What Does Order Fulfillment Cost? A Comprehensive Guide

Order fulfillment cost is a critical aspect of any business's operations, encompassing all expenses incurred from the moment a product is sold to its final delivery to the customer. Understanding the intricacies and factors that influence order fulfillment costs is vital for optimizing a business's profitability. In this updated guide, we delve deep into everything you need to know about order fulfillment costs in 2023.

Understanding the Basics of Order Fulfillment Cost

Order fulfillment cost comprises several components, including:

- Cost of Goods Sold (COGS): This includes the cost of raw materials, manufacturing, and production.

- Warehousing and Storage Costs: Expenses related to storing inventory, including rent, utilities, and maintenance.

- Shipping and Handling Costs: Costs incurred in packaging and delivering products to customers.

- Labor Costs: Wages and benefits for employees involved in the fulfillment process.

- Packaging Costs: Expenses for materials used to package products safely.

- Overhead Costs: General business expenses such as administrative costs and utilities.

These costs can fluctuate based on factors like the nature of the product, business location, sales volume, and more. According to a Statista report, the average order fulfillment cost per order in the e-commerce industry is estimated to be around $5.00, though this can vary widely based on the aforementioned factors.

Optimizing each component is essential to maximize profits. For instance, keeping the cost of goods sold as low as possible without compromising quality is crucial. Effective inventory management and negotiating better rates with suppliers can significantly impact COGS.

Labor costs are another significant component. These include wages and benefits for warehouse workers, packers, and shippers. As per the Bureau of Labor Statistics, the median hourly wage for warehouse workers is approximately $16.00, but this can vary based on location and skill level. Efficient management of labor costs ensures they do not erode your profit margins.

Factors That Affect Order Fulfillment Cost

Several factors influence the total cost of order fulfillment:

- Shipping Destination and Method: International shipping generally incurs higher costs compared to domestic shipping.

- Product Weight and Dimensions: Heavier and bulkier items cost more to ship.

- Inventory Management Practices: Efficient inventory management can reduce storage costs and prevent stockouts or overstocking.

- Workforce Productivity: Higher productivity can reduce labor costs per order.

- Packaging Materials: The type and quality of packaging materials used can impact both costs and customer satisfaction.

- Level of Customization: Customized orders may require additional labor and materials, increasing fulfillment costs.

- Fulfillment Center Location: Locations with higher labor or real estate costs can increase overall fulfillment expenses.

Understanding these factors allows businesses to develop cost-effective fulfillment strategies. For example, utilizing regional fulfillment centers can reduce shipping times and costs, as highlighted in a report by Inbound Logistics.

Calculating Your Order Fulfillment Cost: A Step-by-Step Guide

- Determine the Total Cost of Goods Sold (COGS): Include raw materials, manufacturing, and production expenses.

- Calculate Warehousing and Storage Costs: Account for rent, utilities, and other storage-related expenses.

- Compute Shipping and Handling Costs: Include packaging materials, shipping fees, and carrier charges.

- Factor in Labor Costs: Incorporate wages, benefits, and any other employee-related expenses.

- Include Overhead Costs: General business expenses such as administrative costs.

- Calculate Total Cost Per Order: Sum all the above costs and divide by the number of orders to find the cost per order.

- Compare with Revenue: Subtract the total fulfillment cost per order from the revenue generated to determine profitability.

Regularly reviewing and updating your order fulfillment cost calculations is essential, as expenses and fees can fluctuate. Utilizing software solutions like shipping software can help automate and streamline this process, ensuring accurate and up-to-date calculations.

The Pros and Cons of In-House Order Fulfillment vs. Outsourcing to a Third-Party Provider

Deciding between in-house order fulfillment and outsourcing to a third-party provider significantly impacts fulfillment costs and performance:

In-House Order Fulfillment

Pros:

- Greater control over the fulfillment process and customization options.

- Better communication and collaboration between internal departments.

- Potential for establishing a quality brand image through personalized service.

Cons:

- High initial investment in infrastructure, equipment, and labor.

- Scalability can be challenging as the business grows.

- Responsibility for managing all aspects of fulfillment, including handling issues.

Outsourcing to a Third-Party Provider

Pros:

- Access to specialized expertise and advanced fulfillment technologies.

- Scalable resources that can grow with your business.

- Potential cost savings through economies of scale.

Cons:

- Less control over the fulfillment process and potential delays.

- Possible communication challenges and dependency on the provider.

