Understanding the Reorder Quantity Formula

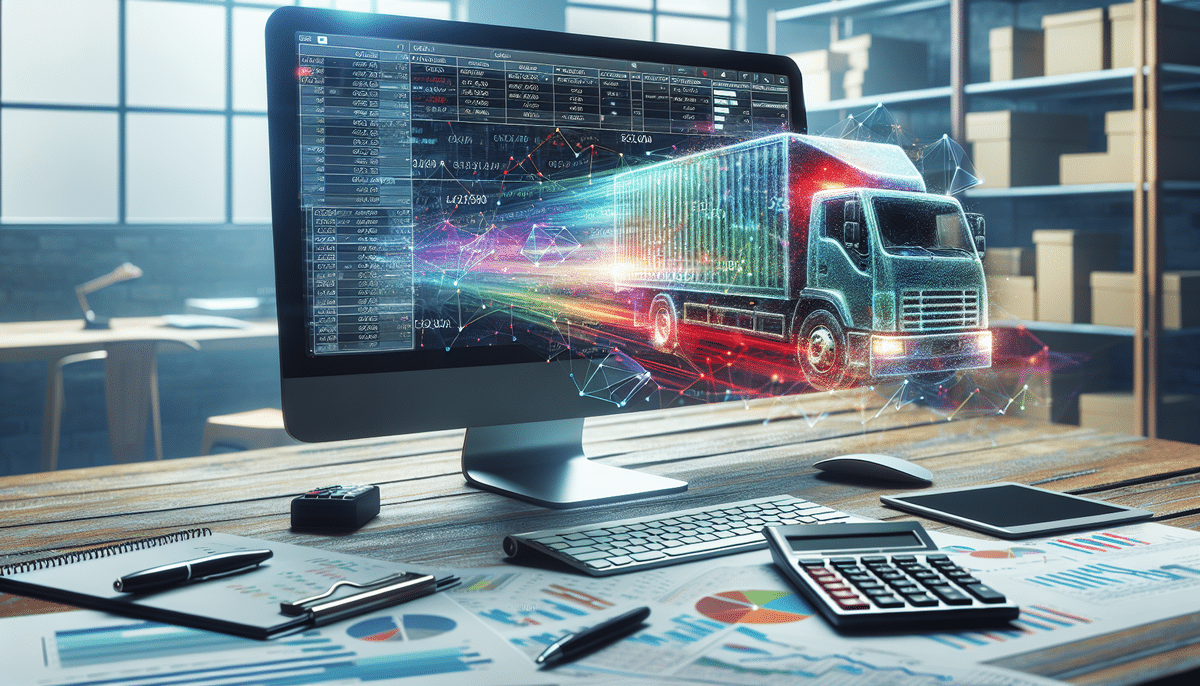

Effective inventory management is crucial for business operations, and the reorder quantity formula is a vital tool for maintaining optimal inventory levels. This article delves into the significance of the reorder quantity formula, its calculation, factors influencing it, common pitfalls, benefits, limitations, comparisons with other inventory management formulas, real-life examples, tips for efficient inventory management, future trends, and the importance of employing the right inventory management techniques, including the reorder quantity formula.

Importance of the Reorder Quantity Formula

The reorder quantity formula is essential for inventory management as it helps businesses maintain the right balance between understocking and overstocking. Overstocking ties up capital and increases holding costs, while understocking can lead to stockouts, lost sales, and reduced customer satisfaction.

- Avoids excess inventory and reduces storage costs.

- Ensures sufficient stock to meet customer demand.

- Enhances cash flow management by optimizing inventory levels.

- Improves overall operational efficiency.

According to a Supply Chain Digital report, businesses that effectively manage their reorder quantities can reduce inventory costs by up to 20%.

Calculating the Reorder Quantity Formula

Formula Components

The reorder quantity formula is expressed as:

Reorder Quantity = (Average Daily Usage x Lead Time in Days) + Safety Stock

- Average Daily Usage: The average number of units sold per day.

- Lead Time: The time it takes from placing an order to receiving the inventory.

- Safety Stock: Additional stock held to mitigate the risk of stockouts due to demand variability or supply delays.

Best Practices in Calculation

- Use accurate and up-to-date sales data to determine average daily usage.

- Consider variability in lead times and adjust safety stock accordingly.

- Regularly review and update the formula inputs to reflect changes in demand and supply conditions.

Implementing inventory management software can automate these calculations and enhance accuracy.

Factors and Considerations

Demand Forecasting

Accurate demand forecasting is critical for determining the appropriate reorder quantity. Utilizing historical sales data and market trends can improve forecast accuracy.

Lead Time

Understanding supplier lead times helps in planning reorder points effectively. Longer lead times may require larger safety stocks.

