Unlocking the Benefits of Vendor-Managed Inventory (VMI)

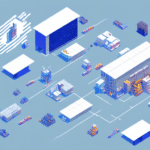

Vendor-Managed Inventory (VMI) is a supply chain management strategy that empowers suppliers to oversee and manage their customers' inventory levels. By taking control of the inventory replenishment process, vendors can ensure that customers maintain optimal stock levels, preventing both stockouts and excess inventory. In this comprehensive guide, we delve into the concept of VMI, its benefits, challenges, best practices, case studies of successful implementations, and future trends shaping the evolution of VMI.

Understanding the Concept of Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory is a collaborative business model between suppliers and customers where the supplier assumes responsibility for managing inventory levels. The supplier utilizes data provided by the customer, such as sales forecasts and current inventory levels, to determine optimal stocking quantities. This proactive approach ensures that the customer maintains the right amount of stock to meet demand without overstocking.

Key aspects of VMI include:

- Data Sharing: Customers provide suppliers with real-time data on sales, inventory levels, and demand forecasts.

- Inventory Optimization: Suppliers use this data to optimize inventory levels, reducing excess stock and minimizing stockouts.

- Automated Replenishment: Suppliers automatically replenish inventory based on predefined thresholds and demand signals.

By fostering a strategic partnership, VMI enhances supply chain efficiency and responsiveness.

The Role of VMI in Supply Chain Management

VMI plays a pivotal role in modern supply chain management by ensuring that the right products are available at the right time, thereby reducing the risk of stockouts and excess inventory. According to a report by ShipScience, companies implementing VMI have observed a 20% reduction in inventory costs and a 15% improvement in order fulfillment rates.

Benefits of VMI in supply chain management include:

- Enhanced Demand Forecasting: More accurate predictions lead to better inventory planning.

- Improved Supply Chain Visibility: Real-time data sharing enhances transparency and decision-making.

- Reduced Lead Times: Streamlined replenishment processes accelerate product availability.

- Increased Flexibility: The supply chain can quickly adapt to changes in demand patterns.

Additionally, VMI fosters stronger communication and collaboration between suppliers and customers, leading to a more resilient and efficient supply chain.

Benefits of Implementing VMI for Your Business

Implementing Vendor-Managed Inventory offers numerous advantages, including:

- Better Inventory Control and Optimization: Suppliers manage inventory levels to match actual demand.

- Improved Demand Forecasting Accuracy: Enhanced data analytics lead to more precise predictions.

- Reduced Inventory Carrying Costs: Lower storage and handling expenses due to optimized stock levels.

- Minimized Stockouts: Consistent stock levels prevent lost sales and boost customer satisfaction.

- Less Risk of Dead Stock: Reduced excess inventory minimizes waste and obsolescence.

- Enhanced Customer Service Levels: Reliable product availability enhances the customer experience.

- Shortened Lead Times: Faster replenishment cycles improve overall supply chain responsiveness.

Moreover, VMI strengthens supplier relationships by fostering mutual trust and collaboration, leading to a more integrated and efficient supply chain.

For more detailed insights, refer to ShipScience's VMI benefits report.

How VMI Helps in Reducing Inventory Costs

One of the foremost advantages of Vendor-Managed Inventory is the significant reduction in inventory carrying costs. By delegating inventory management to the supplier, businesses can:

- Avoid Overstocking: Suppliers maintain optimal stock levels based on accurate demand forecasts.

- Reduce Storage Costs: Lower inventory volumes decrease space and handling requirements.

- Minimize Waste: Preventing excess inventory reduces the risk of obsolescence and waste.

Additionally, VMI decreases costs associated with stockouts. Suppliers proactively replenish inventory, ensuring that products are always available, thereby avoiding the expenses related to emergency orders and expedited shipping.

According to industry statistics, businesses utilizing VMI have seen up to a 25% reduction in overall inventory costs.

Improving Inventory Accuracy through VMI

Inventory accuracy is crucial for effective supply chain management. VMI enhances accuracy by enabling suppliers to:

- Utilize Advanced Monitoring Systems: Real-time tracking ensures precise inventory levels.

- Implement Automated Replenishment: Reduces human error in ordering processes.

- Leverage Data Analytics: Analyzing sales and demand data leads to more accurate inventory decisions.

High inventory accuracy results in fewer discrepancies, improved order fulfillment rates, and higher customer satisfaction. Moreover, businesses can reduce the costs associated with inventory discrepancies, such as write-offs and administrative expenses.

Research by ShipScience indicates that companies with VMI systems experience a 30% improvement in inventory accuracy.

Streamlining Supply Chain Processes with VMI

VMI streamlines supply chain processes by delegating inventory management tasks to suppliers, allowing businesses to focus on core activities like sales and marketing. Key benefits include:

- Efficient Replenishment: Automated processes ensure timely restocking.

- Optimized Supply Chain Activities: Coordinated efforts reduce redundancy and improve efficiency.

- Cost Reduction: Lower inventory and shipping costs through optimized logistics.

By integrating VMI, businesses can achieve a more agile and responsive supply chain, capable of adapting to market fluctuations and consumer demands swiftly.

Enhancing Customer Service with VMI

VMI plays a crucial role in elevating customer service by ensuring consistent product availability and timely deliveries. Benefits include:

- Reliable Product Availability: Customers receive products when needed, avoiding delays.

- Improved Order Fulfillment: High inventory accuracy leads to fewer errors in orders.

