What Is a Stock Keeping Unit (SKU)?

If you're a business owner or involved in inventory management, you've likely come across the term Stock Keeping Unit (SKU). An SKU is a unique identification code assigned to a particular product, enabling businesses to track and manage their inventory effectively. According to a 2023 inventory management report, companies utilizing SKUs experience a 30% increase in inventory accuracy and a 25% reduction in carrying costs.

In this article, we'll explore the benefits of using SKUs, how they function, and strategies to create and manage an effective SKU system for your business.

Why Do You Need Stock Keeping Units (SKUs)?

SKUs are a cornerstone of effective inventory management. Without them, tracking stock levels, determining reorder points, and analyzing product performance can become daunting tasks. Implementing SKUs offers several advantages:

- Enhanced Inventory Accuracy: SKUs help maintain precise inventory counts, reducing discrepancies.

- Efficient Reordering: By monitoring SKU data, businesses can forecast demand and optimize reorder times.

- Performance Analysis: SKUs provide insights into which products are performing well, informing marketing and sales strategies.

Additionally, SKUs facilitate the management of bulk inventory, ensuring that businesses have a clear overview of products entering and leaving their warehouses.

For businesses selling product variations, such as different colors or sizes, SKUs enable the differentiation and tracking of each variant. This granularity assists in making informed decisions about restocking popular variations and discontinuing underperforming ones.

How Do SKUs Work?

SKUs are typically alphanumeric codes that uniquely identify each product. For example, a white t-shirt might have the SKU WT001, while a red dress could be labeled RD002. These codes are assigned when products are entered into an inventory management system, allowing for seamless tracking throughout the supply chain.

Beyond tracking inventory, SKUs play a vital role in sales data analysis. By monitoring sales based on SKU data, businesses can identify trends, understand customer preferences, and make data-driven decisions regarding inventory levels and product offerings.

Moreover, SKUs enhance order fulfillment accuracy. When a customer places an order, the corresponding SKU ensures the correct product is selected and shipped, minimizing errors and reducing the likelihood of returns or exchanges.

The Importance of SKUs in Inventory Management

Implementing SKUs streamlines inventory management processes by providing a clear understanding of stock levels. This clarity helps prevent overstocking or stockouts of popular products, optimizing inventory turnover rates.

Accurate inventory data, facilitated by SKUs, allows businesses to:

- Optimize Operations: Improved forecasting and inventory planning lead to more efficient operations.

- Enhance Supply Chain Efficiency: Clear SKU data ensures smooth coordination across the supply chain, from suppliers to customers.

- Inform Strategic Decisions: Insights derived from SKU data assist in making informed purchasing, pricing, and marketing decisions.

For businesses with diverse product lines or multiple locations, SKUs provide a consistent method for tracking and managing inventory, ensuring that all facets of the business are aligned and informed.

Different Types of SKUs

SKUs can vary in complexity based on business needs and product types. Common types include:

- Simple SKUs: Incorporate basic details like product number and color (e.g., BLK-T001 for a black t-shirt).

- Complex SKUs: Include additional information such as size, material, or specific product features (e.g., RD-DST-XL for a red dress with a specific design pattern in extra-large size).

- Location-Based SKUs: Encode information about the product's storage location within the warehouse.

Choosing the right SKU structure depends on factors like product diversity, inventory size, and operational complexity.

How to Create Effective SKUs for Your Business

Creating an effective SKU system starts with establishing a clear and consistent naming convention. Consider the following steps:

- Identify Relevant Attributes: Determine which product attributes are essential for identification, such as category, brand, size, color, and style.

- Develop a Logical Structure: Create a format that systematically incorporates the chosen attributes (e.g., Category-Brand-Size-Color).

- Ensure Uniqueness: Each SKU must be unique to avoid confusion, which can be achieved by combining letters and numbers specific to each product.

- Standardize Assignment: Implement a standardized process for assigning SKUs across the organization to maintain consistency.

- Regularly Review and Update: Periodically assess the SKU system to eliminate redundancies and incorporate new product variations.

For example, a standardized SKU for a medium-sized blue widget from Brand X could be WX-WG-MB, where "WX" denotes Brand X, "WG" stands for widget, "M" for medium, and "B" for blue.

Top Benefits of Using SKUs in Your Business

Utilizing SKUs offers benefits that extend beyond inventory management:

- Operational Efficiency: Streamlined processes reduce time spent on inventory tasks.

- Error Reduction: Accurate product identification minimizes mistakes in order fulfillment.

- Scalability: A robust SKU system supports business growth by accommodating increasing product lines and inventory volumes.

