Understanding CBM: A Comprehensive Overview

CBM, or Cubic Meter, is a fundamental unit of measurement crucial in industries such as logistics, supply chain management, manufacturing, and construction. This guide delves into the origins and history of CBM, explores its various definitions, highlights its significance across different sectors, provides a step-by-step calculation method, discusses its advantages and limitations, examines its applications in logistics and supply chains, assesses how technology enhances CBM accuracy, clarifies common misconceptions, presents a case study on predictive maintenance using CBM, outlines future trends, and offers best practices for implementing CBM strategies.

The Origins and Evolution of CBM

The concept of CBM dates back to early human civilizations where measuring the volume of objects was essential for trade, construction, and resource management. The development of standardized units like the meter and liter paved the way for the adoption of the cubic meter as a universal volume measurement. With the rise of global trade, a standardized unit such as CBM became indispensable for facilitating international commerce and ensuring consistency across different regions.

Today, CBM is integral to industries worldwide, enabling precise volume calculations for cargo shipping, material estimation in construction, and resource management in various sectors.

Defining CBM Across Different Contexts

CBM in Volume Measurement

Generally, CBM refers to the volume of space an object occupies in a three-dimensional space, calculated by multiplying its length, width, and height in meters. For instance, a rectangular box measuring 2m x 3m x 4m has a CBM of 24 cubic meters.

CBM in the Oil and Gas Industry

In this sector, CBM stands for Coalbed Methane, a form of natural gas extracted from coal seams. Coalbed methane plays a significant role in energy production, providing a cleaner alternative to other fossil fuels.

CBM in Education

Here, CBM stands for Curriculum-Based Measurement, an assessment tool used to monitor student progress in academics such as reading, writing, and mathematics. It involves regular, brief evaluations aligned with the curriculum to guide instructional decisions.

The Importance of CBM in Various Industries

CBM is a critical metric in several industries, enhancing efficiency and reducing costs:

- Logistics and Supply Chain: Optimizes cargo space, reduces transportation costs, and ensures compliance with volume regulations.

- Manufacturing: Assists in product design, raw material estimation, and production planning.

- Construction: Facilitates accurate volume calculations for materials like concrete and soil, ensuring project accuracy and compliance.

- Pharmaceuticals: Ensures precise measurement of liquid medications and raw materials, vital for dosage accuracy and production efficiency.

- Furniture Industry: Aids in space planning for storage and transportation, optimizing inventory management.

According to a Statista report, the global logistics market is projected to reach $12.68 trillion by 2027, underscoring the growing importance of metrics like CBM in optimizing operations.

Calculating CBM: A Step-by-Step Guide

Calculating CBM is straightforward, especially for regularly shaped objects:

- Measure Dimensions: Obtain the length, width, and height of the object in meters.

- Calculate Volume: Multiply these three dimensions to get the volume in cubic meters. Formula: Length × Width × Height = CBM

- Irregular Shapes: For objects with irregular shapes, use mathematical formulas or divide the object into smaller regular shapes and sum their volumes.

- Unit Conversion: Convert CBM to other units like liters or gallons if necessary. (1 CBM = 1,000 liters)

Accurate CBM calculations are essential for determining shipping costs and ensuring efficient use of transportation resources.

Advantages and Limitations of CBM

Advantages

- Standardization: Provides a universal volume measurement recognized globally.

- Efficiency: Facilitates optimal space utilization in storage and transportation.

- Cost Reduction: Helps in minimizing transportation and storage costs by maximizing space usage.

Limitations

- Excludes Weight and Density: CBM does not account for the weight or density of objects, which can influence shipping costs and handling requirements.

- Assumes Perfect Packing: Real-world packing inefficiencies can lead to discrepancies between calculated and actual volume usage.

- Challenges with Irregular Shapes: Accurately measuring CBM for irregularly shaped objects can be complex and time-consuming.

For a balanced approach, CBM should be used alongside other metrics like weight and density to provide a comprehensive understanding of shipping and storage requirements.

