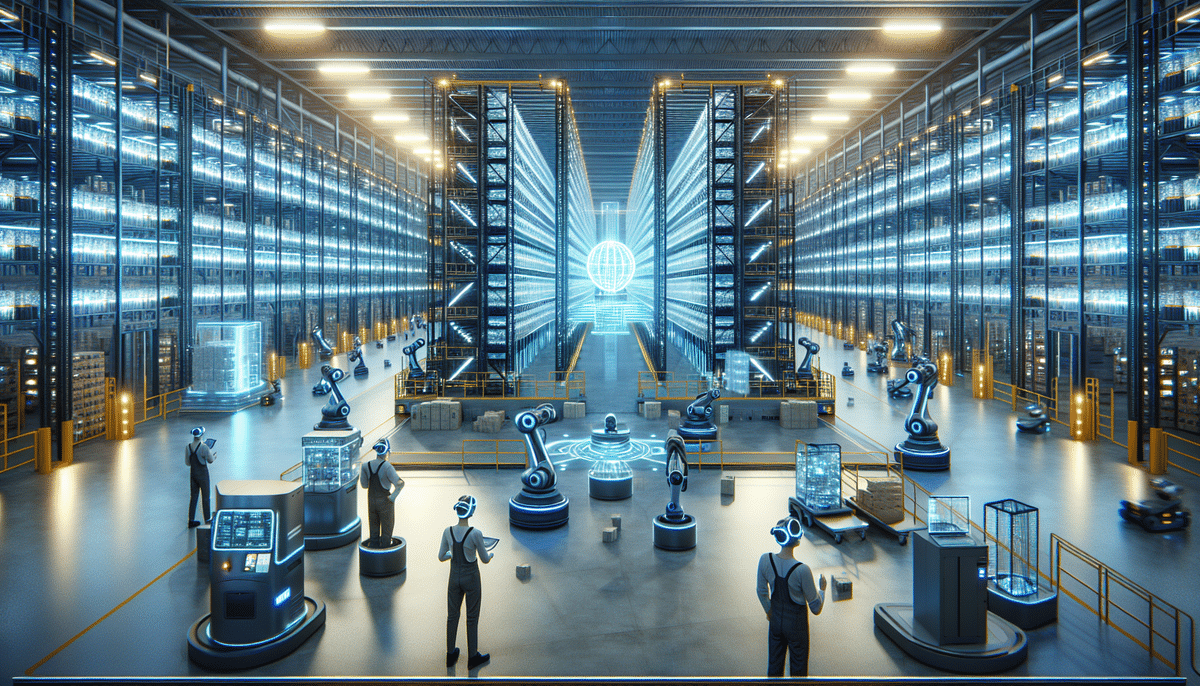

Introduction to Advanced Warehouse Automation

In today's fast-paced world of logistics and e-commerce, the need for advanced warehouse automation technology is greater than ever before. The pressure to deliver products faster, more cost-effectively, and with greater accuracy can only be met by leveraging the latest developments in automation. This article explores how advanced technologies such as robotics, artificial intelligence (AI), and automated storage and retrieval systems (ASRS) are revolutionizing warehouse operations, leading to faster turnaround times, higher efficiency, and improved customer service.

Key Technologies Driving Warehouse Automation

Robotics in Warehouse Automation

The use of robots in warehouses has surged in recent years, with companies leveraging robotics to streamline everything from inventory management to order fulfillment. According to a report by McKinsey & Company, the adoption of robotics can increase warehouse productivity by up to 30%.

Robotic systems offer several advantages:

- Continuous Operation: Robots work without breaks, leading to higher productivity.

- Collaboration with Humans: Robots handle repetitive and physically demanding tasks, reducing strain on human workers.

- Data Collection and Analysis: Equipped with sensors, robots gather data on inventory levels and warehouse conditions, enabling optimization of layouts and processes.

- Enhanced Safety: Robots manage hazardous tasks, minimizing the risk of injury to workers.

Artificial Intelligence in Warehouse Operations

Artificial intelligence (AI) is a transformative technology reshaping warehouse automation. Leveraging machine learning algorithms and predictive analytics, AI-powered systems optimize operations by forecasting consumer demand, managing inventory levels, and minimizing human error.

Key benefits of AI in warehouses include:

- Optimized Routing and Scheduling: AI improves the efficiency of resource use and reduces fulfillment times.

- Enhanced Safety: AI systems detect potential hazards, alerting workers to prevent accidents.

- Quality Control: AI identifies product defects, ensuring only high-quality items are shipped.

According to Forbes, AI can improve order accuracy by up to 50% and reduce fulfillment times by 20%.

