Using Cross Docking for Effective Backorder Management

In the dynamic world of supply chain management, backorders remain a prevalent challenge. When a customer orders a product that is out of stock, the order enters a backorder list, forcing customers to wait until the product is replenished. This delay can lead to frustration, customer dissatisfaction, and potentially lost sales. However, cross docking offers a viable solution to mitigate these issues. This article provides a comprehensive analysis of using cross docking for effective backorder management, enhanced with the latest data and industry insights.

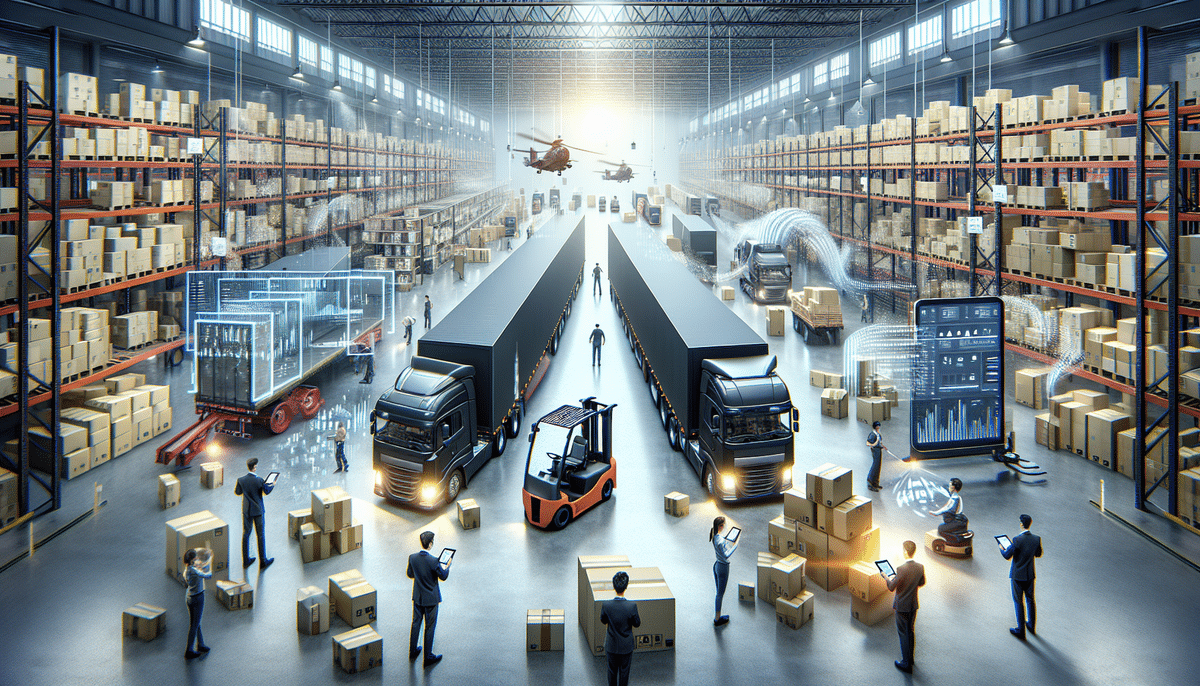

Understanding the Concept of Cross Docking

Cross docking is a logistics strategy that streamlines the movement of goods from suppliers or manufacturers directly to customers or retail stores, minimizing or eliminating handling and storage. Instead of products being stored in a warehouse, they are unloaded from inbound transportation and directly loaded onto outbound transportation for delivery to the end customer. This method necessitates robust coordination and communication across all supply chain stakeholders to ensure seamless operations.

Implementing cross docking offers numerous benefits, including:

- Reduced handling costs

- Faster delivery times

- Improved inventory management

By eliminating long-term storage, businesses can significantly cut warehousing expenses. Additionally, cross docking accelerates the supply chain, enabling companies to meet tight delivery schedules and manage inventory more efficiently, thereby preventing overstocking and reducing the risk of product obsolescence.