- Customer Insights: Tracking SKU data reveals customer purchasing patterns, aiding in targeted marketing and product development.

Businesses leveraging SKUs report up to a 20% improvement in operational efficiency and a significant decrease in order errors, according to industry studies.

Common Mistakes to Avoid When Implementing SKUs

Implementing a SKU system can present challenges if not approached thoughtfully. Common pitfalls include:

- Inconsistent Naming Conventions: Failing to establish and adhere to a standardized naming system leads to confusion and errors.

- Overcomplicating SKUs: Creating overly complex SKUs can make the system cumbersome and difficult to manage.

- Neglecting Regular Maintenance: Without periodic reviews, the SKU system can become outdated, leading to inaccurate inventory data.

- Insufficient Training: Lack of employee training on the SKU system results in inconsistent usage and data entry errors.

To avoid these mistakes, ensure clear guidelines are established, maintain simplicity where possible, regularly audit the SKU system, and provide comprehensive training to all relevant personnel.

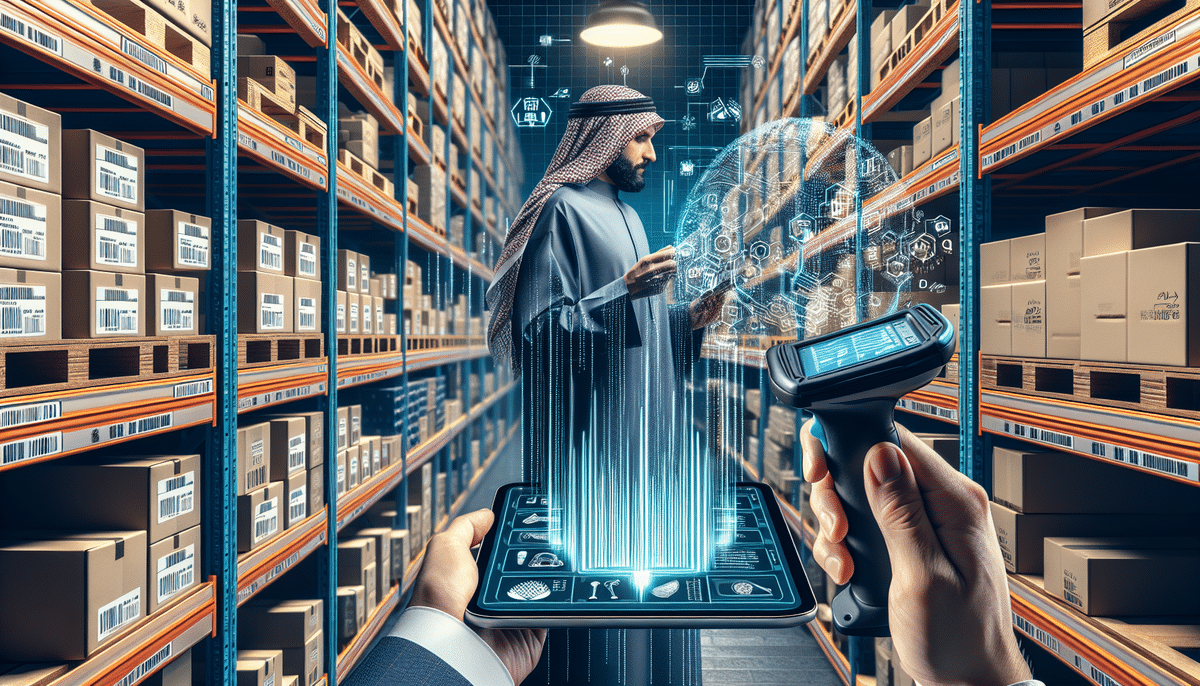

How Technology Is Changing the Use of SKUs

Advancements in technology are revolutionizing SKU management, making it more efficient and insightful:

- RFID Technology: Radio Frequency Identification (RFID) tags attached to products allow for real-time inventory tracking, enhancing accuracy and reducing manual errors.

- Machine Learning Algorithms: These algorithms analyze SKU-based sales data to predict future demand, helping businesses optimize inventory levels and reduce stockouts or overstock situations.

- Automated Inventory Systems: Integrating SKUs with automated inventory management systems streamlines data entry, tracking, and reporting processes.

- Cloud-Based Solutions: Cloud platforms enable seamless SKU management across multiple locations and channels, facilitating better collaboration and data accessibility.

According to a 2023 technology trends report, businesses adopting advanced SKU management technologies have seen a 35% improvement in inventory accuracy and a 40% increase in operational efficiency.

