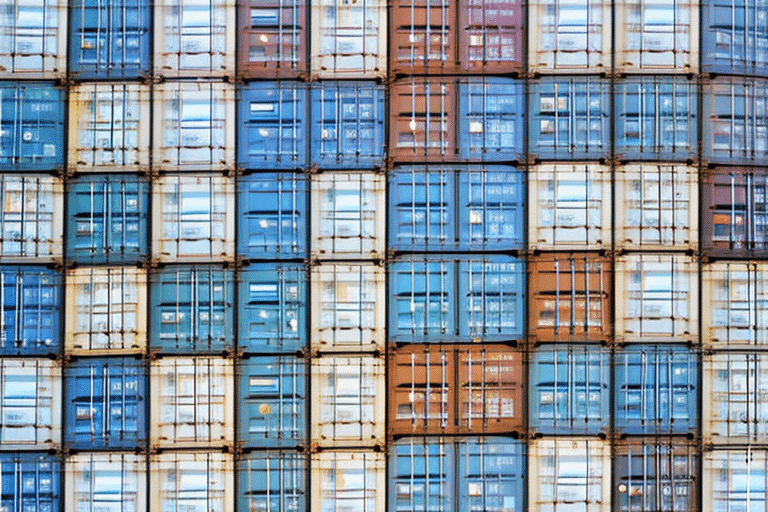

What Is Dunnage? Understanding Its Critical Role in Shipping

If you work in the shipping and logistics industry, you have likely encountered the term "dunnage" before. Dunnage refers to a variety of materials used in shipping to protect cargo during transit. This comprehensive guide explores the purpose and benefits of dunnage, the different types of materials used, how to choose the right dunnage for your needs, and best practices for storage and handling. Additionally, we will discuss the role of dunnage in ensuring product safety during transit, innovations in dunnage material technology, and common challenges with solutions.

The Purpose of Dunnage in Shipping and Logistics

The primary purpose of dunnage is to prevent damage to cargo during transit. Cargo is often exposed to the elements and can shift within the cargo hold, potentially damaging fragile items or those not secured properly. Dunnage materials provide a physical barrier between cargo items or between cargo and the walls of the cargo hold. Additionally, dunnage absorbs shock or vibration during transit, further protecting the cargo.

Another critical function of dunnage is compliance with regulations and safety standards. Certain types of cargo require specific dunnage to meet safety regulations, such as separating hazardous materials from other cargo to prevent accidents or contamination.

Moreover, dunnage optimizes space utilization in cargo holds. By creating compartments or securing cargo in specific areas, shippers can maximize the amount of cargo transported in a single shipment, leading to cost savings and increased efficiency.

Key Benefits of Dunnage

- Prevents cargo shifting and damage

- Absorbs shock and vibration

- Ensures compliance with safety regulations

- Optimizes space utilization in cargo holds

Types of Dunnage Materials Used in Shipping

Various materials serve as dunnage, each suited to different shipping needs:

- Wood: Ideal for heavy items or those requiring a sturdy base.

- Plastic: Lightweight and flexible, suitable for irregularly shaped items.

- Paper: Lightweight and often used for void fill.

- Foam: Soft and moldable, protecting delicate items effectively.

The choice of dunnage material also depends on environmental factors. For instance, wood dunnage may be restricted in certain countries to prevent pest spread, necessitating alternatives like plastic or paper. Additionally, companies are increasingly opting for recyclable or biodegradable materials to minimize environmental impact.

Eco-Friendly Dunnage Options

With growing environmental concerns, sustainable dunnage options are gaining popularity:

- Biodegradable Foam: Breaks down naturally, reducing environmental footprint.

- Recycled Paper: Utilizes recycled materials, promoting sustainability.

- Reusable Plastic: Durable and can be used multiple times, lowering long-term costs.

According to a 2020 study published in the Journal of Cleaner Production, sustainable dunnage materials significantly reduce the environmental impact of shipping operations.

Choosing the Right Dunnage for Your Shipping Needs

Selecting the appropriate dunnage is crucial for the safe transportation of cargo. Key factors to consider include:

- Weight and Fragility: Heavier and more fragile items may require sturdier dunnage like wood or reinforced foam.

- Size and Shape: Irregularly shaped items benefit from flexible materials like plastic or foam that can conform to their form.

- Mode of Transportation: Air, sea, and land transport have different requirements for dunnage based on handling and environmental exposure.

- Environmental Conditions: Extreme temperatures or high humidity may necessitate moisture-resistant dunnage.

Consulting with shipping experts can help determine the most appropriate dunnage material and configuration for your specific cargo shipment.

Cost-effectiveness is also a significant consideration. Balancing protection levels with material costs ensures that the shipping process remains economically viable without compromising cargo safety.

Assessing Environmental Impact

When selecting dunnage, it's essential to consider the environmental conditions the cargo will encounter:

- Temperature Extremes: Use materials that can withstand high or low temperatures.