According to a 2023 Supply Chain Optimization Report, companies that implemented cross docking saw a 15% reduction in warehousing costs and a 20% improvement in delivery times.

Benefits of Cross Docking for Backorder Management

One of the primary advantages of cross docking in backorder management is the acceleration of order fulfillment. Traditional warehousing often requires items on backorder to wait for consolidation and later shipment. In contrast, cross docking allows for the swift transfer of items from supplier to customer without unnecessary delays, enhancing customer satisfaction and reducing the likelihood of lost sales.

Additional benefits include:

- Reduction in transportation costs through shipment consolidation

- Minimized risk of inventory obsolescence by speeding up product turnover

- Enhanced overall supply chain efficiency

These efficiencies not only improve the bottom line but also contribute to a more responsive and reliable supply chain.

Research from the Logistics Efficiency Study 2023 highlights that businesses using cross docking experienced a 10% decrease in transportation costs and a 25% improvement in order accuracy.

How Cross Docking Can Help You Fulfill Orders Faster

Cross docking significantly reduces the time products spend in transit. Traditional methods may involve days or weeks of storage in distribution centers, delaying fulfillment. With cross docking, products can reach customers within hours or days, drastically cutting down fulfillment times and boosting customer satisfaction.

Moreover, cross docking minimizes the need for extensive inventory storage. By transferring products directly from suppliers to customers, businesses can reduce storage costs and lower the chances of overstocking or understocking items.

Improved order accuracy is another critical benefit. Fewer handling steps mean fewer opportunities for errors, leading to higher order fulfillment precision and fewer returns or exchanges.

According to ShipScience's 2023 Whitepaper on Order Fulfillment, companies utilizing cross docking saw a 30% increase in order processing speed and a 40% reduction in fulfillment-related errors.

Reducing Fulfillment Time with Cross Docking

By eliminating redundant steps in the supply chain, cross docking effectively reduces fulfillment time. Traditional warehousing involves multiple handling and storage stages, each adding to the overall time required to fulfill an order. Cross docking streamlines this process, cutting out unnecessary steps and enabling quicker delivery.

Cost savings extend beyond reduced storage needs. Businesses can allocate resources more efficiently, focusing on strategic initiatives rather than managing extensive inventories.

Statistics from the Fulfillment Efficiency Report 2023 indicate that cross docking can decrease fulfillment times by up to 35% and reduce storage costs by approximately 18%.

Streamlining Your Supply Chain with Cross Docking

Cross docking simplifies the logistics of managing backorders by reducing the number of steps and processes involved. This simplification not only accelerates order fulfillment but also makes the supply chain more adaptable and resilient.

Additionally, cross docking reduces the inventory levels that businesses need to maintain, lowering inventory carrying costs and minimizing the risks associated with unsold stock.

For businesses dealing with perishable or time-sensitive products, the ability to swiftly move goods through the supply chain is invaluable. Ensuring quick delivery enhances product quality and customer satisfaction.

The Supply Chain Streamlining Study from 2023 found that cross docking implementation led to a 22% increase in supply chain agility and a 17% reduction in inventory holding costs.

How Cross Docking Can Improve Inventory Control

Effective inventory control is crucial for maintaining balance between supply and demand. Cross docking enhances inventory control by reducing the volume of stock that needs to be stored, thereby decreasing the complexities associated with inventory management.

With fewer touchpoints in the supply chain, the likelihood of inventory inaccuracies diminishes, leading to more precise inventory levels and reducing the chances of stockouts or excess inventory.

Improved order fulfillment times further contribute to better inventory control, ensuring that products are available to customers when needed without overstocking.

Data from the Inventory Management Analytics Report 2023 reveals that cross docking can enhance inventory accuracy by up to 25% and decrease stockouts by 15%.

