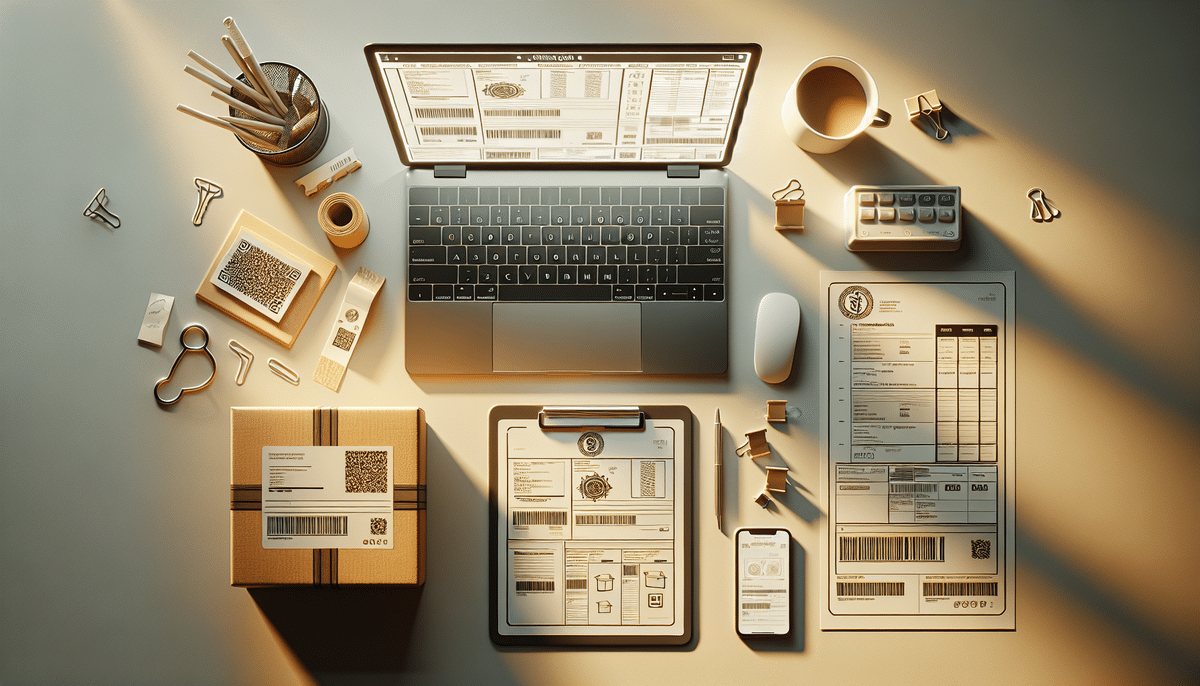

Understanding Packing Slips in Shipping and Logistics

Packing slips are vital documents in the shipping and logistics industry. They accompany shipments and provide detailed information about the contents of each package. By offering critical data, packing slips aid in identifying packages and managing inventory effectively. This article explores the definition of packing slips, their purpose, creation methods, essential information, common errors to avoid, and the comparison between electronic and printed packing slips. Additionally, it emphasizes the importance of accuracy and how technology can streamline packing slip usage.

The Purpose of Packing Slips in Shipping and Logistics

The primary function of a packing slip is to provide a comprehensive inventory of the items within a package. This detailed listing is essential for identifying packages and maintaining accurate inventory levels. Recipients can cross-reference items against the packing slip, ensuring shipments are complete and accurate. In cases of discrepancies, the packing slip helps identify missing or damaged items. Moreover, packing slips include crucial information such as the shipping address, sender's details, and billing information, facilitating efficient processing and billing.

Packing slips also serve as valuable references for future orders. By maintaining records of items included in each shipment, businesses can monitor inventory levels and reorder products as necessary, ensuring stock availability and timely fulfillment of customer orders. Additionally, packing slips help identify customer order trends, allowing businesses to adjust inventory and product offerings accordingly.

Creating Effective Packing Slips for Your Business

Steps to Create a Packing Slip

Creating a packing slip is a straightforward process that can be managed internally or outsourced to a third-party service. Most businesses utilize template software programs to design customized packing slips tailored to their specific needs. The creation process involves:

- Determining necessary details such as package contents, shipping address, and recipient's contact information.

- Including additional requirements to facilitate the shipment, such as barcodes or tracking numbers.

- Designing the layout to ensure all information is clear and accessible.

Once compiled, the packing slip can be printed and included with the shipment or sent electronically.

Ensuring Accuracy and Completeness

Accuracy and completeness of the packing slip are crucial to avoid shipment delays or issues. Incorporating barcodes or tracking numbers enhances package tracking during transit. Some companies also include promotional materials or thank-you notes alongside the packing slip to improve customer experience. A well-designed and informative packing slip can enhance the shipping process and leave a positive impression on customers.

Essential Information Included on a Packing Slip

The specific information on a packing slip can vary based on a company's requirements and the type of shipment. However, essential details typically include:

- Order number

- Invoice number

- Shipment date

- Recipient's name and address

- Packing list

- Tracking number

- Any additional information mandated by the recipient

Additionally, a detailed description of the shipped items, including quantities and any special handling or storage instructions, should be provided. This information assists recipients in identifying and appropriately managing the shipment contents.

The Benefits of Using Packing Slips in Business Operations

Utilizing packing slips offers numerous advantages for businesses:

- Inventory Tracking: Monitors inventory levels and ensures accurate shipping and delivery of items.

