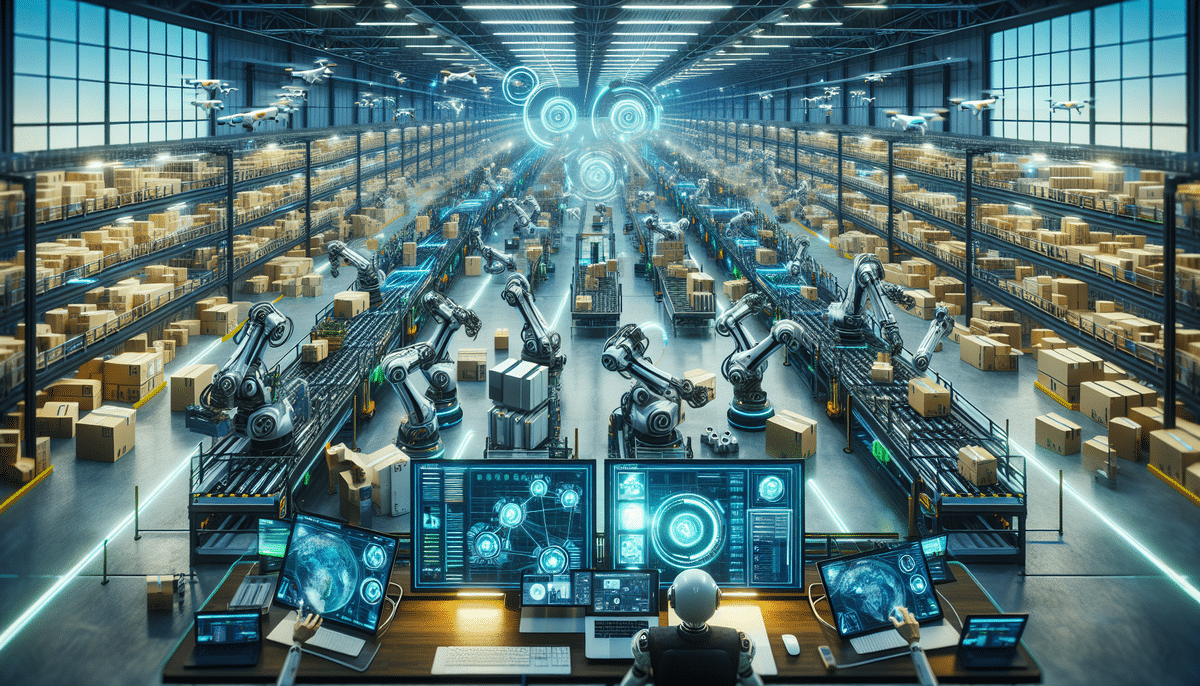

What Is Pick-to-Box? An Overview of This Automated Warehouse System

If you run an e-commerce or retail business, you understand the importance of having an efficient inventory management system. One popular option for automated warehouse operations is Pick-to-Box. This system has gained traction in recent years due to its ability to enhance efficiency and reduce order processing times. In this article, we'll explore what Pick-to-Box is, how it works, and the benefits and challenges of implementing it in your operations.

How Pick-to-Box Works: A Detailed Explanation of the System

Pick-to-Box is an automated warehouse system that utilizes robotic technology to retrieve items from their storage locations and place them directly into their designated shipping boxes. The technology behind Pick-to-Box includes conveyors, automated storage and retrieval systems (ASRS), and robotic arms or grippers. Essentially, the system operates through a warehouse management system (WMS) that directs orders to the correct storage locations. The Pick-to-Box technology then places the items directly into their assigned shipping boxes, reducing the time taken to pick items individually and saving space by eliminating the need for separate storage for shipping boxes.

One of the key benefits of Pick-to-Box is its accuracy. The system is designed to minimize errors in the picking process, as the robotic technology ensures that the correct item is selected and placed in the correct shipping box. This reduces the likelihood of incorrect orders being shipped, saving businesses both time and money.

