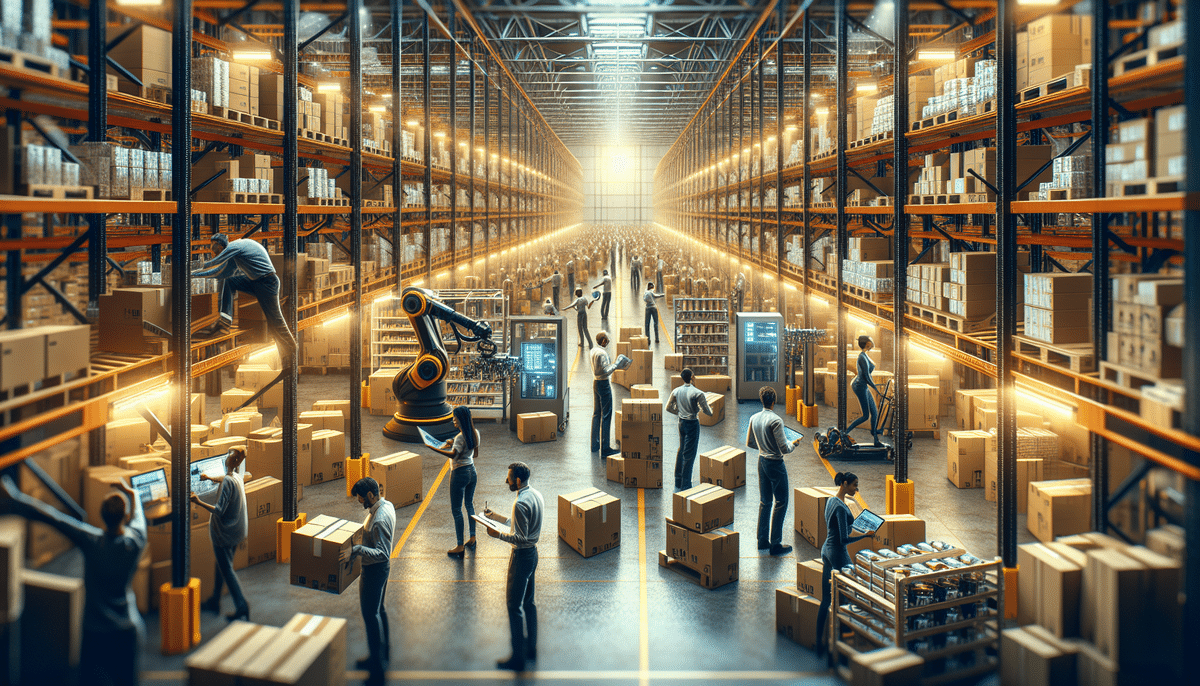

What Is Kitting Logistics? A Definition and Explanation

Kitting logistics is a strategic technique used in supply chain management that involves gathering and organizing individual items into kits or packages for efficient delivery and production. This approach requires careful consideration of inventory management, assembly methods, and the overall logistics process to maximize efficiency and minimize costs. In this article, we explore the importance of kitting logistics in supply chain management, its top benefits, various kitting logistics techniques, and how it helps in reducing costs and improving operational efficiency.

The Importance of Kitting Logistics in Supply Chain Management

Kitting logistics plays a crucial role in supply chain management by streamlining the production and delivery of goods. It ensures that all necessary parts and materials are readily available for production and assembly, reducing the time and effort required to retrieve and gather materials. This optimization can lead to a 15% increase in productivity, according to industry reports.

Additionally, kitting logistics allows for greater flexibility and scalability in the supply chain by enabling businesses to quickly adapt to changes in demand and production requirements. By having kits that contain all necessary components readily available, companies can respond more swiftly to fluctuations in demand, reducing the risk of costly delays and enhancing customer satisfaction.

Another significant benefit of kitting logistics is its ability to reduce waste and minimize inventory costs. By pre-assembling kits of materials and components, businesses can avoid over-ordering or under-ordering parts, which can lead to excess inventory or stockouts. This optimization can result in up to 20% cost savings for businesses by maintaining optimal inventory levels and reducing waste.

