Understanding Package Dimensions

When shipping or mailing packages, knowing the size and weight is crucial. One measurement that is often overlooked but equally important is the package’s girth. Girth refers to the distance around the thickest part of a package, and it can significantly affect shipping and mailing costs.

This guide explores what package girth is, why it matters, how to measure it accurately, and best practices for packaging items with optimal girth.

What is Package Girth?

Defining Package Girth

Package girth is the measurement around the largest circumference of a package. It is typically calculated by measuring the distance around the height and width of a package. Understanding girth is essential for calculating the dimensional weight, which many carriers use to determine shipping costs.

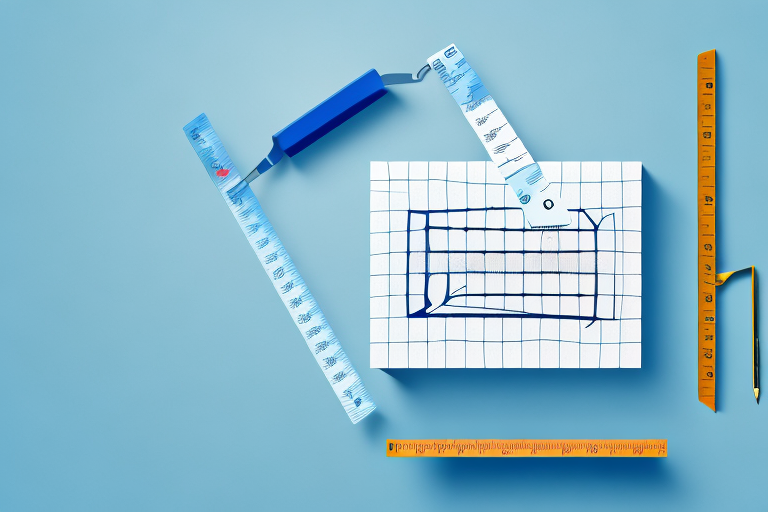

Anatomy of a Package

A package consists of three dimensions: length, width, and height. The length is the longest side, while the width and height are the shorter sides. Together, these dimensions determine the package’s overall size or volume, which is used by carriers to calculate shipping costs based on dimensional weight.

Importance of Girth in Shipping

Influence on Shipping Costs

While the actual weight of a package is a major factor in shipping costs, girth plays a significant role as well. Carriers use a formula that considers both weight and dimensions to calculate costs. For example, FedEx and UPS utilize dimensional weight pricing, which can result in higher costs for packages with greater girth.

Dimensional vs. Actual Weight

Dimensional weight is calculated by multiplying the package’s volume (length × width × height) by a dimensional factor provided by the carrier. If the dimensional weight exceeds the actual weight, the higher value is used for shipping cost calculations. This emphasizes the importance of keeping package girth minimal to avoid unnecessary fees.

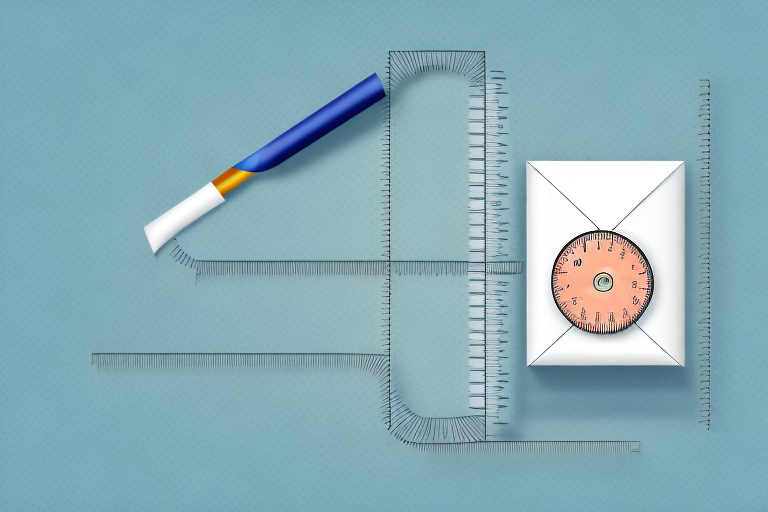

Measuring Package Girth

Accurate Measurement Techniques

The most accurate way to measure package girth is by using a flexible tape measure. Place one end at the bottom of the package’s thickest part, wrap it around the width and height, and record the measurement where the tape meets the starting point.

Alternative Methods

If a tape measure is unavailable, alternative methods include using a string or ribbon. Wrap the string around the package, mark the point where it overlaps, and then measure the length with a ruler. However, these methods may be less accurate and can lead to errors in girth calculation.

Girth Limitations by Carrier

USPS Girth Limits

The United States Postal Service (USPS) has a girth limitation of 108 inches for package mailing. Packages exceeding this limit may incur additional fees or be rejected for standard shipping services.

UPS and FedEx Girth Limits

UPS and FedEx have higher girth limits, typically up to 130 inches. Exceeding these limits may require special handling and incur extra costs.

Strategies to Reduce Package Girth

Optimal Packaging Practices

Using appropriately sized packaging is key to minimizing girth. Choose boxes that fit the product snugly to reduce excess space. Insufficient space can lead to increased girth and higher shipping costs.

Utilizing Vacuum-Sealed Bags

For items like clothing and textiles, vacuum-sealed bags can significantly reduce package girth by compressing the contents. This not only lowers shipping costs but also minimizes the environmental impact.

Choosing the Right Shipping Supplies

Select flat-rate boxes or custom-sized packaging offered by carriers. These options can optimize girth while providing the necessary protection for the item being shipped.

Common Mistakes in Measuring Girth

Incorrect Measurement Points

A common error is measuring the thinnest part of the package instead of the thickest. Accurate girth measurement requires identifying and measuring around the package's largest circumference.

Not Accounting for Packaging Materials

Failing to include the thickness of packaging materials can lead to underestimating girth. Ensure that all packing materials are considered in the measurement to avoid unexpected shipping costs.

Understanding Dimensional Weight

How Dimensional Weight Affects Shipping Costs

Dimensional weight takes into account the space a package occupies during transit. Carriers calculate it by applying a dimensional factor to the package’s volume. A higher girth increases the volume, leading to a higher dimensional weight and thus higher shipping costs.

Carriers' Dimensional Weight Policies

Different carriers have varying dimensional weight policies. For instance, as of 2023, FedEx calculates dimensional weight using a factor of 139 (in inches), while UPS uses a factor of 139 for domestic and 166 for international shipments. Understanding these policies helps optimize packaging to reduce costs.

The Future of Packaging and Girth Considerations

Sustainable Packaging Trends

There is a growing shift towards sustainable packaging solutions that reduce girth and environmental impact. Utilizing recyclable materials and minimizing packaging sizes are becoming industry standards.

Technological Advances

Advancements in packaging technology, such as modular packaging systems and smart packaging, allow for more efficient space utilization, thereby reducing girth and optimizing shipping costs.

Real-Life Examples of Girth Impact

Case Studies in Shipping Efficiency

Companies that have optimized their packaging girth have reported significant cost savings and reduced environmental footprints. For example, Amazon has implemented advanced packaging algorithms to minimize girth, resulting in lower shipping costs and enhanced delivery efficiency.

Impact on Small Businesses

Small businesses paying close attention to package girth can remain competitive by reducing shipping expenses. Efficient packaging strategies enable them to offer better pricing and faster shipping to customers.

In conclusion, understanding and managing package girth is crucial for efficient and cost-effective shipping. By accurately measuring girth, adhering to carrier limitations, and employing strategies to minimize girth, both businesses and individuals can optimize their shipping practices.