UPS Releases Updated Guidelines for Shipping Lithium Batteries

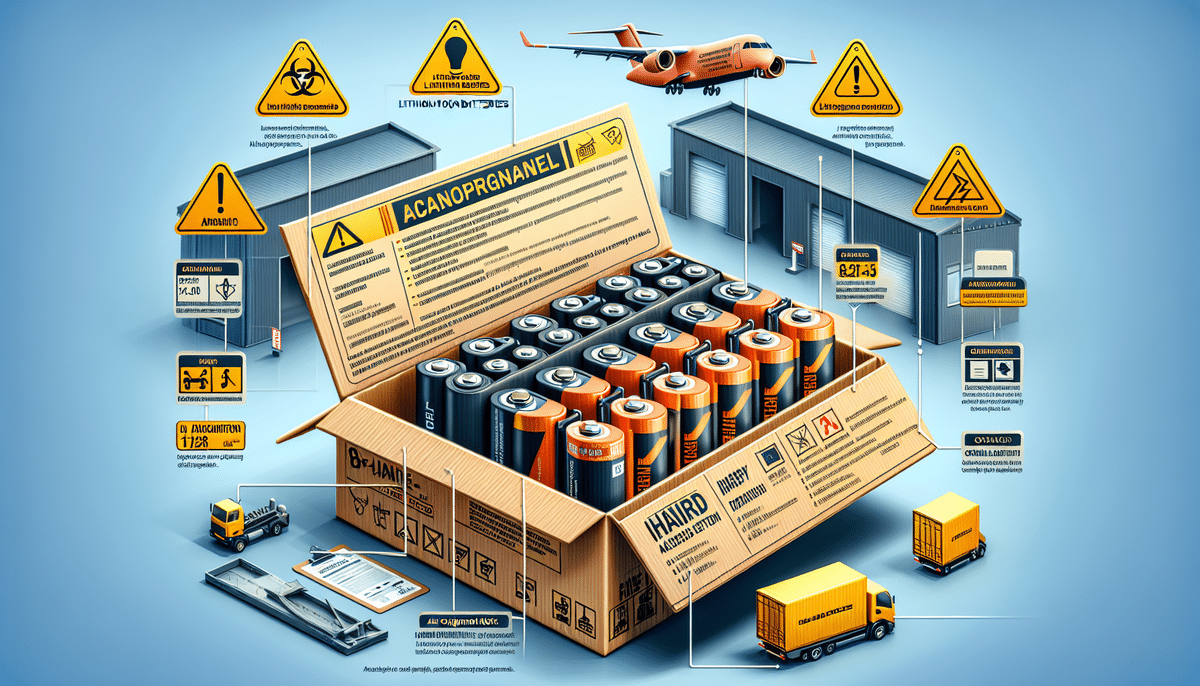

UPS, a leading global package delivery company, has introduced revised guidelines to ensure the safe transportation of lithium batteries. Lithium batteries power a wide range of electronic devices, including smartphones, laptops, and medical equipment, making them integral across various industries from consumer electronics to aerospace. However, the inherent risks associated with lithium batteries necessitate stringent shipping protocols to prevent accidents and ensure safety throughout the supply chain.

The Hazards of Shipping Lithium Batteries

Why Lithium Batteries Pose a Shipping Risk

Lithium batteries are classified as hazardous materials due to their flammable electrolytes, which can lead to fires or explosions if the batteries are damaged, short-circuited, overheated, overcharged, or exposed to moisture. The risk heightens when large quantities are shipped or when batteries are combined with incompatible materials such as metals or water. Incidents involving lithium batteries can result in severe consequences, including property damage, environmental harm, and loss of life.

According to the U.S. Department of Transportation, lithium battery-related incidents have been on the rise, emphasizing the need for strict adherence to safety protocols during shipping.

Types of Lithium Batteries and Their Risks

There are primarily two types of lithium batteries: lithium-ion and lithium metal. Lithium-ion batteries, commonly found in consumer electronics, are generally considered safer for transportation when properly packaged and labeled. In contrast, lithium metal batteries, used in certain medical and military applications, are more hazardous and require specialized handling and packaging to mitigate risks.

Regulatory Framework for Lithium Battery Shipping

International and National Regulations

Shipping lithium batteries is governed by comprehensive national and international regulations to ensure safety across all modes of transportation—air, sea, road, and rail. Organizations such as the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO) have established detailed guidelines that specify the types of batteries permitted for shipment, quantity limits, packaging standards, labeling requirements, and necessary documentation.

