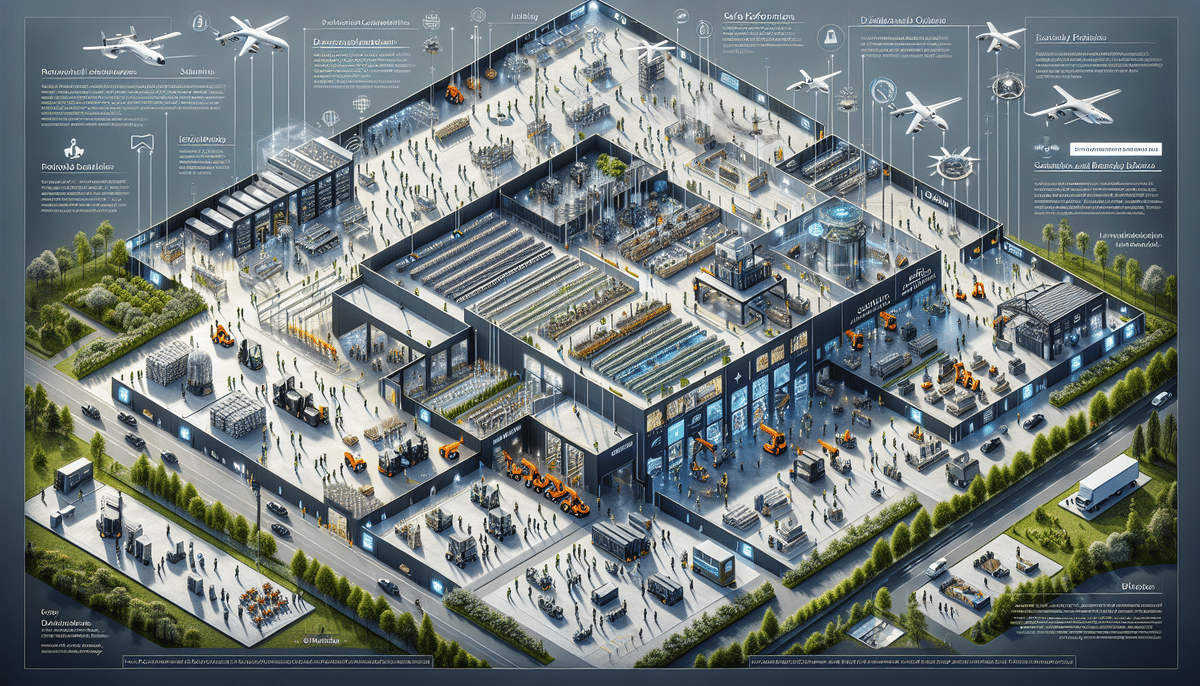

Effective Warehouse Management Processes: Tips for Success

Effective warehouse management is essential for any organization that deals with inventory and products. From tracking incoming shipments to managing outgoing orders, warehouse management processes play a critical role in ensuring optimal efficiency, productivity, and, ultimately, business success. In this article, we will explore the key elements of effective warehouse management, the processes that ensure optimal efficiency, and tips for developing a comprehensive warehouse management plan.

Understanding the Importance of Efficient Warehouse Management

The success of any business directly depends on the efficiency of its warehouse management. This includes everything from receiving, storing, picking, packing, and shipping products to handling returns and inventory management. Inefficient warehouse management processes can lead to ineffective inventory management, lost or damaged products, low productivity, and increased overhead costs. Conversely, well-managed warehouses can significantly improve efficiency, boost productivity, and increase customer satisfaction.

One of the key benefits of efficient warehouse management is the ability to quickly respond to customer demands. With a well-organized warehouse, businesses can easily track inventory levels and ensure that products are always in stock. According to a Logistics Management report, companies with optimized warehouse management systems experience a 20% increase in order fulfillment speed, leading to higher customer satisfaction and loyalty.

In addition, efficient warehouse management can help businesses reduce their environmental impact. By optimizing inventory levels and reducing waste, companies can minimize their carbon footprint and contribute to a more sustainable future. This not only benefits the environment but can also improve a company's reputation and attract environmentally conscious customers.

Key Elements of Effective Warehouse Management

The key elements of effective warehouse management include:

- Optimizing Warehouse Layout: Maximizing space utilization and ensuring efficient product flow by strategically arranging items to reduce travel time for pickers and ensure easy accessibility for stock management.