- Humidity Levels: Moisture-resistant dunnage prevents damage in high humidity environments.

- Vibration and Shock: Enhanced cushioning materials protect sensitive equipment and fragile items.

Data from the International Air Transport Association (IATA) highlights the importance of selecting appropriate dunnage to mitigate cargo damage during various transport conditions.

Best Practices for Storing and Handling Dunnage Materials

Proper storage and handling of dunnage ensure its effectiveness in protecting cargo:

- Storage Conditions: Keep dunnage in clean, dry, and well-ventilated areas to prevent moisture buildup and deterioration.

- Handling Procedures: Handle dunnage with care to avoid damage or deformation, maintaining its protective qualities.

- Regular Inspections: Inspect dunnage for signs of wear or damage and replace as necessary to ensure ongoing protection.

- Weight Management: Follow weight capacity guidelines to prevent overloading storage areas, which can damage dunnage and reduce its efficacy.

- Organization and Labeling: Properly label and organize dunnage materials for easy identification and access, facilitating efficient inventory management.

Implementing these best practices extends the lifespan of dunnage materials and ensures they perform optimally when needed.

Implementing Effective Inventory Management

Efficient inventory management of dunnage materials involves:

- Labeling Systems: Use clear labels to identify different types of dunnage quickly.

- Storage Solutions: Utilize shelving and storage containers to organize dunnage systematically.

- Tracking Usage: Monitor dunnage usage to anticipate replacement needs and maintain adequate stock levels.

Research from the Logistics Management journal emphasizes the importance of organized inventory systems in reducing waste and improving operational efficiency.

The Role of Dunnage in Ensuring Product Safety During Transit

Dunnage is pivotal in maintaining product safety throughout the shipping process. By acting as a physical barrier and absorbing shocks, dunnage prevents damage to fragile or irregularly shaped items. Properly secured dunnage also minimizes the risk of cargo shifting, which can lead to collisions or breakage during transit.

Different types of dunnage materials—such as wood, foam, and airbags—are chosen based on the specific needs of the cargo, including weight, fragility, and transportation mode. For example, foam dunnage is ideal for delicate electronics, while wood is better suited for heavy machinery.

Efficient use of dunnage not only protects the cargo but also enhances the overall shipping process by reducing loading and unloading times and minimizing delays caused by damaged goods. According to the U.S. Department of Transportation, effective dunnage usage is essential for ensuring the integrity and safety of transported goods.

Innovations in Dunnage Design and Material Technology

Recent advancements in dunnage design and material technology have significantly improved shipping efficiency. Manufacturers are developing new materials that are lighter, stronger, and more durable than traditional options. Additionally, innovative designs allow for more efficient use of cargo space, maximizing transportation capacity and reducing costs.

One of the most notable innovations is the incorporation of 3D printing technology in dunnage design. This technology enables the creation of custom dunnage solutions tailored to the specific dimensions and requirements of each shipment, enhancing protection and optimizing space utilization.

Another significant development is the use of eco-friendly materials. Manufacturers are increasingly using biodegradable and recyclable materials made from renewable resources, aligning with sustainability goals and reducing the environmental impact of shipping operations. A study by ScienceDirect highlights the effectiveness of eco-friendly dunnage in reducing carbon footprints while maintaining cargo protection standards.

Adoption of Smart Dunnage Solutions

Smart dunnage solutions incorporate technology to enhance monitoring and protection of cargo:

- Sensor-Integrated Dunnage: Embedding sensors to monitor temperature, humidity, and shock during transit.

- Reusable Dunnage Systems: Designed for multiple uses, reducing waste and long-term costs.

These innovations not only improve cargo safety but also provide valuable data for optimizing shipping processes.

Overcoming Common Challenges with Dunnage

Working with dunnage presents several challenges, including selecting the appropriate material and configuration for specific cargo shipments. Improper securing or handling of dunnage can lead to cargo and transportation vehicle damage. To address these challenges:

- Consult Shipping Experts: Engaging with professionals can ensure the right dunnage materials and configurations are selected.

- Training Staff: Proper training on dunnage handling and securing techniques can prevent accidental damage.

- Regular Inspections: Frequent checks during transportation can identify and address issues promptly.

- Invest in Quality Materials: Using high-quality dunnage reduces the likelihood of failure during transit.

Implementing these strategies can mitigate risks associated with dunnage usage, ensuring safe and efficient cargo transportation.

In conclusion, dunnage is an essential component of shipping and logistics operations. By providing a physical barrier and absorbing shock and vibration, dunnage helps prevent damage to fragile cargo items and ensures the safe transportation of goods. Proper selection, securing, and handling of dunnage materials are crucial for their effectiveness. Additionally, advancements in dunnage technology and sustainable practices are enhancing the efficiency and environmental sustainability of shipping operations.