Furthermore, kitting logistics can improve the accuracy and quality of the final product. By ensuring that all necessary parts and materials are included in each kit, businesses can reduce the risk of errors or defects in the production process. This leads to higher quality products and fewer returns or customer complaints, ultimately enhancing the reputation and profitability of the business.

Top Benefits of Implementing Kitting Logistics

Implementing kitting logistics techniques in your business offers numerous benefits, including:

- Improved Efficiency: By having all necessary materials readily available, kitting logistics reduces the time and effort required to gather and assemble materials for production and delivery.

- Cost Savings: Kitting logistics can help companies save costs by reducing inventory, minimizing waste and scrap, and optimizing pack sizes.

- Increased Scalability: With kitting logistics, companies can more easily and quickly scale their operations up or down in response to changes in demand or production requirements.

- Enhanced Quality Control: Kitting logistics ensures that all necessary materials and components are properly accounted for, reducing the risk of errors and defects.

Additionally, implementing kitting logistics can significantly improve customer satisfaction. By having all necessary materials and components readily available, companies can fulfill customer orders more quickly and efficiently, reducing lead times and enhancing delivery times. This can lead to increased customer loyalty and positive word-of-mouth recommendations.

Different Types of Kitting Logistics Techniques

Businesses can implement several kitting logistics techniques to optimize their supply chain:

- Traditional Kitting: Manually assembling and packaging different components into kits or packages.

- Pre-Kitting: Assembling kits in advance and storing them in inventory until needed.

- Dynamic Kitting: Assembling kits based on current demand, allowing for greater flexibility in the supply chain.

- Backward Kitting: Collecting and assembling components in reverse order, starting with the final assembly and working backwards.

Another innovative kitting logistics technique is Virtual Kitting. This method involves assembling kits virtually using software and digital tools rather than physically assembling them. Virtual kitting enhances efficiency and accuracy in the kitting process and reduces the need for physical storage space. It can be combined with other kitting techniques, such as pre-kitting or dynamic kitting, to further optimize the supply chain.

How Kitting Logistics Helps in Reducing Costs and Improving Efficiency

Kitting logistics reduces the time and effort required to gather and assemble materials, helping businesses save on costs and improve operational efficiency. By optimizing pack sizes and minimizing waste and scrap, kitting logistics techniques can significantly reduce inventory requirements.

With kitting logistics, businesses can enhance quality control by ensuring that all necessary materials and components are properly accounted for and assembled. This reduces the risk of errors and defects, leading to higher customer satisfaction and fewer returns or repairs.

Moreover, kitting logistics streamlines supply chain management by pre-assembling kits of materials and components. This reduces the number of suppliers businesses need to engage with and simplifies procurement processes, thereby decreasing lead times and enhancing overall supply chain efficiency.

Additionally, kitting logistics enables businesses to respond more quickly to changes in demand. Having pre-assembled kits allows companies to adjust their production schedules rapidly in response to shifts in customer orders, helping them stay agile and competitive in a dynamic market.

A Step-by-Step Guide to Implementing Kitting Logistics in Your Business

If you're interested in implementing kitting logistics in your business, follow this step-by-step guide:

- Identify your inventory requirements and determine the components that need to be assembled into kits.

- Choose the best kitting logistics technique that aligns with your business needs.

- Source the necessary components and materials from reliable suppliers.

- Assemble the kits or packages according to the selected kitting method.

- Store the assembled kits in inventory until they are needed for production or delivery.

- Implement a robust system to track inventory levels and monitor demand trends.

- Regularly adjust inventory levels and assembly processes to optimize efficiency and reduce costs.

By following this step-by-step guide, you can successfully implement kitting logistics in your business, leading to reduced assembly time, minimized errors, improved operational efficiency, better inventory management, and reduced waste. These improvements will help your business operate more smoothly and cost-effectively.