Integrating SKUs with POS and E-commerce Platforms

Modern Point of Sale (POS) systems and e-commerce platforms offer seamless integration with SKU systems, enhancing overall business operations:

- Unified Inventory Tracking: Integrating SKUs across POS and e-commerce platforms ensures real-time synchronization of inventory data, preventing overselling and stock discrepancies.

- Enhanced Customer Experience: Accurate SKU data enables faster and more reliable order processing, improving customer satisfaction.

- Data-Driven Insights: Integrated systems provide comprehensive analytics on sales performance, customer behavior, and inventory trends, informing strategic decisions.

For instance, when a sale occurs online, the integrated SKU system automatically updates inventory levels in the POS system, maintaining consistency across all sales channels.

Tips for Managing and Updating Your SKU System

Maintaining an effective SKU system requires continuous management and updates. Here are key tips to ensure its success:

- Establish Clear Naming Conventions: Create a logical and consistent naming structure that incorporates relevant product attributes.

- Regular Audits: Periodically review SKU data to identify and rectify duplicates, errors, or inconsistencies.

- Leverage Automation: Utilize inventory management software to automate SKU assignments and tracking, reducing manual workload and errors.

- Employee Training: Ensure all team members understand the SKU system and are trained on proper usage and data entry protocols.

- Integrate with Other Systems: Link your SKU system with other business tools like CRM, ERP, and supply chain management systems for cohesive operations.

Implementing these practices will help maintain an accurate and efficient SKU system, supporting overall business growth and operational excellence.

Understanding the Role of SKUs in Supply Chain Management

Effective supply chain management relies heavily on the transparency and oversight provided by SKUs. By assigning unique SKUs to each product, businesses can:

- Track Products Throughout the Supply Chain: Monitor products from suppliers to warehouses and ultimately to customers, ensuring seamless movement and reducing the risk of lost shipments.

- Enhance Coordination: Facilitate better communication and coordination between different stages of the supply chain, improving efficiency and reducing delays.

- Improve Forecasting: Utilize SKU data to predict demand trends, enabling proactive inventory and supply chain adjustments.

According to supply chain experts, integrating SKUs into supply chain management can lead to a 20% improvement in delivery times and a 15% reduction in logistics costs.

By leveraging SKUs, businesses can ensure accuracy in order fulfillment, reduce errors, and enhance overall customer satisfaction.

Challenges of Implementing an Effective SKU System

Implementing a robust SKU system comes with its set of challenges, including:

- Initial Setup Complexity: Designing a comprehensive SKU system that accommodates all product variations requires thorough planning and analysis.

- Consistency Enforcement: Ensuring that all team members adhere to the established SKU naming conventions can be difficult, especially in larger organizations.

- System Integration: Integrating SKUs with existing business systems (e.g., ERP, CRM) may involve technical complexities and require specialized expertise.

- Scalability Issues: As the product line expands, the SKU system must be scalable to handle increased complexity without compromising accuracy.

Addressing these challenges involves strategic planning, investing in the right technology, and fostering a culture of consistency and accuracy within the organization.

Best Practices for Using SKUs in Retail and Wholesale Settings

Whether operating in retail or wholesale, adhering to best practices for SKU management ensures optimal performance and efficiency:

- Define Clear Objectives: Understand what you aim to achieve with your SKU system, such as improved inventory accuracy or enhanced sales tracking.

- Standardize Naming Conventions: Develop a consistent SKU format that reflects key product attributes and facilitates easy identification.

- Train Employees Thoroughly: Provide comprehensive training to all employees on the importance of SKUs and proper data entry methods.

- Utilize Advanced Technology: Invest in modern inventory management systems that support advanced SKU functionalities and integrations.

- Monitor and Adjust: Continuously monitor SKU performance and make necessary adjustments to accommodate new products or changing market demands.

Implementing these best practices can lead to significant improvements in inventory management, sales tracking, and overall operational efficiency.

Conclusion: Why Every Business Needs a Good SKU System in Place

At the core of any successful business lies a robust inventory management system, which hinges on the effective use of SKUs. By accurately tracking and managing product data through SKUs, businesses can make informed decisions, optimize operations, and scale efficiently.

Implementing a well-structured SKU system enhances inventory accuracy, streamlines supply chain processes, and provides valuable insights into sales and customer behavior. These advantages not only improve operational efficiency but also contribute to increased sales and customer satisfaction.

In an increasingly competitive market, a good SKU system is indispensable for maintaining organization, reducing errors, and supporting sustainable business growth.