Cost of Carrying Inventory

Includes storage costs, insurance, and opportunity costs. Minimizing these costs while maintaining sufficient stock is key.

Supplier Reliability

Reliable suppliers can reduce the need for high safety stocks. Assessing supplier performance helps in making informed reorder decisions.

Seasonality

Adjust reorder quantities based on seasonal demand fluctuations to prevent stockouts during peak periods.

Benefits and Limitations

Advantages of Using the Reorder Quantity Formula

- Optimizes inventory levels, reducing holding and shortage costs.

- Enhances cash flow management by preventing over-investment in inventory.

- Improves customer satisfaction by ensuring product availability.

- Facilitates better demand forecasting and planning.

Limitations and Challenges

- Assumes constant demand and lead time, which may not always hold true.

- Relies heavily on accurate data inputs.

- Does not account for sudden market changes or disruptions.

- May require frequent adjustments to remain effective.

According to Investopedia, the reorder quantity formula may not be suitable for businesses with highly variable demand patterns.

Common Mistakes to Avoid

- Using outdated or inaccurate data for calculations.

- Incorrectly estimating safety stock levels.

- Ignoring lead time variability.

- Failing to account for seasonal demand changes.

- Not regularly reviewing and updating the reorder formula inputs.

A study by Harvard Business Review highlights that businesses often overlook the importance of adjusting reorder quantities based on real-time data, leading to inefficiencies.

Comparing Inventory Management Formulas

Economic Order Quantity (EOQ)

EOQ aims to determine the optimal order quantity that minimizes the total inventory costs, including ordering and holding costs.

Just-In-Time (JIT)

JIT focuses on reducing inventory levels by receiving goods only as they are needed in the production process.

Material Requirements Planning (MRP)

MRP is a system for calculating the materials and components needed to manufacture a product, ensuring that inventory levels are maintained efficiently.

While the reorder quantity formula is simpler compared to EOQ and MRP, it is less flexible than JIT, which requires precise demand forecasting and supplier coordination.

Real-life Case Studies

Automotive Industry: Toyota

Toyota implemented the reorder quantity formula as part of its lean manufacturing system, reducing inventory levels by 50% and significantly cutting costs.

Fast Food Industry: McDonald's

McDonald's uses the reorder quantity formula to optimize inventory levels for its restaurants worldwide, improving customer service and increasing sales.

Retail Industry: Walmart

Walmart utilizes advanced inventory management techniques, including the reorder quantity formula, to streamline its inventory systems, reduce stockouts, and enhance customer satisfaction.

For instance, Walmart's effective inventory management has been reported to contribute to the company's ability to offer low prices and maintain high product availability (Forbes).

Healthcare Industry

Hospitals and clinics apply the reorder quantity formula to manage medical supplies, ensuring sufficient stock to meet patient needs while minimizing waste and reducing costs.

Tips for Efficient Inventory Management

- Regularly update sales and inventory data to maintain accurate calculations.

- Utilize inventory management software to automate reorder processes.

- Set appropriate reorder points based on lead time and demand variability.

- Monitor inventory levels consistently to identify trends and adjust accordingly.

- Collaborate closely with suppliers to improve lead time reliability.

Incorporating these tips can enhance the effectiveness of the reorder quantity formula and overall inventory management strategy.

Future Trends in Inventory Management

The future of inventory management is set to be influenced by technologies such as automation, data analytics, artificial intelligence (AI), and machine learning (ML). These advancements will enhance the accuracy of reorder quantity calculations and allow for more dynamic inventory management.

- Automation: Streamlines the inventory ordering process, reducing manual errors.

- Data Analytics: Provides deeper insights into sales patterns and demand forecasting.

- AI and ML: Enables predictive modeling and real-time adjustments to inventory levels based on changing market conditions.

According to a report by McKinsey & Company, organizations leveraging AI and ML can achieve up to a 20% improvement in inventory accuracy and a 15% reduction in inventory costs.

Conclusion: The Importance of Using the Right Inventory Management Techniques

Inventory management is a critical facet of business operations, and the reorder quantity formula serves as a powerful tool for maintaining optimal inventory levels. By utilizing this formula, businesses can prevent overstocking and understocking, minimize inventory-related costs, and enhance customer satisfaction. As competition intensifies and the demand for efficiency grows, employing effective inventory management techniques, including the reorder quantity formula, becomes increasingly vital.

Furthermore, leveraging advanced technologies can augment the effectiveness of inventory management practices, allowing businesses to adapt swiftly to market changes and customer demands. Prioritizing accurate data, strategic planning, and continuous improvement in inventory management processes ensures that businesses can maintain a competitive edge and achieve sustained growth.