Common Challenges Faced in Kitting Logistics and How to Overcome Them

While kitting logistics offers significant benefits, businesses may encounter several common challenges:

- Difficulty in Sourcing Materials: Finding the necessary components and materials for kits can be challenging.

- Inventory Management Issues: Without proper tracking and monitoring, businesses may face inventory shortages or overstocks.

- Assembly and Packaging Errors: Improper execution can lead to errors and defects in the final products.

To overcome these challenges, businesses should:

- Implement effective inventory management systems to accurately track and monitor stock levels.

- Collaborate closely with suppliers to ensure timely and accurate delivery of materials.

- Invest in quality control measures to ensure that all kits are properly assembled and packaged.

Another challenge is the need for customization. Customers may have specific requirements for components and materials included in their kits, which can complicate sourcing and assembly processes. To address this, businesses should establish flexible kitting systems that can accommodate customization requests efficiently.

External factors such as weather, transportation delays, and supply chain disruptions can also impact kitting logistics. Businesses should develop contingency plans to address these issues and minimize their impact on operations.

Real-life Examples of Successful Implementation of Kitting Logistics

Several industries have successfully implemented kitting logistics to enhance their operations:

- Automotive Industry: Car manufacturers use kitting logistics to streamline production and improve efficiency. By having all necessary components and materials readily available in kits, they can quickly assemble and produce high-quality vehicles.

- E-commerce Industry: Online retailers utilize kitting logistics to prepare orders for shipment. By assembling multiple items from a single order into a single package or kit, they can reduce shipping costs and improve delivery times.

- Healthcare Industry: Hospitals and clinics use kitting logistics to ensure that medical supplies and equipment are readily available for patient care. Having all necessary items in one kit allows healthcare professionals to attend to patients quickly and efficiently.

- Aerospace Industry: Aircraft manufacturers employ kitting logistics to ensure that all necessary components are available for assembly. This reduces production time and enhances the overall quality of the aircraft.

Future Trends and Innovations in Kitting Logistics

The future of kitting logistics is set to be shaped by several promising innovations and technological advancements:

- Automation and Robotics: The use of automation and robotics can significantly improve the assembly process and reduce labor costs, making kitting logistics more efficient.

- Data Analytics and Machine Learning: Leveraging data analytics and machine learning can enhance inventory management and demand forecasting capabilities, leading to greater efficiency and cost savings.

- Sustainable Practices: Increasing environmental awareness is driving companies to adopt sustainable practices in kitting logistics. This includes using eco-friendly packaging materials, optimizing transportation routes to reduce emissions, and implementing recycling programs. Prioritizing sustainability not only helps reduce the environmental impact but also appeals to environmentally conscious consumers.

These trends indicate that kitting logistics will continue to evolve, offering businesses more efficient, cost-effective, and sustainable solutions for their supply chain needs.

Choosing the Right Provider for Your Kitting Logistics Needs

Selecting the right provider for your kitting logistics needs is crucial for ensuring smooth operations. Consider the following factors when making your decision:

- Cost: Evaluate the pricing structure and ensure it aligns with your budget without compromising quality.

- Reliability: Choose a provider with a proven track record of reliability and consistency in delivering services.

- Quality: Assess the provider’s quality control processes to ensure they meet your standards.

- Industry Experience: Opt for a provider with experience in your specific industry, as they will better understand your unique requirements.

- Customization Capabilities: Ensure the provider can handle customization requests, such as unique packaging or labeling, to meet your specific needs.

- Customer Service: Good customer service is essential. Look for a provider who assigns a dedicated account manager to your business, providing a single point of contact for any questions or concerns.

By carefully evaluating these factors, you can select a kitting logistics provider that not only meets your current needs but also supports your business as it grows and evolves.

Conclusion

Kitting logistics is a valuable technique for businesses across various industries. By streamlining production and delivery processes, it enhances efficiency, reduces costs, and boosts customer satisfaction. Selecting the right kitting logistics provider and implementing appropriate techniques can help businesses stay competitive and thrive in today’s fast-paced and constantly evolving market. Embracing kitting logistics is a strategic move that can lead to significant operational improvements and long-term success.