- Efficiency: Speeds up the delivery process and reduces the risk of lost or damaged items.

- Record-Keeping: Provides a documented record of shipped items, aiding in customer follow-ups and dispute resolution.

- Financial Management: Tracking item costs assists in monitoring expenses and profits, informing pricing and inventory decisions.

- Customer Satisfaction: Detailed packing slips reassure customers about their order accuracy and care in handling, fostering positive reviews and loyalty.

According to a study by Inbound Logistics, businesses that implement accurate packing slips experience a significant reduction in order errors and returns, enhancing overall operational efficiency.

Improving Inventory Management with Packing Slips

Packing slips play a crucial role in managing inventory by tracking items shipped and enabling recipients to verify shipments against the slip. This verification process ensures timely inventory replenishment and prevents stock discrepancies.

Additionally, packing slips help identify frequently returned items or those in high demand, enabling businesses to adjust their inventory accordingly. They also assist in detecting inventory discrepancies, indicating potential errors in the picking or packing process. Addressing these discrepancies helps businesses refine their processes, reducing errors and enhancing efficiency.

Furthermore, packing slips facilitate supplier performance tracking. By comparing packing slips with purchase orders, businesses can confirm receipt of accurate items from suppliers. Addressing any discrepancies with suppliers ensures the receipt of correct items in future orders, fostering strong supplier relationships and ensuring high-quality products.

Common Mistakes to Avoid When Creating Packing Slips

Accuracy is paramount when creating packing slips. Common mistakes include:

- Incorrect Shipping Addresses: Misaddressed packages can lead to delivery delays or returns.

- Wrong Billing Information: Inaccurate billing details can complicate financial transactions and record-keeping.

- Missing Items on the Packing List: Omissions can result in incomplete shipments and customer dissatisfaction.

To avoid these errors, businesses should double-check all information before preparing shipments and ensure that the packing slip precisely matches the order. Utilizing template software or outsourcing to professional printing services can further minimize mistakes.

Customizing Packing Slips to Meet Business Needs

Customizing packing slips to align with your business needs enhances the efficiency of your shipping and logistics processes. Customization involves tailoring the packing slip to include or exclude specific information relevant to your operations. Businesses can use software programs to design customizable templates or work with third-party printing companies to develop unique packing slip designs.

Custom packing slips ensure that all necessary information is included, reflecting your business's unique requirements and streamlining the shipping process. For example, including promotional messages or specific handling instructions can enhance customer experience and operational efficiency.

Electronic vs. Printed Packing Slips: A Comparative Analysis

Advantages of Electronic Packing Slips

- Cost-Effective: Eliminates the need for paper and printing resources.

- Environmentally Friendly: Reduces paper waste, supporting sustainable practices.

- Secure: Minimizes the risk of loss or unauthorized access.

- Customizable: Easily tailored to specific business needs and updated as necessary.

- Accessible: Can be accessed from multiple devices and locations, enhancing flexibility.

Drawbacks of Printed Packing Slips

Printed packing slips require physical handling and are more susceptible to human errors. They also necessitate storage space and can contribute to increased operational costs. While some businesses may still prefer printed slips for specific reasons, the trend is shifting towards electronic solutions for their efficiency and sustainability.

The Critical Role of Accuracy in Packing Slips

Accuracy in packing slips is critical to ensuring efficient shipment processes. Inaccurate information can lead to lost or damaged items, increased costs, and delayed deliveries. Businesses must ensure that all information on the packing slip is correct and aligns with the order details. Utilizing template software or outsourcing to professional services can help minimize errors and maintain consistency.

According to industry studies, accurate packing slips contribute to lower return rates and higher customer satisfaction. Implementing rigorous verification processes enhances overall operational reliability.

Leveraging Technology to Streamline Packing Slip Usage

Advancements in technology have significantly streamlined the creation and management of packing slips. Businesses can now use specialized software to generate and customize packing slips efficiently. Electronic packing slips offer several advantages over traditional printed versions, including ease of distribution, reduced environmental impact, and enhanced security.

By adopting electronic packing slips, businesses can save time and resources, minimize errors, and provide real-time access to shipment information. Integration with inventory management systems further enhances the accuracy and efficiency of packing slip usage.

Handling Issues with Missing or Incorrect Packing Slips

Addressing missing or incorrect packing slips promptly is crucial to maintaining smooth operations. Steps to handle such issues include:

- Locate the Packing Slip: Determine if the slip is misplaced or incorrectly attached to the shipment.

- Notify the Recipient: Inform the recipient of the issue, providing necessary details to rectify it.

- Resend the Correct Packing Slip: If the shipment is still in transit, send a revised packing slip.

- Provide a Refund or Replacement: If the shipment is complete, consider providing a refund or replacement for any missing or incorrect items.

Implementing a quality control process to verify packing slips before shipment can prevent such issues from arising.

Conclusion

Packing slips are indispensable in the shipping and logistics sector, providing detailed inventories of package contents, aiding in inventory management, and expediting the delivery process. The advantages of using packing slips include enhanced accuracy, streamlined shipping operations, and improved inventory control. By implementing the strategies discussed in this article, businesses can design customized packing slips that meet their unique needs, reduce errors, and elevate customer service quality.

For more information and resources on optimizing your shipping processes, visit the Inbound Logistics Resources.