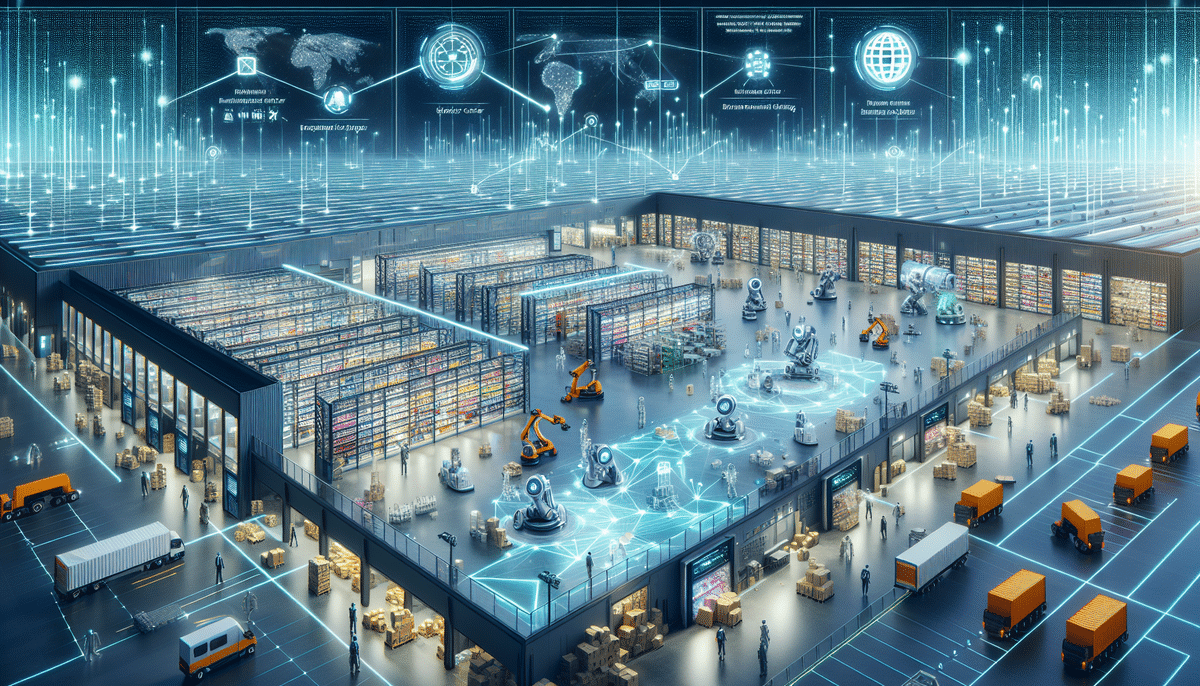

What Is Warehousing? An Overview of the Logistics Process

Welcome to our comprehensive guide on warehousing and the logistics process. In this article, we'll delve into various aspects of warehousing—from its history and role in the supply chain to the types of warehouses, design and layout considerations, benefits, challenges, and emerging trends. As of 2023, the global warehousing market is valued at over $1 trillion, highlighting its critical importance in the supply chain (IBISWorld). By the end of this article, you'll gain a thorough understanding of how warehousing operates, its significance in modern business, and the future of logistics in the digital age.

The Role of Warehousing in the Supply Chain

Warehousing is a pivotal component of the supply chain, serving as an intermediary between manufacturers and customers. Its primary role is to store and protect goods until they are ready for distribution to their final destinations. Effective warehousing ensures sufficient stock levels to meet customer demand, thereby preventing delays in the production and distribution processes. Additionally, warehousing facilitates transportation logistics and helps maintain the quality of goods.

Beyond storage, warehousing enhances the overall efficiency of the supply chain. Strategically located warehouses can significantly reduce transportation costs and improve delivery times. By consolidating shipments from multiple suppliers, warehouses help minimize the number of deliveries, thereby streamlining supply chain operations.

Inventory management is another critical function of warehousing. By accurately tracking inventory levels and monitoring demand, warehouses enable companies to optimize their stock, reducing the risk of stockouts and excess inventory. This optimization can lead to substantial cost savings and higher customer satisfaction, as orders are fulfilled promptly and accurately (Supply Chain Digital).