- Costs can fluctuate based on usage and service levels.

Ultimately, the choice depends on the size, resources, and specific needs of your business. Smaller businesses may benefit more from outsourcing due to limited resources, while larger businesses might find in-house fulfillment more viable.

Common Mistakes That Can Increase Your Order Fulfillment Cost

Avoiding common pitfalls is crucial to keeping your fulfillment costs in check:

- Poor Inventory Management: Overstocks or stockouts can lead to increased storage costs and lost sales opportunities.

- Inefficient Shipping Methods: Using oversized packages or expensive courier services unnecessarily drives up costs.

- Incorrect Expense Calculations: Failing to account for all costs can result in mispricing and reduced profitability.

- Suboptimal Packaging: Using packaging materials that are too large or not durable enough can cause product damage and increase shipping costs.

- Lack of Process Optimization: Manual data entry errors and delays in processing orders can lead to inefficiencies and higher costs.

Implementing automation tools and regularly reviewing your fulfillment processes can help mitigate these issues and reduce costs. For example, using barcode scanners and automated inventory management systems can enhance accuracy and efficiency.

Tips for Reducing Your Order Fulfillment Cost Without Compromising Quality

Implementing strategic measures can help lower fulfillment costs while maintaining high-quality service:

- Optimize Inventory Management: Reduce lead times and adopt just-in-time inventory practices to minimize storage costs and reduce waste.

- Negotiate with Shipping Providers: Compare different shipping and handling providers to secure the most cost-effective rates.

- Invest in Automation: Utilize technologies like shipping software and barcode scanners to streamline workflows and lower labor costs.

- Improve Internal Processes: Regularly evaluate and enhance your fulfillment processes to eliminate inefficiencies and prevent costly errors.

- Build Strong Supplier Relationships: Negotiating better rates for raw materials through long-term partnerships can reduce overall production costs.

- Outsource Select Fulfillment Tasks: Consider outsourcing packaging and labeling to specialized providers who offer competitive rates.

- Implement Customer Self-Service Portals: Allow customers to track and manage their orders, reducing the workload on your customer service team and lowering associated costs.

By adopting these strategies, businesses can effectively reduce their order fulfillment costs while ensuring customer satisfaction and product quality.

How to Negotiate with Your Order Fulfillment Provider to Get the Best Price

Effective negotiation with your order fulfillment provider can lead to substantial cost savings:

- Analyze Current Fulfillment Costs: Prepare a detailed breakdown of your existing fulfillment expenses to understand where savings can be achieved.

- Research Alternative Providers: Explore other fulfillment providers to understand industry pricing standards and identify potential negotiation leverage.

- Propose Incentives: Offer incentives such as longer-term contracts or higher order volumes in exchange for better rates.

- Assess Provider Performance: Regularly evaluate your provider's performance and be prepared to renegotiate terms if necessary.

Approach negotiations with a collaborative mindset, aiming for mutually beneficial agreements. This fosters strong, long-term partnerships that can benefit both parties. Remember, while you seek better pricing, your provider also aims to maintain profitability, so finding a balance is key.

The Importance of Tracking Your Order Fulfillment Costs and Performance Metrics

Monitoring key metrics is essential for maintaining and improving fulfillment efficiency:

- Order Lead Times: The duration from order placement to delivery. Shorter lead times can enhance customer satisfaction and reduce inventory holding costs.

- Fulfillment Accuracy: The rate at which orders are correctly processed and shipped. High accuracy reduces returns and increases customer trust.

- Inventory Turnover Rates: How quickly inventory is sold and replaced. Higher turnover rates can indicate efficient inventory management.

- Shipping and Handling Costs: Tracking these costs helps identify areas where shipping expenses can be minimized.

- Customer Satisfaction: Gathering and analyzing customer feedback can highlight areas for improvement in the fulfillment process.

Regularly tracking these metrics enables businesses to identify inefficiencies, make informed decisions, and optimize their order fulfillment processes. Tools like order tracking software can facilitate this monitoring.

