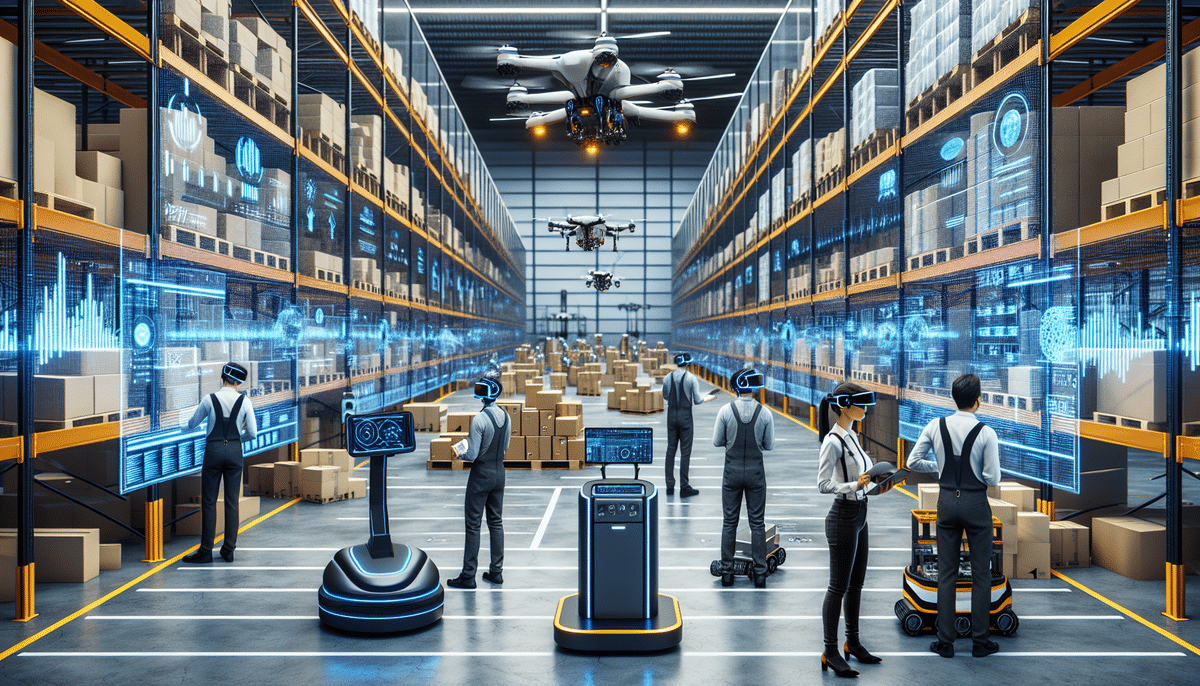

Introduction to Warehouse Automation

In recent years, technology has revolutionized the way businesses operate, and warehouses are no exception. According to a Gartner's report on warehouse automation, the global warehouse automation market is expected to reach USD 30 billion by 2026. Warehousing processes have evolved significantly, transitioning from manual to automated systems. With the rise of warehouse automation software, businesses can optimize their operations and streamline distribution channels more effectively than ever before. This article explores the benefits of warehouse automation software and the pivotal role of technology in modern warehousing.

Evolution and Technological Advancements in Warehousing

Warehousing has undergone significant transformations from its early manual processes to the adoption of advanced automated systems. Historically, warehouses relied on manual labor for tasks such as picking items from shelves, packing orders, and handling shipments. This method was not only time-consuming but also prone to human error. A study by Supply Chain Digital highlights that manual warehousing limited businesses in terms of inventory capacity and increased error rates during order fulfillment.

Modern Warehouse Management Systems (WMS) leverage automation to address these challenges. Automation enhances accuracy, speed, and safety within warehouse operations. By integrating automated systems, businesses can improve operational efficiency, reduce errors, enhance workflow, and significantly lower labor costs.

One of the most significant advantages of warehouse automation is the ability to manage larger inventory volumes. Automated systems handle a higher number of orders, allowing businesses to scale their inventory without the constraints of manual processes. Furthermore, automation minimizes errors in picking and packing, leading to fewer returns and higher customer satisfaction. Overall, automated systems enable businesses to streamline operations, reduce costs, and boost efficiency.

Core Functionalities and Benefits of Automation Software

Inventory Management

Effective inventory management is crucial for businesses dealing with physical goods. An accurate tracking system optimizes warehouse storage and order fulfillment while reducing inventory errors. Warehouse automation software enhances inventory management by automating the tracking process. When a new item arrives, it is scanned, logged into the system, and assigned a specific location on the warehouse shelves. The software then monitors the item's movement, providing precise tracking information.

Picking and Packing

Picking and packing are critical processes in warehousing that are susceptible to errors when done manually. Automated picking and packing systems utilize technology to select, pack, and label items, reducing the reliance on manual labor. This automation results in increased accuracy, higher productivity, and fewer errors. According to Forbes, businesses that implement automated systems experience a significant reduction in order errors and an improvement in customer satisfaction.

Moreover, automation accelerates the picking and packing processes. Automated systems clear items from shelves more swiftly, leading to quicker order fulfillment and shipping. This increased speed enhances customer satisfaction through faster delivery times.

