from racks and shelves accurately.

- Shuttle Systems: Deploy automated shuttles to move goods quickly and efficiently across the warehouse.

- Robotics: Implement robots for various tasks, such as palletizing or depalletizing goods, improving operational efficiency.

Each type of automation technology has its advantages and drawbacks. It's essential to select a solution that aligns with your business goals and requirements.

One of the most significant benefits of warehouse automation technologies is the increased efficiency they provide. By automating tasks previously performed manually, businesses save time and reduce errors, leading to faster and more accurate order fulfillment.

Another advantage is the optimization of space utilization. For instance, automated storage and retrieval systems can store goods in a much smaller footprint compared to traditional shelving systems, maximizing the use of available space.

Cost Factors and ROI Analysis

Factors That Affect the Cost of Warehouse Automation

Several factors can influence the cost of warehouse automation:

- Size of the Warehouse: Larger warehouses require more automation equipment, increasing the overall cost.

- Type of Automation: Different automation technologies vary in cost, with some requiring more significant investment than others.

- Integration with Existing Systems: Integrating new automation equipment with existing systems can add to the overall expense.

- Training and Maintenance: Operating and maintaining automated equipment may necessitate additional training and support, increasing costs.

- Customization Requirements: Tailoring automation equipment to meet specific business needs can further elevate costs.

Additionally, the complexity of the automation system plays a critical role in determining costs. More complex systems may require advanced equipment and software, as well as extensive planning and implementation, all of which contribute to higher expenses. Carefully evaluating the necessary level of complexity ensures a cost-effective solution for your business.

Return on Investment (ROI)

When evaluating the cost of automation, conducting a Return on Investment (ROI) analysis is crucial to determine if the investment will pay off. An ROI analysis compares the upfront costs of automation, such as equipment and installation, against the expected savings. These savings may include reduced labor costs, increased productivity, and improved accuracy.

For example, according to a 2023 Gartner report, businesses that implemented warehouse automation saw an average ROI of 25% within the first two years. It's essential to also consider the opportunity costs of not automating your warehouse, such as missed revenue opportunities due to inefficient operations and lost customers due to poor service.

By analyzing these factors, you can determine if warehouse automation is a worthwhile investment for your business.

Evaluating the Total Cost of Ownership (TCO)

When assessing the cost of warehouse automation, it's essential to consider the Total Cost of Ownership (TCO) over the equipment's lifetime. TCO includes:

- Upfront Costs: Initial expenses for equipment purchase and installation.

- Ongoing Costs: Maintenance, repair, and upgrades required to keep the system operational.

- Operational Costs: Energy consumption and other utilities necessary for running automated systems.

- Training Costs: Expenses related to training employees to use and maintain the automated equipment.

Considering TCO is crucial for determining the Return on Investment (ROI) of warehouse automation. By evaluating both upfront and ongoing costs, businesses can make informed decisions about the long-term financial impact of automation.

Implementation Strategies and Challenges

How to Implement Warehouse Automation Successfully

Implementing warehouse automation can be a complex process. To ensure success, it's essential to follow these best practices:

- Identify Key Areas for Automation: Determine which areas of the warehouse will benefit most from automation and prioritize accordingly.

- Partner with a Trusted Vendor: Work with an automation vendor experienced in your industry who can provide customized solutions.

- Conduct a Thorough Needs Assessment: Assess your specific requirements to choose the right type of automation technology for your business.

- Develop a Detailed Implementation Plan: Outline timelines, milestones, and resources needed to guide the implementation process.

- Provide Adequate Training: Ensure employees are trained to operate and maintain automated equipment effectively.

- Monitor and Adjust: Continuously monitor the implementation progress and make necessary adjustments to address any issues.

By adhering to these steps, you can prepare for a successful warehouse automation implementation.

Key Challenges Faced During Warehouse Automation Implementation

Implementing warehouse automation presents several challenges:

- Integration with Existing Systems: Seamlessly incorporating new automation equipment with current systems can be difficult.