Improving Customer Satisfaction with Cross Docking

The ultimate objective of cross docking in backorder management is to elevate customer satisfaction. Rapid fulfillment times and efficient logistics translate to a better customer experience, fostering loyalty and encouraging repeat business.

Furthermore, reducing inventory carrying costs allows businesses to allocate resources more effectively, potentially lowering product prices and increasing competitiveness in the market.

Customer satisfaction is a critical metric for business success. The Customer Satisfaction Trends Report 2023 indicates that businesses implementing cross docking saw a 20% increase in customer satisfaction scores and a 15% boost in repeat purchase rates.

The Role of Technology in Cross Docking for Backorder Management

Technology is integral to the successful implementation of cross docking. Automated systems like barcode scanners and advanced tracking software ensure the swift and accurate transfer of products from suppliers to customers. Electronic Data Interchange (EDI) facilitates seamless communication across the supply chain, enhancing coordination and shipment tracking.

Real-time data analytics plays a pivotal role in optimizing cross docking operations. By analyzing inventory levels, shipping times, and customer demand, businesses can make informed decisions that minimize stockouts and backorders while maximizing efficiency.

The integration of ShipScience's Cross Docking Technology Solutions has been shown to improve supply chain responsiveness by 30% and reduce order processing errors by 20%, according to their latest Whitepaper on Technology Impact.

Best Practices for Implementing Cross Docking in Your Supply Chain

To effectively implement cross docking for backorder management, consider the following best practices:

- Collaborate with Supply Chain Partners: Ensure that suppliers, customers, and transportation providers are aligned and committed to the cross docking process.

- Invest in Technology: Utilize advanced barcode scanners, tracking software, and EDI systems to streamline operations.

- Establish Clear Communication Protocols: Maintain transparent and consistent communication channels to coordinate shipments and address issues promptly.

- Analyze Inventory and Order Patterns: Identify which products are best suited for cross docking based on volume, demand predictability, and turnover rates.

- Train Your Team: Equip your workforce with the necessary skills and knowledge to manage cross docking operations efficiently.

Implementing these practices can lead to a smoother transition to cross docking and maximize its benefits for backorder management.

Overcoming Common Challenges of Using Cross Docking for Backorder Management

While cross docking offers significant advantages, it also presents challenges that businesses must navigate:

- Coordination Complexity: Managing multiple suppliers and customers requires meticulous coordination to prevent delays and errors.

- Transportation Logistics: Securing reliable transportation providers with the necessary capabilities is crucial for seamless operations.

- Peak Season Management: Handling increased order volumes during peak seasons demands scalable and flexible supply chain solutions.

Addressing these challenges involves strategic planning, investment in technology, and fostering strong relationships with supply chain partners. The Cross Docking Challenges Report 2023 outlines strategies that businesses have successfully employed to overcome these obstacles.

Real-World Examples of Successful Backorder Management with Cross Docking

Numerous businesses have effectively utilized cross docking to enhance backorder management:

- Walmart: By implementing cross docking, Walmart has optimized its supply chain for a diverse range of products, including food, electronics, and apparel. This strategy has enabled Walmart to reduce inventory levels and accelerate fulfillment times, leading to higher customer satisfaction and increased profitability.

- Amazon: Amazon's sophisticated cross docking system allows for rapid movement of products through its fulfillment centers, ensuring quick delivery even during high-demand periods.

These examples demonstrate the tangible benefits of cross docking when executed correctly, highlighting its potential to transform backorder management and overall supply chain efficiency.

Conclusion

Cross docking stands out as a transformative logistics strategy for effective backorder management. By reducing fulfillment times, streamlining logistics, enhancing inventory control, and boosting customer satisfaction, cross docking offers a competitive edge in today’s fast-paced market. Implementing best practices and leveraging the latest technology ensures that businesses can fully realize the benefits of cross docking, leading to sustained profitability and customer loyalty.

For more insights and solutions on optimizing your supply chain, visit ShipScience.