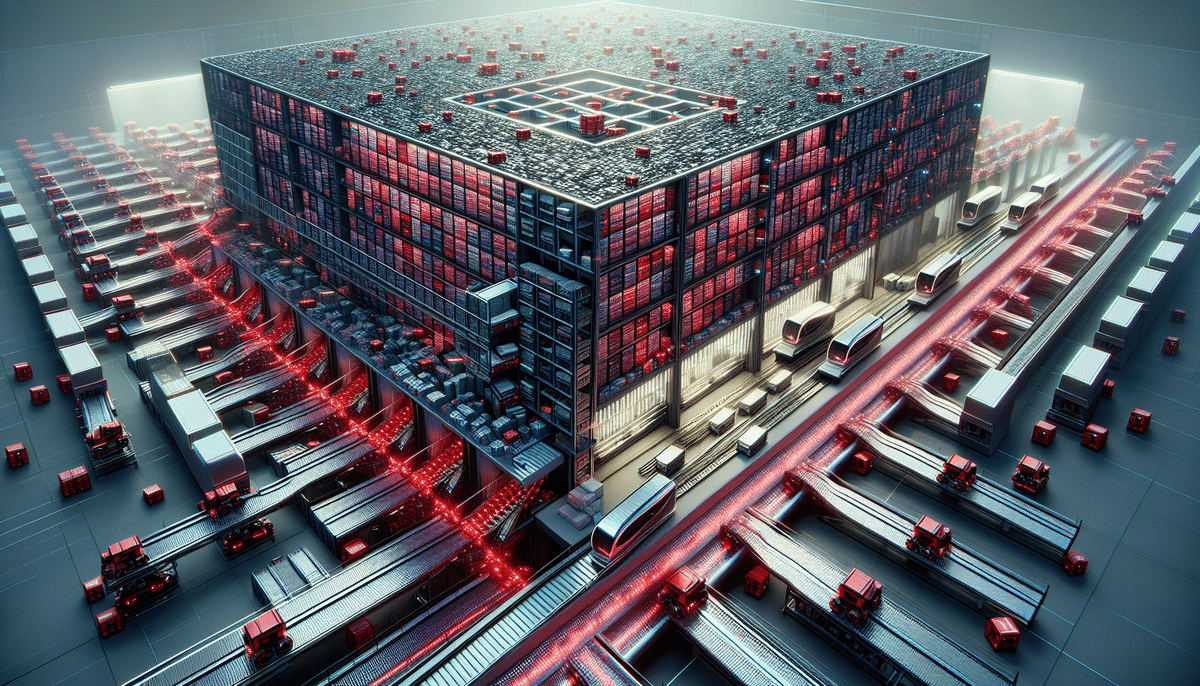

Automated Storage and Retrieval Systems (ASRS)

Automated storage and retrieval systems (ASRS) are designed to optimize product storage and retrieval, enabling warehouses to operate with greater efficiency and accuracy. These systems use advanced robotics and conveyor belts to transport products with minimal human intervention.

Benefits of ASRS include:

- Maximized Storage Space: Utilizing vertical space and compact configurations allows more products to be stored in a smaller area.

- Improved Inventory Accuracy: Automated tracking ensures products are accurately accounted for and easily located.

Automated Picking and Packing Systems

Automated picking and packing systems integrate robotics and AI to enable the picking and packing of products with unprecedented speed and accuracy.

Advantages include:

- Faster Order Fulfillment: Automated systems can reduce fulfillment time by up to 40%, according to Statista.

- Diverse Product Handling: Capable of managing items of various shapes, sizes, and weights.

- Minimized Errors: Ensures accurate picking and packing, enhancing customer satisfaction.

Integration with Warehouse Management Systems (WMS)

The integration of warehouse management systems (WMS) with automation technology is critical for maximizing the benefits of warehouse automation. WMS software effectively manages inventory levels, tracks product movements, and streamlines communication between various warehouse components.

Key benefits include:

- Increased Efficiency: Enhanced coordination between automated systems and WMS leads to faster turnaround times.

- Improved Safety: Automated systems handle heavy lifting, reducing injury risks for workers.

- Real-Time Monitoring: WMS provides real-time data, aiding in decision-making and operational optimization.

Cloud-Based WMS Advantages

Cloud-based warehouse management systems (WMS) offer scalability, flexibility, and cost-effectiveness, allowing companies to adapt to changing business needs seamlessly.

Advantages of cloud-based WMS include:

- Scalability: Easily adjust to fluctuating inventory levels and business growth.

- Real-Time Visibility: Enhanced visibility into warehouse operations for better decision-making.

- Seamless Integration: Easy integration with other automated systems and real-time updates.

- Robust Security: Advanced security features and automatic updates ensure data protection.

Implementing Warehouse Automation

Choosing the Right Automation Technology

Selecting the appropriate automation technology for your warehouse is crucial for achieving desired operational results. Consider factors such as warehouse size, product volume, and budget when evaluating technology solutions.