Another advantage of Pick-to-Box is its scalability. The system can be easily expanded or modified to accommodate changes in order volume or product mix, making it a flexible solution for businesses that experience fluctuations in demand or need to adapt to changing market conditions.

Benefits of Pick-to-Box: Why This Automated Warehouse System is Gaining Popularity

The primary benefits of Pick-to-Box include improved efficiency, enhanced accuracy, and reduced order processing times. By using robotic technology to handle the picking and packing of items, Pick-to-Box eliminates the need for human workers to pick items manually. This not only reduces the risk of errors but also frees up labor resources to focus on tasks that require human intelligence.

Additionally, Pick-to-Box reduces the amount of space required for storage and operations. Since the system places items directly into their designated shipping boxes, there is no need for extra space to store shipping boxes. This also reduces the need for additional staff to handle packing and shipping tasks, thereby further improving efficiency and reducing costs.

Pick-to-Box also offers improved inventory management. The system tracks inventory levels in real-time, allowing for better control and accuracy in stock management. This helps prevent overstocking or understocking of items, which can lead to lost sales or excess inventory costs.

Furthermore, Pick-to-Box can be seamlessly integrated with other warehouse management systems, such as order management and shipping software. This integration ensures smooth communication between different systems, reducing the risk of errors and enhancing overall efficiency.

The History of Pick-to-Box and Its Evolution Over Time

Pick-to-Box is not a new concept in the realm of automated warehouse systems. It has been around for decades and has evolved to adapt to changing technologies and market demands. The earliest versions of Pick-to-Box relied heavily on manual labor to pick and pack items, with technology limited to light-duty applications. Over time, advancements in robotic technology and warehouse management software have made Pick-to-Box systems more robust and adaptable, enabling them to handle a wide range of products and order volumes.

In recent years, Pick-to-Box has become increasingly popular due to the rise of e-commerce and the need for faster and more efficient order fulfillment. According to a Forbes report, implementing automated systems like Pick-to-Box can increase order fulfillment efficiency by up to 30%.

As technology continues to advance, further improvements in Pick-to-Box systems are expected. Innovations such as drone-assisted picking and augmented reality technology are being explored to enhance accuracy and efficiency. With these developments, Pick-to-Box is poised to remain a vital component of automated warehouse systems for years to come.

Components of a Pick-to-Box System: Understanding the Technology Behind It

A typical Pick-to-Box system consists of several key components:

- Warehouse Management System (WMS): Manages the flow of orders through the system.

- Picking Robots: Utilize robotic arms or grippers to pick and place items into designated shipping boxes.

- Conveyors and ASRS: Transport items to the picking stations and store them until needed.

- Auxiliary Components: Include barcode scanners, computer systems, and printers that support the overall operation.

The software controlling the Pick-to-Box system is crucial. It manages order flows, optimizes picking routes, and ensures accurate placement of items. Additionally, it provides real-time data on order statuses and inventory levels, enabling warehouse managers to make informed decisions regarding staffing and inventory management.

According to a study by McKinsey & Company, integrating advanced software with automated systems can increase warehouse productivity by up to 50%.

Implementing Pick-to-Box: Steps to Follow for a Successful Integration

Integrating Pick-to-Box into your warehouse management system requires careful planning and execution to ensure success. Key steps include:

- Define Goals and Expectations: Clearly outline what you aim to achieve with the implementation.

- Evaluate Current Processes: Assess existing workflows to identify areas for improvement.

- Test the Technology: Implement the system in a controlled environment to identify potential issues.

- Train Staff: Ensure that employees are adequately trained to use the new system.

- Engage External Resources: Consider hiring consultants or system integrators to assist with the implementation.

Establishing a clear communication plan with all stakeholders, including warehouse staff, IT personnel, and external partners, is essential. Regular updates and feedback loops can help address any concerns promptly. Additionally, planning for ongoing maintenance and support will ensure the system operates smoothly post-implementation.

Picking Strategies in Pick-to-Box: Batch, Wave, and Zone Picking

Warehouses utilizing Pick-to-Box can employ various picking strategies to optimize efficiency:

- Batch Picking: Involves picking multiple orders simultaneously, increasing efficiency by reducing travel time.