Types of Warehouses: Understanding the Differences

Warehouses come in various types, each designed to serve specific functions, sizes, and storage capacities. The most common types include:

- Public Warehouses: Owned and operated by third-party logistics providers, offering services such as storage, inventory management, and transportation.

- Private Warehouses: Owned by individual companies for their exclusive use, tailored to meet specific storage and management needs.

- Distribution Centers: Primarily focused on the efficient distribution of goods, often located near major transportation hubs to facilitate quick delivery.

- Fulfillment Centers: Specialized warehouses designed to handle order fulfillment, commonly used by e-commerce businesses to manage and ship online orders.

- Climate-Controlled Warehouses: Designed to store goods that require specific temperature and humidity conditions, such as perishable food items, pharmaceuticals, and chemicals.

Climate-controlled warehouses are equipped with advanced systems like refrigeration units, dehumidifiers, and air conditioning to maintain the necessary environmental conditions. These facilities also utilize sophisticated monitoring systems to ensure continuous compliance with required standards (ScienceDirect).

The History of Warehousing: From Ancient Times to Modern Day

The concept of warehousing has ancient roots, with merchants in civilizations like Egypt and Mesopotamia storing goods in secure locations such as temples and palaces. Over centuries, warehousing evolved significantly, especially during the Industrial Revolution, which saw the rise of mass production and the need for large-scale storage facilities. Today, warehousing is a cornerstone of the global economy, representing a multi-billion-dollar industry (Encyclopaedia Britannica).

In recent years, the boom in e-commerce has driven substantial growth in the warehousing sector. Online retailers require extensive warehousing capabilities to manage large inventories and ensure swift order fulfillment. This surge has spurred the adoption of new technologies and strategies, including automation and robotics, to enhance warehouse efficiency and meet the demands of the digital marketplace (McKinsey & Company).

Key Components of a Warehouse: Design and Layout

Effective warehouse operations hinge on meticulous planning and design. Key components include:

- Layout: A well-designed layout maximizes space utilization, streamlines operations, and ensures easy access to goods. This includes designated areas for receiving, storage, picking, packing, and shipping.

- Racking Systems: Efficient racking systems, such as pallet racks, shelving, and automated storage and retrieval systems (AS/RS), optimize storage capacity and facilitate easy access to products.

- Material Handling Equipment: Essential for moving goods within the warehouse, equipment like forklifts, conveyors, and automated guided vehicles (AGVs) enhance operational efficiency and reduce manual labor.

- Security Systems: Protecting valuable goods is paramount. Security measures include surveillance cameras, access control systems, and alarm systems to prevent theft and damage.

In addition to physical components, effective warehouse management involves robust inventory management, order processing, and shipping and receiving procedures. A skilled workforce, supported by regular training and performance evaluations, ensures smooth operations and high levels of productivity (Investopedia).

Benefits of Warehousing: Why It's Essential for Businesses

Warehousing offers numerous benefits that are crucial for business success:

- Inventory Management: Efficient warehousing helps maintain optimal inventory levels, reducing the risk of stockouts and overstock situations.

- Buffer Between Production and Sales: Warehousing acts as a buffer, ensuring a steady flow of goods from production to sales without interruptions.

- Logistics Customization: Businesses can tailor their logistics strategies to meet unique needs, enhancing flexibility and responsiveness.

- Value-Added Services: Services such as kitting, assembly, and labeling improve the customer experience by providing customized and streamlined order fulfillment.

- Cost Reduction: By consolidating shipments and optimizing transportation routes, warehousing helps businesses lower transportation costs.

- Flexibility to Respond to Demand Changes: Warehousing provides the flexibility to adapt to fluctuations in demand, essential for managing seasonal products or unexpected market shifts.

Overall, warehousing is a vital aspect of any successful business strategy, contributing to improved efficiency, reduced costs, and enhanced customer satisfaction (Harvard Business Review).