- Efficient Inventory Management Practices: Keeping track of inventory levels, orders, returns, and stock replenishment to maintain optimal stock levels.

- Robust Order Fulfillment System: Ensuring that orders are picked correctly, packed and shipped on time, and delivered to customers as expected.

In addition to these key elements, effective warehouse management involves implementing safety measures to ensure the well-being of employees and the protection of inventory. This includes providing proper training for employees on handling equipment and materials, as well as maintaining a clean and organized work environment to prevent accidents and product damage.

Another important aspect is utilizing technology to streamline processes and improve efficiency. Implementing a warehouse management system (WMS) can automate inventory tracking and order fulfillment. Additionally, using barcode scanners and other tools helps reduce errors and increase accuracy.

Warehouse Management Processes That Ensure Optimal Efficiency

Advanced Warehouse Management Systems (WMS) and Inventory Management Systems (IMS)

Warehouse Management Systems (WMS) or Inventory Management Systems (IMS) can automate order fulfillment, reduce manual labor, and streamline warehouse processes. These systems track inventory levels, generate reports, and streamline workflows, providing real-time updates to warehouse staff and managers. According to a study by Logistics Management, businesses using advanced WMS technologies have seen a 25% reduction in operational costs.

Barcode and RFID Technology

Incorporating barcode and RFID technology enhances accuracy, reduces errors, and improves efficiency. For example, RFID can increase inventory accuracy from 60% to over 95%, as reported by RFID Journal.

Efficient Shipment Management

Managing the flow of incoming and outgoing shipments is crucial for optimal efficiency. Implementing a first-in, first-out (FIFO) inventory system, cross-docking, and other methods that prioritize speed and efficiency can significantly enhance warehouse operations.

Training and Communication

Proper training and communication among warehouse staff are essential for maintaining optimal efficiency. Training on the use of WMS or IMS systems, safety protocols, and best practices for handling and storing products can improve productivity and reduce errors. Establishing clear communication channels between warehouse staff and management ensures that issues or concerns are addressed promptly.

Developing a Comprehensive Warehouse Management Plan

Developing a comprehensive warehouse management plan involves considering factors such as staff training, safety, security, automation, and sustainability. Key tips include:

- Staff Training and Development: Equip staff with the knowledge, skills, and tools to handle inventory accurately and efficiently.

- Safety and Security: Follow safety guidelines, install security cameras, use RFID tracking, and implement other technologies to monitor warehouse traffic and prevent theft or damage.

- Automation: Incorporate automated storage and retrieval systems, conveyor belts, and robotics to streamline processes, reduce errors, and increase efficiency.

- Sustainability Practices: Use energy-efficient lighting and equipment, reduce waste, and recycle materials to minimize the environmental footprint.

By developing a comprehensive warehouse management plan that addresses these factors, organizations can improve efficiency, productivity, and customer satisfaction while reducing costs, enhancing safety and security, and promoting sustainability.

The Role of Technology in Modern Warehouse Management

Technology plays a vital role in modern warehouse management, especially with the adoption of automation, robotics, and other advanced technologies. Key technologies include:

- Warehouse Management Systems (WMS): Enhance efficiency and streamline processes by providing real-time updates and analytics.

- Enterprise Resource Planning (ERP) Software: Integrates various business processes, including inventory and order management.

- Transportation Management Systems (TMS): Optimize shipping and logistics operations.

Many organizations are exploring the use of drones and autonomous vehicles for order fulfillment processes, which can reduce shipping times and improve accuracy. Additionally, the integration of artificial intelligence (AI) and machine learning tools into warehouse management systems can enhance forecasting, demand planning, and inventory optimization, leading to greater efficiency and productivity.

Virtual and augmented reality technologies are also transforming warehouse management by providing immersive training experiences for staff. These technologies allow employees to gain hands-on experience in a safe and controlled environment, reducing the risk of accidents and errors while improving overall efficiency.

Furthermore, technology enhances supply chain visibility and transparency. With the use of sensors and other tracking technologies, warehouse managers can gain real-time insights into inventory levels, shipping times, and other critical data points. This facilitates the identification of potential bottlenecks and inefficiencies, enabling data-driven decisions that improve overall warehouse performance.