- Wave Picking: Groups similar orders together and processes them in batches, improving order accuracy.

- Zone Picking: Divides the warehouse into specific zones, assigning each picker to a particular area based on their expertise.

Each strategy has its own set of advantages and challenges. For instance, while batch picking can boost efficiency, it may lead to longer processing times for individual orders. Wave picking enhances accuracy but requires meticulous planning and coordination. Zone picking increases productivity and reduces congestion but may necessitate additional training and supervision for pickers. The optimal picking strategy depends on factors such as order volume, product variety, and labor availability.

Advantages of Using Pick-to-Box for E-commerce and Retail Businesses

E-commerce and retail businesses stand to gain significantly from implementing Pick-to-Box due to its ability to enhance efficiency and reduce operational costs. By automating the picking and packing tasks, businesses can allocate labor resources to other critical areas such as customer service or product development.

Pick-to-Box also minimizes the risk of errors, ensuring order accuracy and thereby improving customer satisfaction. This reduction in errors can lead to fewer returns or refunds due to incorrect orders, enhancing overall profitability.

Moreover, the system's capacity to reduce space requirements and expedite order processing times allows businesses to scale their operations without incurring substantial additional costs. According to a Logistics Management study, companies that adopt automated systems like Pick-to-Box experience up to a 25% reduction in operational costs.

Additionally, Pick-to-Box optimizes inventory management by tracking inventory levels in real-time. This capability allows businesses to restock items as needed, avoiding stockouts and reducing excess inventory. Optimized inventory levels improve cash flow and profitability by minimizing capital tied up in unsold stock.

Challenges of Implementing Pick-to-Box in Warehouses and How to Overcome Them

While Pick-to-Box offers substantial benefits, implementing the system can present challenges. One of the primary obstacles is integrating the new technology with existing warehouse management systems and processes. This integration requires meticulous planning to prevent disruptions to ongoing operations.

Other challenges include training staff on the new system, ensuring proper maintenance of the automated components, and adapting to fluctuations in demand or order volume. Resistance to change among employees can also hinder the implementation process.

To overcome these challenges, businesses should adopt a strategic approach to implementation. This includes engaging with external resources such as consultants or system integrators who specialize in warehouse automation. Additionally, providing comprehensive training and fostering a culture of adaptability can facilitate a smoother transition. Regular maintenance schedules and scalable system designs can also help manage changes in demand effectively.

Comparing Pick-to-Box with Other Automated Warehouse Systems: Which One is Right for You?

Pick-to-Box is one of several automated warehouse systems available today. Selecting the right system for your business involves evaluating your specific requirements and goals. Other popular automated systems include:

- Goods-to-Person (GTP) Systems: These systems bring products directly to workers, reducing the need for manual retrieval.

- Robotic Picking Systems: Utilize advanced robotics to enhance picking speed and accuracy.

- Shuttle Systems: Employ automated shuttles to transport goods within the warehouse efficiently.

Each system has its own set of advantages and limitations. For example, while GTP systems can significantly reduce labor costs, they may require a higher initial investment. Robotic picking systems offer high precision but might be better suited for warehouses with a large volume of similar items. Shuttle systems provide flexibility and scalability but may be complex to integrate into existing infrastructures.

The best choice depends on factors such as your product mix, order volume, available space, and budget. Conducting a thorough needs assessment and consulting with industry experts can help determine the most suitable automated system for your business.

Conclusion

Pick-to-Box is a powerful automated warehouse system that can greatly enhance efficiency and reduce order processing times for e-commerce and retail businesses. By leveraging advanced technology to automate picking and packing tasks, Pick-to-Box frees up labor resources, minimizes errors, and optimizes space usage. However, successful implementation requires careful planning, integration with existing systems, and comprehensive staff training. By following the steps outlined in this article and seeking external expertise when necessary, businesses can effectively integrate Pick-to-Box into their warehouse operations, leading to streamlined processes and improved operational performance.