Important considerations include:

- Customization: Choose solutions that offer the flexibility to adapt to specific warehouse layouts and processes.

- Scalability: Ensure the technology can grow with your business needs.

- Integration: Opt for technologies that seamlessly integrate with existing systems like WMS.

Consulting with experienced automation providers can guide companies through the selection process, ensuring the chosen technology aligns with specific operational requirements.

Overcoming Implementation Challenges

Implementing warehouse automation technology can be complex, with challenges such as worker resistance, technical complexity, and cost overruns.

Strategies to overcome these challenges include:

- Effective Change Management: Clear communication of automation benefits and providing adequate training can mitigate worker resistance.

- Partnering with Experts: Collaborate with experienced automation providers to navigate technical complexities.

- Budget Planning: Develop a comprehensive budget that accounts for both upfront and ongoing costs to prevent overruns.

Safety Measures in Automation

Implementing advanced warehouse automation technology necessitates a strong focus on safety and risk management.

Essential safety measures include:

- Comprehensive Training: Ensure all workers are trained in the use of automation technology.

- Safety Protocols: Establish protocols to prevent accidents, such as emergency stop mechanisms and barrier sensors.

- Regular Maintenance: Conduct routine inspections and maintenance of automation equipment to ensure safe operation.

- Automated Safety Features: Integrate features like automated alerts to enhance workplace safety.

Creating a culture of safety and continuous improvement ensures that the benefits of automation do not compromise employee well-being.

Business Benefits of Warehouse Automation

Cost Savings and ROI

While investing in advanced warehouse automation technology involves significant upfront costs, the long-term cost savings and return on investment (ROI) can be substantial.

Benefits include:

- Reduced Labor Costs: Automation decreases the need for manual labor, lowering payroll expenses.

- Higher Productivity: Increased efficiency leads to more output without proportional increases in costs.

- Improved Accuracy: Minimizing errors reduces costs associated with returns and replacements.

According to a study by Savioke, companies can expect an ROI within two years of implementing warehouse automation solutions, with ongoing savings enhancing profitability.

Increased Efficiency and Accuracy

Automation enhances warehouse efficiency by streamlining operations and reducing manual interventions.

- Faster Order Fulfillment: Automated systems process orders more quickly than manual methods.

- Enhanced Inventory Management: Real-time tracking and automated replenishment increase inventory accuracy.

- Space Optimization: Efficient use of warehouse space allows for more storage without expansion.

Enhanced Customer Satisfaction

By improving accuracy and speed, warehouse automation directly impacts customer satisfaction.

Key factors include:

- Timely Deliveries: Faster fulfillment times ensure orders reach customers promptly.

- Accurate Orders: Reduced errors lead to correct deliveries, minimizing returns and complaints.

- Consistent Quality: Automation maintains high standards in order processing, enhancing overall customer experience.

Case Studies: Successful Automation Implementations

Numerous companies have successfully implemented advanced warehouse automation technology to achieve significant business benefits. Industry leaders like Amazon, DHL, and Walmart have invested heavily in robotics, AI, and other advanced technologies, resulting in higher productivity, lower costs, and improved customer satisfaction.

For example, Amazon's use of Kiva robots in their fulfillment centers has reduced the time taken to locate and retrieve products by 50%, significantly speeding up order fulfillment. Similarly, DHL has integrated AI and robotics to optimize their sorting and packing processes, leading to enhanced efficiency and accuracy.

Learning from these success stories can help other businesses achieve similar outcomes by adopting best practices and leveraging proven technologies.

Future Trends in Warehouse Automation Technology

The future of warehouse automation technology is promising, with continuous innovations in robotics, AI, and machine learning poised to further revolutionize warehouse operations.

Emerging trends include:

- Autonomous Mobile Robots (AMRs): AMRs are being developed to navigate warehouses more efficiently, enhancing mobility and flexibility.

- Drones: Utilized for inventory management and surveillance, drones offer quick and accurate stocktaking capabilities.

- Augmented Reality (AR): AR assists workers in locating items and managing orders with enhanced precision and speed.

- Internet of Things (IoT): IoT devices enable real-time monitoring and data collection, further optimizing warehouse operations.

Staying ahead of these trends and integrating emerging technologies can provide warehouses with competitive advantages, enhancing operational efficiency and adaptability to evolving market demands.

Conclusion

Advanced warehouse automation technology presents a unique solution to the challenges of modern logistics and the evolving e-commerce landscape. By leveraging technologies like robotics, AI, and ASRS, companies can streamline operations, reduce costs, and enhance customer service. However, implementing these technologies requires careful planning, stakeholder engagement, and a focus on safety and risk management. By adopting a strategic approach to warehouse automation, companies can unlock significant benefits and position themselves for long-term success and growth.