- Increased Customer Satisfaction: Dependable service fosters loyalty and repeat business.

Enhanced customer service through VMI can lead to higher retention rates and positive word-of-mouth, contributing to sustained business growth.

Challenges and Risks Associated with VMI Implementation

While VMI offers numerous benefits, its implementation comes with challenges and risks that businesses must address:

- Strong Vendor-Customer Relationship: Successful VMI relies on trust and open communication. Any breakdown can disrupt the inventory management process.

- Initial Setup Costs: Implementing VMI systems may require significant investment in technology and training.

- Data Security: Sharing sensitive inventory and sales data increases the risk of data breaches.

- Dependence on Supplier Performance: The effectiveness of VMI depends on the supplier's ability to manage inventory accurately and efficiently.

To mitigate these risks, businesses should conduct thorough vendor evaluations, establish clear contractual agreements, and invest in robust cybersecurity measures.

Choosing the Right Vendors for Your VMI Program

Selecting the appropriate vendor is critical to the success of a VMI program. Consider the following factors:

- Industry Expertise: Vendors with deep knowledge of your industry can better anticipate and respond to your inventory needs.

- Technological Capabilities: Ensure the vendor has advanced inventory management systems and can integrate seamlessly with your existing technologies.

- Communication Skills: Effective and transparent communication is essential for collaborating on inventory decisions.

- Reliability and Track Record: Choose vendors with a proven history of successful VMI implementations.

For additional guidance, refer to ShipScience's vendor selection checklist.

Best Practices for Successful VMI Implementation

To maximize the benefits of VMI, adhere to the following best practices:

- Select a Compatible Vendor: Ensure alignment in goals, values, and technological capabilities.

- Define Clear Expectations: Establish specific inventory levels, replenishment schedules, and performance metrics.

- Foster Transparent Communication: Maintain open channels for regular updates and feedback.

- Invest in Training: Provide comprehensive training for both vendor and internal teams to ensure smooth operations.

- Monitor Performance: Regularly review key performance indicators (KPIs) to assess the effectiveness of the VMI program.

Implementing these strategies can help navigate potential challenges and ensure a seamless VMI integration.

Measuring the Success of Your VMI Program

Evaluating the performance of your VMI program is essential for continuous improvement. Key metrics to consider include:

- Inventory Turnover Rate: Measures how frequently inventory is sold and replaced.

- Stockout Frequency: Tracks the occurrences of stockouts over a specific period.

- Order Fulfillment Accuracy: Assesses the accuracy of orders delivered to customers.

- Lead Time Reduction: Evaluates the decrease in time from order placement to delivery.

- Return on Investment (ROI): Calculates the financial benefits relative to the costs of implementing VMI.

Regularly analyzing these metrics allows businesses to identify areas for improvement and optimize their VMI processes. For a detailed framework, consult ShipScience's VMI success measurement guide.

Case Studies: Successful Implementation of VMI in Different Industries

VMI has been successfully adopted across various industries, demonstrating its versatility and effectiveness:

- Automotive Industry: A leading automotive manufacturer implemented VMI, resulting in a 30% reduction in inventory levels and a 20% decrease in carrying costs.

- Retail Sector: A major retailer utilized VMI to optimize stock levels, achieving a 25% improvement in stock availability and enhancing customer satisfaction.

- Healthcare: A healthcare provider adopted VMI for medical supplies, reducing stockouts by 40% and ensuring timely availability of critical items.

These case studies highlight the tangible benefits of VMI, including cost savings, improved inventory accuracy, and enhanced customer service. For more detailed examples, visit ShipScience's VMI case study repository.

Future Trends and Developments in Vendor-Managed Inventory (VMI)

The landscape of Vendor-Managed Inventory is evolving, driven by technological advancements and changing market dynamics. Key future trends include:

- Artificial Intelligence and Machine Learning: AI-driven analytics enhance demand forecasting and inventory optimization, enabling more accurate and efficient VMI practices.

- Internet of Things (IoT): IoT devices provide real-time data on inventory levels, automating replenishment and reducing manual interventions.

- Cloud-Based Solutions: Cloud technologies offer greater scalability and flexibility, facilitating seamless integration between suppliers and customers.

- Blockchain Technology: Enhances transparency and traceability in the supply chain, ensuring data integrity and security.

These innovations will continue to refine VMI, making it an even more integral component of strategic supply chain management. To stay ahead, businesses should invest in emerging technologies and adapt their VMI strategies accordingly.

Conclusion: Is Vendor-Managed Inventory (VMI) Right for Your Business?

Vendor-Managed Inventory is a proven supply chain strategy that offers substantial benefits, including reduced inventory costs, improved demand forecasting, and streamlined supply chain processes. Despite the challenges associated with its implementation, such as the need for strong vendor relationships and initial setup costs, the advantages often outweigh the drawbacks.

Businesses considering VMI should:

- Evaluate Vendor Compatibility: Choose vendors aligned with your business goals and capable of supporting your VMI needs.

- Establish Clear Communication: Maintain open and transparent communication channels to facilitate effective collaboration.

- Invest in Technology: Implement robust inventory management systems to support seamless VMI operations.

- Monitor and Adjust: Continuously assess VMI performance and make necessary adjustments to optimize outcomes.

Ultimately, Vendor-Managed Inventory can be a transformative strategy for businesses seeking to enhance their supply chain efficiency and customer satisfaction. By carefully selecting the right partners and adhering to best practices, your business can harness the full potential of VMI to drive growth and competitiveness.