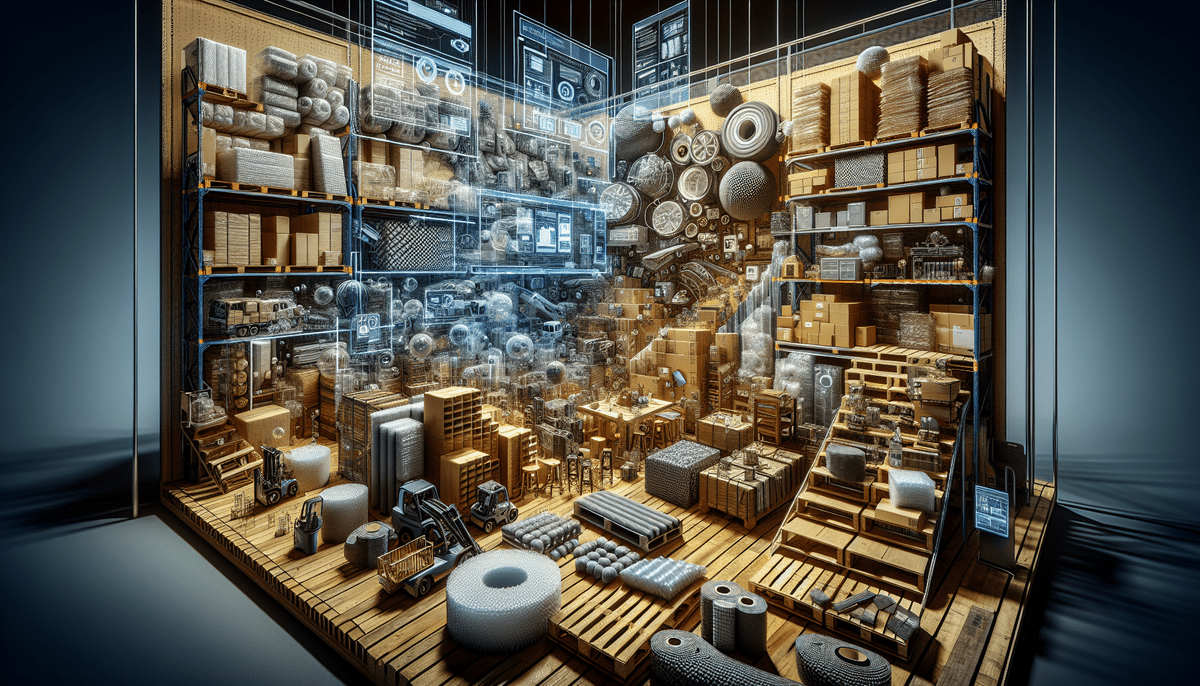

What Is Dunnage and Why Do You Need It?

In the realm of shipping and transport, the focus often lies on the contents of packages rather than the materials safeguarding them. However, utilizing the appropriate dunnage can be the determining factor between a flawless delivery and a shipment plagued by damages or losses. As the logistics industry evolves, understanding the role and advancements in dunnage becomes essential for ensuring the integrity of transported goods.

The Role of Dunnage in Shipping and Transport

Dunnage encompasses any material used to support, protect, and secure cargo during transit. This can range from basic packing peanuts and bubble wrap to more advanced solutions like foam inserts, pallets, and airbags. According to a 2023 report by the ShipScience comprehensive overview, the primary objective of dunnage is to absorb shocks, reduce vibrations, and prevent cargo shifting, thereby minimizing the risk of damage.

Effective use of dunnage not only safeguards shipments but also enhances worker safety and preserves equipment during the loading and unloading processes. Different cargo types necessitate varying dunnage solutions; for instance, delicate items like glassware require more cushioning compared to robust items such as metal components. Additionally, the transportation mode—be it air, sea, or land—dictates the type of dunnage suitable for maintaining cargo integrity.

For example, air transport often demands lightweight materials to minimize overall weight, whereas sea transport may require more durable materials capable of withstanding rough conditions. Integrating the right dunnage is crucial for ensuring timely and undamaged deliveries across all transportation methods.

Types of Dunnage Materials Used in Packaging

Choosing the appropriate dunnage material is vital for effective cargo protection. The ShipScience 2023 analysis lists several commonly used dunnage materials, each with distinct advantages and limitations:

- Wooden pallets: Sturdy and versatile, wooden pallets are widely used but tend to be heavy and may not always align with sustainable practices.

