Importance of Temperature Control in Shipping

Shipping temperature-sensitive items is crucial for maintaining their quality and safety. Items requiring specific temperature ranges, such as pharmaceuticals, fresh produce, and certain chemicals, must be transported under controlled conditions to prevent spoilage and ensure usability. According to the U.S. Food and Drug Administration (FDA), improper temperature management can lead to significant degradation of pharmaceutical products, posing risks to patient health.

Types of Temperature-Sensitive Items

Pharmaceuticals and Medical Supplies

Medical supplies, including vaccines, blood samples, and certain medications, require precise temperature control to maintain their efficacy. Exposure to temperatures outside the recommended range can reduce their potency, rendering them ineffective or harmful.

Food Products

Perishable food items such as fresh produce, dairy products, meat, poultry, and seafood must be kept within specific temperature ranges to prevent spoilage and inhibit the growth of harmful bacteria. The U.S. Department of Agriculture (USDA) emphasizes the importance of maintaining the cold chain to ensure food safety.

Chemicals and Laboratory Samples

Certain chemicals and laboratory samples require stable temperature conditions to preserve their stability and accuracy. Fluctuations in temperature can compromise the integrity of these substances, affecting research outcomes and safety.

Consequences of Improper Shipping

Failing to maintain appropriate temperature conditions during shipping can lead to:

- Financial Losses: Damaged or spoiled goods result in direct financial losses and potential recalls.

- Health Risks: Compromised pharmaceuticals and food products can pose serious health risks to consumers.

- Reputational Damage: Companies may suffer reputational harm due to the distribution of ineffective or unsafe products.

- Legal Liabilities: Non-compliance with regulatory standards can lead to lawsuits and fines.

For example, the World Health Organization (WHO) highlights the critical nature of maintaining the cold chain for vaccine distribution to ensure public health safety.

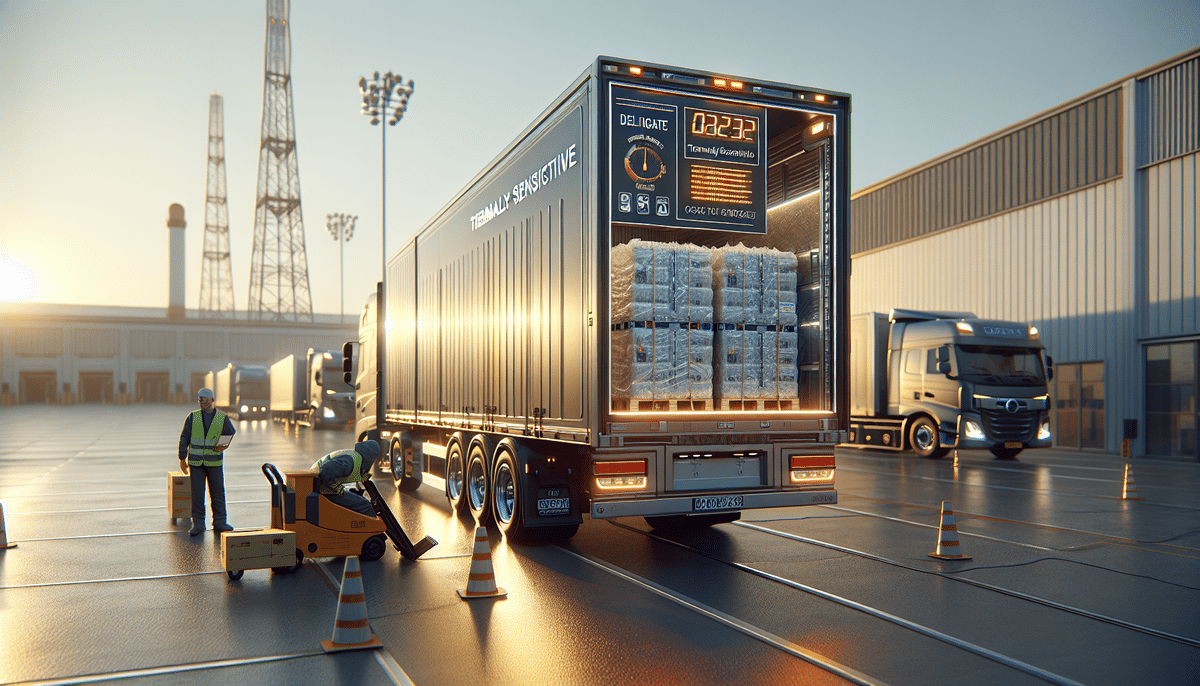

UPS Guidelines for Temperature-Controlled Shipping

UPS has established comprehensive guidelines to ensure the safe and efficient shipping of temperature-sensitive items. These guidelines involve the use of insulated containers, temperature-monitoring devices, and customized packaging solutions tailored to specific product requirements.