Sorting and Routing

Warehouse automation software is instrumental in automating the sorting and routing of items within the warehouse. Automated routing systems ensure that products are directed to their designated locations once they have been picked and packed.

The software enhances operational efficiency by enabling businesses to route products to customers swiftly and accurately. It also ensures that returns are handled correctly, with items being picked from shelves and returned to their proper locations without delays.

Shipping and Receiving

Manual shipping and receiving processes are time-consuming and prone to errors. Automation streamlines these processes, ensuring accurate order processing and shipment. Warehouse automation software ensures that each shipment is correctly labeled with the appropriate details, reducing order errors and enhancing customer satisfaction.

Automation also helps businesses cut costs by minimizing labor expenses associated with manual shipping and receiving tasks. With automated systems, businesses can process more orders in less time, allowing for more efficient resource allocation. This increase in productivity contributes to higher profitability.

Impact on Labor Costs and Workplace Safety

One of the most significant advantages of warehouse automation software is the substantial reduction in labor costs. Automated systems can perform tasks that would otherwise require multiple employees, leading to lower labor expenses. Additionally, automation enhances workplace safety by reducing the risk of injuries. Automated machinery can handle heavy loads and perform hazardous tasks, minimizing the chances of worker accidents.

Automation also boosts operational efficiency and accuracy. Automated systems operate continuously without the need for breaks, resulting in faster and more consistent output. This consistency leads to improved customer satisfaction and increased company profits.

Moreover, warehouse automation contributes to environmental sustainability. Automated systems optimize energy usage and reduce waste, making warehouses more eco-friendly. This sustainability is increasingly important for companies aiming to improve their corporate social responsibility and attract environmentally conscious customers.

Future Trends and Innovations

Technology in warehouse automation is rapidly advancing, with future trends pointing towards even more sophisticated systems. Augmented Reality (AR) and Virtual Reality (VR) are set to play significant roles, enabling workers to perform tasks with enhanced precision and training capabilities. These technologies can improve accuracy in order picking and increase overall operational efficiency.

The use of drones and automated delivery vehicles is another emerging trend. These technologies promise to enhance delivery speeds, paving the way for same-day and even same-hour deliveries. According to a report by Forbes, the integration of drones in warehouses can reduce order picking times by up to 50%, significantly improving delivery times to customers.

Choosing the Right Warehouse Automation Software

Selecting the appropriate warehouse automation software is a critical decision for any business. It's essential to assess your specific needs, considering factors such as the size of your operation, budget constraints, and existing warehouse processes. The chosen software should not only address your current requirements but also offer scalability to accommodate future growth.

Key features to look for include real-time inventory tracking, integration capabilities with other business systems, user-friendly interfaces, and robust support services. Additionally, evaluating the software’s compatibility with existing hardware and its ability to adapt to evolving technological advancements is crucial for long-term success.

Success Stories in Warehouse Automation Implementation

Real-world examples illustrate the effectiveness of warehouse automation. Amazon is a prime example of a company that has successfully integrated warehouse automation software to manage its vast inventory. By automating processes from receiving items to packaging them for delivery, Amazon has significantly reduced order fulfillment times and boosted productivity. According to Amazon’s annual report, automation has been a key factor in their ability to handle millions of orders efficiently each day.

Another success story is DHL, which implemented advanced warehouse automation software to streamline operations for its global logistics network. The result was a 30% increase in order processing speed and a 25% reduction in labor costs, demonstrating the tangible benefits of automation in warehousing.

Common Misconceptions and Challenges

Debunking Misconceptions

There are several misconceptions surrounding warehouse automation software, particularly regarding its cost and complexity. Many business owners assume that automation is prohibitively expensive and overly complex to implement, especially for small and medium-sized enterprises. However, the cost of automation has been steadily decreasing, and modern systems are designed to be user-friendly and easily integrated into existing operations.

In reality, the return on investment (ROI) from warehouse automation can be substantial, with businesses experiencing cost savings, increased efficiency, and improved accuracy. Additionally, many vendors offer scalable solutions that can be customized to fit the specific needs and budgets of different businesses, making automation accessible to a wider range of companies.

Overcoming Implementation Challenges

Implementing warehouse automation software comes with its set of challenges, including the learning curve, system integration, and data migration. However, these challenges can be effectively managed with proper planning and execution.

First, providing comprehensive training to employees ensures that they are comfortable with the new systems and can utilize them effectively. Second, choosing software that offers seamless integration with existing systems minimizes disruptions and enhances overall workflow. Lastly, careful data migration strategies, including data validation and testing, ensure that accurate information is transferred without loss or corruption.

Collaborating with experienced vendors and seeking expert advice can also facilitate a smoother transition to automated systems. By addressing these challenges proactively, businesses can successfully implement warehouse automation software and reap its benefits.

Conclusion: The Future of Warehousing with Automation Technology

In conclusion, warehouse automation software represents the future of warehousing. The software offers numerous benefits that are indispensable for modern businesses, including increased productivity, enhanced accuracy, and improved safety. As technology continues to advance, we can anticipate even greater innovations that will further transform warehouse operations. Embracing automation is not merely an option but a necessity for businesses aiming to stay competitive in the ever-evolving landscape of warehousing and logistics.