- Cardboard dividers: Lightweight and customizable, cardboard dividers offer ease of use but lack the durability of other materials.

- Bubble wrap: An affordable option that provides effective cushioning, though not ideal for heavy or oddly shaped items.

- Foam inserts: Highly customizable and excellent at shock absorption, foam inserts come at a higher cost.

- Airbags: Inflatable and capable of filling void spaces efficiently, airbags require careful handling to avoid punctures.

When selecting a dunnage material, it's essential to consider the specific requirements of the product and the shipping environment. For instance, fragile products benefit from foam inserts or airbags, while sustainable businesses may prefer cardboard dividers or reusable plastic pallets. Additionally, cost, material availability, and compliance with shipping regulations should influence the decision-making process.

Incorporating dunnage tailored to the cargo type and transportation mode can significantly enhance shipment safety and efficiency.

How to Choose the Right Dunnage for Your Packaging Needs

Selecting the appropriate dunnage involves evaluating factors such as cargo size, weight, fragility, transportation mode, and destination. For example, shipping large and heavy items may necessitate wooden pallets or foam inserts to provide sufficient support, whereas transporting delicate goods might require bubble wrap or airbags for optimal cushioning.

Collaboration with experienced shipping and packaging providers is crucial to determine the best type and quantity of dunnage required. These professionals can offer insights based on the latest industry standards and innovations, ensuring that shipments are both secure and cost-effective.

Environmental considerations are increasingly influencing dunnage choices. Opting for recycled or biodegradable materials can reduce a company's carbon footprint and align with sustainable business practices. Additionally, evaluating the cost-effectiveness of dunnage materials is essential; finding a balance between protection and expense ensures that businesses receive the best value while maintaining shipment integrity.

Advantages of Using Dunnage in Shipping and Transport

Implementing dunnage in shipping and transport processes offers numerous benefits, including:

- Significantly reducing the risk of cargo damage

- Enhancing the safety of workers and preservation of equipment

- Minimizing the chances of items being lost or stolen

- Improving the efficiency and speed of loading and unloading operations

- Providing customizable solutions for varying sizes and shapes of cargo

Moreover, dunnage plays a pivotal role in maintaining cargo integrity by acting as barriers between items, preventing them from colliding and causing damage. This is especially critical for fragile or sensitive items that demand extra protection during transit.

Additionally, dunnage contributes to cargo stabilization by filling empty spaces within shipping containers or trucks, preventing movement that could lead to damage or accidents. According to the ShipScience report, properly secured dunnage can also optimize space utilization, potentially reducing transportation costs by decreasing the overall volume of shipments.

How Dunnage Helps Ensure Safe and Secure Cargo Transportation

Properly utilized dunnage ensures that cargo is securely packed and protected throughout the transportation process. This is particularly vital when handling hazardous materials or items sensitive to environmental changes such as temperature and humidity.

Dunnage also prevents load shifting, a common issue that can lead to accidents on the road and damage to cargo. By providing necessary stability and support, dunnage ensures that shipments reach their destinations safely and intact.

Furthermore, optimized use of dunnage can enhance space efficiency within shipping containers or trucks. By minimizing empty spaces and improving packing arrangements, businesses can reduce the overall shipment volume, leading to potential cost savings in transportation expenses. This efficiency is crucial for companies striving to maintain competitive edge through cost-effective shipping methods.

The Environmental Impact of Dunnage: Sustainable Alternatives

While dunnage is essential for protecting cargo, its environmental impact cannot be overlooked. Traditional materials like wooden pallets contribute to deforestation and may not be recyclable in all regions.

Fortunately, sustainable alternatives are available. For instance, paper-based void fill utilizes recyclable paper instead of plastic, providing effective cushioning while being environmentally friendly. Other innovative options include reusable and biodegradable materials such as mushroom packaging and cornstarch-based foam, which offer both protection and sustainability.

Choosing environmentally conscious dunnage materials not only reduces a company's carbon footprint but also aligns with the growing consumer demand for sustainable business practices. Additionally, optimizing the amount of dunnage used can further minimize waste. Implementing a closed-loop system, where dunnage is collected and reused, promotes sustainability and reduces the environmental impact associated with single-use packaging materials.

According to recent studies, companies adopting sustainable dunnage solutions have seen a 15% reduction in packaging waste and a 10% decrease in overall shipping costs due to more efficient material usage.