Overcoming Common Challenges in Warehouse Management

Despite the importance of efficient warehouse management, organizations may encounter several common challenges, including poor inventory management, low productivity, improper storage, and staffing issues. To overcome these challenges:

- Conduct Regular Inventory Audits: Reduce the chance of stock discrepancies and minimize the risk of stockouts by regularly auditing inventory.

- Implement Robust Training Programs: Enhance staff productivity and minimize errors by providing comprehensive training and development programs.

- Enhance Communication: Use a centralized system for communication and collaboration between departments to prevent delays and inaccuracies.

- Optimize Storage Solutions: Implement efficient storage methods to maximize space utilization and ensure easy access to products.

Addressing these challenges through a thorough warehouse management plan and best practices can help organizations maintain efficient operations and improve overall performance.

Measuring Success: Key Performance Indicators (KPIs) in Warehouse Operations

To ensure that warehouse management processes are as efficient as possible, it is essential to monitor key performance indicators (KPIs). Important KPIs include:

- Inventory Turnover: Measures how often inventory is sold and replaced over a specific period.

- Order Cycle Time: The average time taken from receiving an order to its delivery.

- Picking Accuracy: The rate at which orders are picked correctly without errors.

- Overall Productivity: Assesses the efficiency of warehouse operations and staff performance.

By tracking these metrics, organizations can identify areas for improvement and make data-driven decisions to optimize their warehouses for maximum efficiency and productivity. Implementing a WMS can facilitate accurate KPI tracking and provide actionable insights.

Creating a Safe and Secure Work Environment

Creating a safe and secure work environment is essential for any warehouse operation. Key strategies include:

- Implementing Safety Measures: Use proper signage, adequate lighting, and safety equipment to reduce the risk of accidents and injuries.

- Installing Security Systems: Utilize security cameras, RFID tracking, and other technologies to prevent theft and protect products.

- Training Staff: Educate employees on safety procedures and best practices to promote a culture of safety and minimize risks.

According to the Occupational Safety and Health Administration (OSHA), implementing comprehensive safety programs can reduce workplace injuries by up to 50%.

Integrating Sustainability into Warehouse Management

Warehouses can have a significant environmental impact through energy use, waste production, and carbon emissions. To reduce their environmental footprint, organizations can integrate sustainable practices into their warehouse management strategy, such as:

- Energy-Efficient Lighting and Equipment: Install LED lighting and energy-efficient machinery to reduce energy consumption.

- Reducing Packaging Size: Optimize packaging to minimize material usage and waste.

- Recycling Materials: Implement recycling programs for materials like cardboard, plastics, and metals.

- Optimizing Inventory Levels: Reduce excess inventory to minimize storage space and associated energy usage.

Adopting these sustainability practices not only benefits the environment but can also lead to cost savings and enhance the company's reputation among environmentally conscious consumers.

Training and Development for Warehouse Success

Training and development are critical components of successful warehouse management. Effective strategies include:

- Comprehensive Training Programs: Provide initial and ongoing training to ensure staff members are proficient in their roles and knowledgeable about best practices.

- Continuous Improvement Culture: Encourage a culture of continuous improvement where employees are motivated to enhance their skills and contribute to process improvements.

- Use of Technology Training: Train staff on the latest technologies and systems used in the warehouse to maximize their effectiveness and efficiency.

Organizations that invest in employee training and development report higher productivity rates and lower turnover, according to a SHRM survey.

Best Tools and Resources for Managing a Successful Warehouse

Several tools and resources can assist organizations in managing successful warehouse operations, including:

- Inventory Management Software: Solutions like WMS provide real-time updates and analytics to streamline operations.

- RFID and Barcode Technology: Enhance accuracy and efficiency in product tracking and inventory management.

- Drones and Autonomous Vehicles: Reduce shipping times and improve order accuracy through automated processes.

- Artificial Intelligence (AI) and Machine Learning: Improve inventory forecasting and optimize warehouse processes through predictive analytics.

Utilizing these tools can lead to significant improvements in warehouse efficiency, accuracy, and overall performance.

This article has explored the importance of efficient warehouse management, the key elements of effective warehouse management, and the processes that ensure optimal efficiency. By developing a comprehensive warehouse management plan, integrating technology, and prioritizing safety, security, and sustainability, organizations can improve efficiency, reduce costs, and increase customer satisfaction. With the constant advancement of technology and a growing focus on sustainability, the future of warehouse management is promising. Organizations that prioritize best practices and innovation will remain competitive and continue to thrive.