Insulated Packaging Solutions

UPS utilizes insulated packaging materials designed to maintain the desired temperature range throughout the shipping process. These materials include advanced insulation and reflective barriers to minimize temperature fluctuations.

Temperature Monitoring Technologies

Innovative temperature-monitoring devices enable real-time tracking of shipment temperatures. These devices alert UPS personnel to any deviations, allowing for immediate corrective actions to safeguard product integrity.

Customized Shipping Options

UPS offers customized shipping options for various industries, including pharmaceuticals and food services, ensuring that each shipment meets the specific temperature control requirements.

Best Practices for Packaging and Labeling

Choosing the Right Packaging Materials

Selecting appropriate packaging materials is essential for maintaining temperature stability. UPS recommends using insulated containers combined with suitable cushioning materials to protect against physical damage and temperature variations.

Proper Labeling

Accurate labeling ensures that temperature-sensitive packages are handled correctly. Labels should clearly indicate the required temperature range, handling instructions, and any special considerations to alert carriers and handlers.

Utilizing Cooling Agents

Incorporating cooling agents such as gel packs or dry ice can help maintain the necessary temperature throughout the transit period. The choice of cooling agent should align with the product's specific temperature requirements and shipping duration.

Monitoring and Tracking During Transit

Real-Time Temperature Tracking

Implementing real-time temperature tracking allows for continuous monitoring of shipments. UPS's temperature-monitoring solutions provide ongoing data that can be accessed by both the sender and receiver to ensure compliance with temperature specifications.

Data Loggers

Data loggers record temperature readings at regular intervals, offering a detailed account of the temperature conditions during transit. This data is crucial for identifying any anomalies and taking corrective actions if necessary.

Staff Training

Proper training for staff involved in the handling and shipping of temperature-sensitive items is vital. Employees should understand the importance of temperature control and the protocols for responding to any temperature deviations.

Future Innovations in Temperature-Controlled Shipping

UPS is continually investing in new technologies to enhance temperature-controlled shipping solutions. Recent innovations include the development of packaging materials with phase change materials (PCMs) that automatically regulate temperature, reducing the reliance on external cooling agents and improving shipping efficiency.

Additionally, UPS is exploring the integration of Internet of Things (IoT) devices for more sophisticated monitoring and data analytics, enabling predictive maintenance and proactive management of temperature-sensitive shipments.

These advancements position UPS at the forefront of reliable and efficient temperature-controlled logistics, catering to the growing demand for safe transportation of sensitive products.

Preparing Your Shipment for Transport and Delivery

Effective preparation is critical for the successful shipping of temperature-sensitive items. Key steps include:

- Selecting Appropriate Shipping Methods: Choose shipping options that align with the product's temperature requirements and delivery timelines.

- Using Proper Packaging and Insulation: Ensure that packaging materials are suitable for maintaining the desired temperature range.

- Compliance with Regulations: Verify that all shipping practices comply with relevant regulations and guidelines to avoid legal issues.

- Accurate Labeling: Clearly label packages with necessary handling instructions and temperature requirements.

- Tracking Shipments: Utilize tracking tools to monitor the progress and condition of shipments in real-time.

By adhering to these preparation steps, businesses can minimize risks and ensure the safe delivery of temperature-sensitive items.

Conclusion

Maintaining proper temperature control during shipping is essential for preserving the quality and safety of sensitive items. UPS's comprehensive guidelines and innovative solutions provide robust support for businesses aiming to transport temperature-sensitive products efficiently and reliably. By implementing best practices in packaging, labeling, and temperature monitoring, companies can mitigate risks, comply with regulatory standards, and uphold their reputation for delivering high-quality products.

As technology continues to advance, UPS remains committed to enhancing its temperature-controlled shipping capabilities, ensuring that the evolving needs of various industries are met with precision and care.