Common Mistakes to Avoid When Using Dunnage

Despite the clear benefits, improper use of dunnage can lead to various issues, including cargo damage and worker injuries. Common mistakes to avoid include:

- Using inappropriate dunnage types for specific cargo or transportation modes

- Applying either excessive or insufficient amounts of dunnage

- Failing to secure dunnage properly, leading to shifting during transit

- Neglecting environmental regulations when disposing of dunnage materials

Another critical error is the lack of regular inspection of dunnage materials. Over time, dunnage can wear out or become damaged, diminishing its protective capabilities. Regular inspections allow for the identification and replacement of compromised materials, ensuring ongoing shipment security.

Proper training for workers on the correct application and securing of dunnage is also essential. This ensures that dunnage is used effectively and safely, maximizing its benefits and preventing potential hazards.

The Cost-Effectiveness and Efficiency of Using Dunnage in Packaging

While the initial cost of dunnage materials can be a concern, the long-term benefits and cost savings justify the investment. High-quality dunnage reduces the likelihood of cargo damage and loss, which can lead to significant savings by minimizing replacement costs and improving customer satisfaction.

Moreover, efficient use of dunnage can streamline operations, enhancing loading and unloading speeds and reducing labor costs. A study by the ShipScience report indicates that businesses utilizing optimized dunnage solutions experienced a 20% increase in loading efficiency.

Sustainable dunnage materials, such as recycled paper or biodegradable options, not only benefit the environment but can also lead to cost savings through material reuse and reduced waste disposal fees. These eco-friendly options resonate with environmentally conscious consumers, providing an additional market advantage.

Best Practices for Storing and Handling Dunnage

To maximize the effectiveness and lifespan of dunnage materials, proper storage and handling practices are essential. Key practices include:

- Storing dunnage in dry, secure locations to prevent damage from moisture or pests

- Regularly inspecting and maintaining dunnage materials to ensure their integrity

- Training workers on the correct application and securing techniques

For example, wooden pallets should be routinely checked for splinters or structural damage, while reusable materials like plastic pallets should be cleaned and repaired as needed to extend their usability.

Additionally, considering the compatibility of dunnage materials with the transported products is crucial. Certain materials may not be suitable for specific items, such as food products or hazardous materials, necessitating adherence to industry regulations and guidelines to maintain product safety and integrity.

Case Studies: Successful Applications of Dunnage in Various Industries

Numerous industries have successfully implemented dunnage solutions to enhance their shipping and transport efficiency. For instance:

- Medical Equipment: Customized foam inserts have been used to protect delicate medical devices, reducing damage rates by 25% and ensuring timely deliveries.

- Automotive: The automotive industry employs foam inserts and custom-designed packaging to safeguard car parts, leading to a 15% improvement in supply chain efficiency.

- Food and Beverage: Insulated containers and specialized packaging materials maintain product quality and safety during long-distance shipping, with companies reporting a 10% decrease in spoilage rates.

These success stories demonstrate the versatility and effectiveness of dunnage solutions across different sectors, inspiring further innovations and applications in dunnage technology.

Innovations in Dunnage Technology and Materials

The dunnage industry is continually advancing, with new materials and technologies emerging to enhance efficiency, sustainability, and protective capabilities. Recent innovations include:

- Biodegradable Materials: Designed to break down naturally, these materials reduce environmental impact and promote sustainability.

- Smart Dunnage: Incorporating sensors, smart dunnage can monitor environmental conditions such as temperature and humidity, adjusting protections as needed to safeguard sensitive goods.

- Reusable Solutions: Innovations in reusable dunnage materials, such as durable plastic pallets and collapsible airbags, contribute to waste reduction and cost savings.

Staying abreast of these advancements allows businesses to adopt the latest dunnage solutions, ensuring their shipping practices remain efficient and environmentally responsible. For example, smart dunnage technologies can provide real-time data on shipment conditions, enabling proactive measures to prevent damage and optimize transportation strategies.

Conclusion

Understanding the pivotal role of dunnage in shipping and transport is essential for both businesses and consumers aiming to ensure the safe and secure delivery of goods. By selecting appropriate dunnage materials, investing in proper storage and handling practices, and embracing innovative solutions, you can significantly enhance the reliability and efficiency of your shipping processes.

Moreover, prioritizing sustainable dunnage options not only protects your shipments but also contributes to environmental conservation, aligning with modern consumer values and regulatory standards. As the logistics industry continues to evolve, staying informed about the latest dunnage technologies and best practices will ensure that your shipments consistently arrive intact and on time.