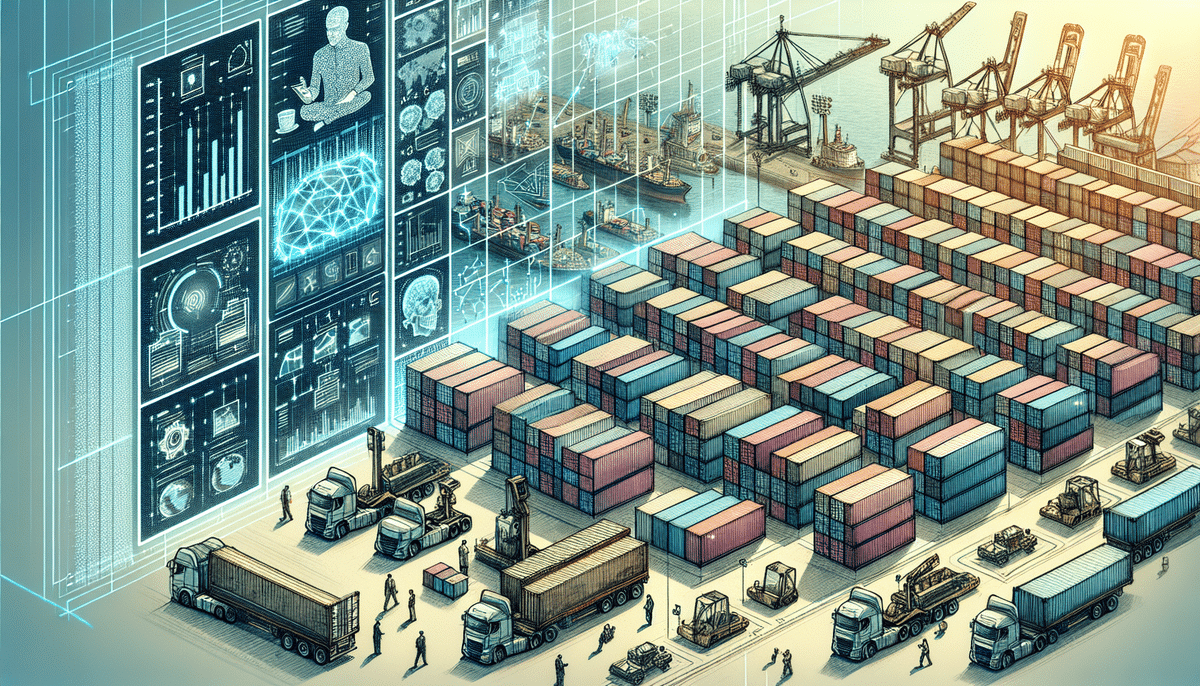

Applications of CBM in Logistics and Supply Chains

In logistics and supply chain management, CBM is indispensable for:

- Space Optimization: Ensures maximum utilization of cargo space in containers and trucks.

- Cost Estimation: Aids in accurately estimating shipping costs based on volume.

- Regulatory Compliance: Helps in adhering to international volume and weight regulations.

- Route Planning: Facilitates efficient route and load planning to minimize transportation time and costs.

Effective CBM management can lead to significant cost savings and enhanced operational efficiency. According to the McKinsey & Company, optimizing supply chain operations can reduce costs by up to 20%.

Enhancing CBM Accuracy Through Technology

Advancements in technology have significantly improved CBM accuracy and application:

- 3D Scanning and Imaging: Provides precise measurements of objects, reducing errors in CBM calculations.

- Software Solutions: Specialized logistics software automates CBM calculations, integrating them with inventory and shipping systems.

- IoT Integration: Sensors and IoT devices monitor real-time volume and environmental conditions, enhancing CBM data reliability.

These technologies not only streamline CBM processes but also integrate seamlessly with other operational systems, providing a holistic view of supply chain dynamics. For more on the impact of technology in logistics, refer to this Forbes article.

Common Misconceptions About CBM

Several misconceptions about CBM persist:

- CBM Only Applies to Solids: CBM is versatile and applicable to liquids and gases as well, provided their volume can be accurately measured.

- CBM Equals Weight: CBM measures volume, not weight. While related, they are distinct metrics used for different purposes.

- CBM is a Secondary Metric: In industries like logistics, CBM is a primary metric essential for cost estimation and space optimization.

Understanding the true nature of CBM ensures its effective application in various operational contexts.

Case Study: Predictive Maintenance Utilizing CBM

Predictive maintenance leverages CBM to foresee equipment failures before they occur. By monitoring CBM-related parameters such as volume changes, pressure variations, and temperature fluctuations, organizations can predict maintenance needs accurately.

Aviation Industry: Airlines use CBM to monitor engine performance, detecting anomalies that might indicate potential failures. This proactive approach enhances safety and reduces unexpected downtime.

Manufacturing Sector: Manufacturers implement CBM to oversee production line metrics, identifying deviations that signal equipment wear and the need for maintenance, thereby maintaining continuous production flow.

According to a study by IEA, predictive maintenance can reduce maintenance costs by 10-40% and decrease unplanned downtime by up to 50%.

Future Trends and Developments in CBM

The future of CBM is shaped by ongoing technological advancements and evolving industry needs:

- Artificial Intelligence and Machine Learning: These technologies enhance predictive maintenance and optimize logistics by analyzing complex CBM data patterns.

- Blockchain Integration: Ensures transparency and traceability in CBM data, improving accountability in supply chains.

- Sustainability Initiatives: CBM contributes to circular economy practices by optimizing resource usage and reducing waste.

- Advanced Measurement Standards: The development of new standards ensures more accurate and consistent CBM measurements across industries.

Embracing these trends will enable industries to harness the full potential of CBM, driving efficiency and sustainability. For insights on future logistics trends, refer to the Gartner report.

Best Practices for Implementing CBM Strategies

To effectively implement CBM strategies, organizations should consider the following best practices:

- Define Clear Objectives: Establish what you aim to achieve with CBM, such as cost reduction, space optimization, or enhanced accuracy.

- Integrate with Business Metrics: Align CBM with other key performance indicators to ensure cohesive operational strategies.

- Invest in Technology: Utilize advanced tools and software to automate and enhance CBM calculations and data management.

- Employee Training: Educate staff on the importance of CBM and how to apply it effectively in their roles.

- Collaborate with Stakeholders: Engage partners and suppliers in CBM processes to ensure consistency and accuracy across the supply chain.

- Continuous Monitoring and Evaluation: Regularly assess the effectiveness of CBM strategies and make necessary adjustments based on performance data.

Adopting these best practices ensures that organizations fully leverage CBM, resulting in improved efficiency, cost savings, and a competitive edge in their respective industries.

Conclusion

CBM is an indispensable metric that underpins efficiency and effectiveness across a multitude of industries. From optimizing space in logistics to enhancing predictive maintenance in manufacturing, understanding and utilizing CBM can lead to significant operational improvements and cost savings. By leveraging advanced technologies and adhering to best practices, organizations can maximize the benefits of CBM, ensuring sustained growth and competitiveness in an increasingly data-driven world.