- Employee Training: Employees may require additional training to operate and maintain automated equipment.

- Maintenance: Automated equipment often requires more maintenance than manual processes, which can be costly and time-consuming.

- Customization: Tailoring automation equipment to meet specific business needs can be expensive and time-consuming.

Addressing these challenges early on is crucial for a successful implementation.

Future Trends and Case Studies

Future of Warehouse Automation: Trends and Predictions

The future of warehouse automation is promising, with new and improved technologies emerging regularly. Key trends and predictions include:

- Continued Adoption of Robotics and AI: Increased use of advanced robotics and artificial intelligence to enhance operational efficiency.

- Use of Drones and Autonomous Vehicles: Enhanced transportation and distribution capabilities within warehouses.

- Growth of Cloud-Based Warehouse Management Systems: Improved monitoring and control through cloud technology.

- Integration of Augmented and Virtual Reality: Enhanced training and safety measures using AR and VR technologies.

As technology advances, staying informed about emerging trends is essential to leverage their benefits and remain competitive in the industry.

Case Studies: Success Stories of Companies that Implemented Warehouse Automation

Many companies have achieved significant benefits from implementing warehouse automation:

- DHL Supply Chain: Implemented an automated storage and retrieval system, resulting in a 50% reduction in labor costs and a 70% increase in productivity. Read more.

- Medline Industries: Adopted an automated picking system, leading to a 35% reduction in labor costs and a 30% increase in productivity. Read more.

- Amazon: Utilizes a range of automation technologies, including Kiva robots, to streamline operations across its fulfillment centers. Read more.

These success stories demonstrate the tangible benefits of warehouse automation in various industries.

Common Misconceptions About Warehouse Automation

There are several misconceptions surrounding warehouse automation:

- Automation Will Replace All Human Labor: While automation reduces the need for manual tasks, it often complements human workers by handling repetitive tasks, allowing employees to focus on more complex activities.

- Automation Is Too Expensive for Small and Medium-Sized Businesses: Advances in technology have made automation more accessible and scalable, offering solutions tailored to businesses of all sizes.

- Automation Is a One-Time Investment with No Ongoing Maintenance: Automated systems require regular maintenance and updates to ensure optimal performance and longevity.

Understanding these misconceptions is vital for making informed decisions about warehouse automation.

Choosing the Right Vendor for Your Warehouse Automation Project

Selecting the appropriate vendor is critical for the success of your warehouse automation project. Consider the following when choosing a vendor:

- Industry Experience: Choose a vendor with a proven track record in your specific industry.

- Customized Solutions: Ensure the vendor can provide tailored solutions that meet your unique business needs.

- Comprehensive Support and Maintenance: Select a vendor that offers robust support and maintenance services to keep your automation systems running smoothly.

- References and Case Studies: Look for vendors who can provide references from similar projects and demonstrate successful automation implementations.

By carefully evaluating potential vendors based on these criteria, you can select a partner that will help you achieve your automation goals effectively.

Ensuring a Smooth Transition from Manual to Automated Warehousing

Transitioning from manual to automated warehousing can pose several challenges. To ensure a smooth transition, consider the following strategies:

- Effective Communication: Keep employees informed about the changes and the reasons behind automation.

- Adequate Training: Provide comprehensive training to ensure employees can operate and maintain the new automated systems effectively.

- Clear Processes and Procedures: Establish well-defined processes to guide operations during and after the transition.

- Continuous Monitoring: Regularly monitor the implementation process to identify and address any issues promptly.

By implementing these strategies, businesses can facilitate a seamless transition to automated warehousing, minimizing disruptions and maximizing the benefits of automation.

Conclusion

In conclusion, understanding the cost of warehouse automation requires a thorough analysis of its benefits, costs, and challenges. By evaluating ROI, selecting the right vendor, and planning for successful implementation, businesses can leverage automation to optimize their supply chain operations and achieve sustained growth.