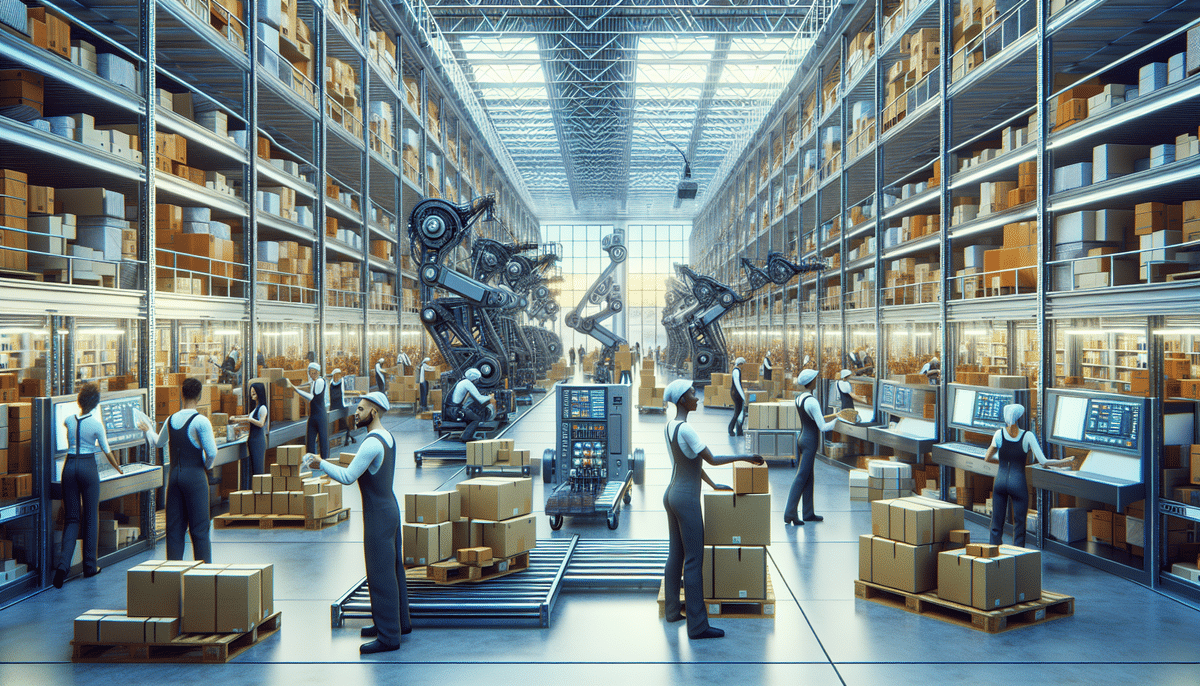

Trends in the Industry That Could Impact Your Order Fulfillment Costs in the Future

The order fulfillment landscape is continuously evolving, influenced by technological advancements and changing consumer expectations:

- Growth of E-Commerce: The increasing demand for online shopping drives the need for faster and more efficient fulfillment solutions.

- Automation and Robotics: The adoption of robotics in warehouses enhances efficiency and reduces labor costs, as seen in Amazon's fulfillment centers.

- Predictive Analytics: Utilizing data analytics to forecast demand and optimize inventory levels can lead to cost savings and improved service levels.

- Sustainable Packaging: The shift towards eco-friendly packaging materials meets consumer demand for sustainability, potentially reducing waste management costs over time.

- Omnichannel Fulfillment: Integrating multiple sales channels requires streamlined fulfillment processes to ensure consistency and efficiency.

- Same-Day Delivery: Increasing consumer expectations for same-day or next-day delivery may require investments in localized fulfillment centers.

Staying abreast of these trends allows businesses to adapt and innovate, maintaining cost-effectiveness and competitiveness in the market.

Real-Life Examples of Companies Successfully Managing Their Order Fulfillment Costs

Several companies have effectively managed their order fulfillment costs through innovative strategies:

- Amazon: Pioneered the use of robotics and automation in their fulfillment centers, significantly increasing processing speed and reducing labor costs.

- Walmart: Partnered with FedEx to offer same-day delivery services, leveraging FedEx's existing infrastructure to minimize additional investment costs.

- Zappos: Utilizes a centralized warehouse to streamline shipping processes, reducing handling costs while maintaining high customer service standards.

These examples demonstrate how strategic investments in technology and partnerships can lead to substantial cost savings and improved fulfillment efficiency.

Conclusion

Order fulfillment cost is a pivotal factor in a business's overall profitability. By comprehensively understanding the components of fulfillment costs, analyzing influencing factors, implementing cost-saving strategies, and diligently tracking performance metrics, businesses can optimize their fulfillment processes. Staying informed about industry trends and learning from successful companies can further enhance cost-effectiveness and maintain a competitive edge in the marketplace.