Compliance with these regulations is mandatory, as non-compliance can lead to substantial fines, legal repercussions, and the suspension of shipping privileges. The Environmental Protection Agency (EPA) also outlines disposal and recycling protocols to minimize environmental impact.

Training and Certification Requirements

Handlers and carriers involved in the transportation of lithium batteries must undergo specific training and certification to ensure they are well-versed in the safety measures and regulatory requirements. This training covers proper packaging techniques, emergency response procedures, and accurate documentation practices, which are crucial for maintaining safety standards and regulatory compliance.

Best Practices for Packaging and Labeling Lithium Batteries

Proper Packaging Materials

UPS recommends using UN-certified packaging materials specifically designed for lithium batteries, such as fiberboard boxes, plastic containers, or metal drums. These packages should be sturdy, leak-proof, and capable of withstanding rough handling and shocks during transit.

Additional safeguards include using specialized foam inserts and shock-absorbing coatings to protect the batteries from impact and vibration. Implementing these measures significantly reduces the risk of battery damage and potential hazards.

Accurate Labeling and Documentation

All packages containing lithium batteries must display appropriate hazard labels and markings. These labels should clearly indicate the type and quantity of batteries, along with the shipper’s and consignee’s contact information. Accurate documentation, including the air waybill and dangerous goods declaration, is essential for regulatory compliance and safe transportation.

For detailed labeling requirements, refer to the IATA Dangerous Goods Regulations.

Common Mistakes in Shipping Lithium Batteries

Overpacking and Inadequate Cushioning

One prevalent mistake is packing too many batteries in a single package without sufficient cushioning and insulation. Overpacking increases the risk of battery damage and short-circuiting, while inadequate cushioning fails to protect the batteries from impacts during transit.

Non-Compliant Packaging and Labeling

Using non-certified packaging materials and improper labeling can lead to regulatory violations and heightened safety risks. Each package must comply with international and national standards to ensure safe handling and transportation.

Lack of Proper Training

Employees who are not adequately trained in handling hazardous materials may inadvertently contribute to shipping errors. Comprehensive training programs are essential to equip staff with the necessary knowledge and skills to manage lithium battery shipments safely.

Environmental Impact of Improper Disposal of Lithium Batteries

Consequences of Improper Disposal

Discarding lithium batteries in landfills or incinerators can lead to severe environmental contamination. Batteries contain toxic chemicals and heavy metals such as lead, cadmium, and mercury, which can leach into soil and water sources, posing significant health risks to ecosystems and human populations.

Furthermore, improperly discarded batteries can release greenhouse gases, exacerbating climate change. The EPA estimates that only about 5% of lithium batteries are currently recycled, highlighting the urgent need for improved recycling efforts.

Promoting Recycling and Responsible Disposal

Recycling lithium batteries not only mitigates environmental impact but also conserves natural resources by reducing the demand for new materials. Governments and organizations worldwide are implementing policies and initiatives to encourage the responsible disposal and recycling of lithium batteries, aiming to increase recycling rates and minimize hazardous waste.

Industry Efforts and Innovations in Lithium Battery Shipping

Collaborative Standards Development

Global organizations like IATA and ICAO collaborate with battery manufacturers, shippers, and regulators to develop harmonized standards for the safe transportation of lithium batteries. These collaborative efforts focus on enhancing packaging, labeling, and handling protocols to prevent accidents and improve overall safety.

For more information on industry standards, visit the IATA Dangerous Goods Regulations.

Technological Advancements

Innovations in battery technology, such as the development of solid-state batteries, aim to reduce the risks associated with transportation by minimizing overheating and flammability. Additionally, advanced battery management systems are being designed to monitor battery health and prevent potential safety issues proactively.

Packaging innovations, including smart packaging solutions that can detect and respond to battery-related incidents, are also being explored to enhance shipping safety.

UPS’s Commitment to Innovation and Safety

UPS continues to invest in technologies and solutions that address the challenges of lithium battery transportation. Initiatives such as utilizing drones for delivering packages to remote areas and developing smart lockers for secure battery storage exemplify UPS’s dedication to innovation and safety.

By partnering with industry leaders to develop robust packaging materials and advanced handling techniques, UPS is setting new standards for the safe and efficient shipping of lithium batteries, while also promoting sustainability within the logistics sector.

Conclusion

The safe shipment of lithium batteries is a critical aspect of modern logistics, given their widespread use and associated risks. UPS’s updated guidelines provide a comprehensive framework for shippers and carriers to navigate the complex regulations and implement best practices for lithium battery transportation. Adhering to these guidelines not only ensures regulatory compliance but also safeguards people, property, and the environment from the potential hazards of lithium batteries.