How Warehouses Operate: A Behind-the-Scenes Look

Warehouse operations are structured around a series of standard procedures that ensure the efficient handling of goods. The typical workflow includes:

- Receiving: Goods are received, inspected for damage, and recorded into the inventory system.

- Storing: Items are stored in designated areas within the warehouse, organized for easy retrieval.

- Picking: Orders are selected from inventory based on customer demand, using methods like batch picking or zone picking.

- Packing: Selected items are packaged securely for shipment, often involving labeling and documentation.

- Shipping: Packed orders are dispatched to their final destinations, with tracking information provided to customers.

Technology plays a crucial role in modern warehouse operations. Automated inventory management systems, barcode scanning, and RFID technology enhance accuracy and efficiency, minimizing errors and speeding up processes. Advanced warehouse management software (WMS) integrates these technologies to provide real-time visibility into inventory levels, order statuses, and operational performance (Software Advice).

Safety is another critical aspect of warehouse operations. Proper training, safety protocols, and the use of personal protective equipment (PPE) are essential to prevent accidents and ensure a safe working environment for all employees (OSHA).

Inventory Management in Warehousing: Best Practices and Tools

Effective inventory management is essential for optimizing warehouse operations. Best practices include:

- Cycle Counting: Regularly counting a subset of inventory to ensure accuracy without disrupting operations.

- Demand Forecasting: Predicting future inventory needs based on historical data and market trends to maintain optimal stock levels.

- Automated Order Replenishment: Using automated systems to reorder stock when inventory levels fall below predefined thresholds.

Advanced tools and technologies enhance inventory management efficiency:

- Warehouse Management Software (WMS): Comprehensive software solutions that manage inventory, orders, and warehouse operations.

- Barcoding and RFID: Technologies that facilitate accurate tracking and identification of inventory items.

- Inventory Optimization Tools: Software that analyzes data to recommend optimal inventory levels and reorder points.

Proper storage and organization are also vital. Implementing effective shelving and labeling systems, along with a first-in, first-out (FIFO) approach, ensures that older products are used or sold before newer ones, reducing the risk of obsolescence and waste. Regular audits and reviews of inventory levels help identify discrepancies and areas for improvement, ensuring the inventory system remains accurate and efficient (Supply Chain Dive).

Challenges Faced by Warehouses Today: Solutions and Strategies

Warehousing today faces several challenges, including:

- Labor Shortages: The scarcity of skilled labor can hinder warehouse operations and productivity.

- Fluctuating Demand: Variations in demand, especially seasonal spikes, complicate inventory management and resource allocation.

- Supply Chain Disruptions: Events like natural disasters, geopolitical tensions, and pandemics can disrupt supply chains, leading to delays and increased costs.

- Sustainability Demands: Increasing pressure to adopt eco-friendly practices necessitates changes in warehouse operations.

To address these challenges, warehouses are implementing various solutions and strategies:

- Automation: Utilizing automated systems and robotics to enhance productivity and reduce reliance on manual labor.

- Cross-Training Staff: Training employees in multiple roles to increase flexibility and mitigate the impact of labor shortages.

- Contingency Planning: Developing backup plans to respond to unforeseen disruptions, ensuring continuity of operations.

- Sustainable Practices: Adopting renewable energy sources, reducing waste, and optimizing transportation routes to minimize environmental impact.

Emphasizing sustainability not only meets consumer expectations but also contributes to long-term cost savings and corporate responsibility (GreenBiz).

Trends in Warehousing: Technology Advancements and Future Outlook

The warehousing industry is rapidly evolving, driven by technological advancements and changing market dynamics. Key trends include:

- Automation and Robotics: The integration of robotics for picking, packing, and material handling is increasing efficiency and reducing operational costs (Robotics Business Review).

- Artificial Intelligence (AI) and Machine Learning: AI-powered systems are enhancing demand forecasting, inventory optimization, and predictive maintenance.

- Internet of Things (IoT): IoT devices provide real-time data on inventory levels, equipment status, and environmental conditions, enabling better decision-making.

- Blockchain Technology: Enhances transparency and traceability in the supply chain, ensuring data integrity and reducing fraud (Forbes).

- Drones and Autonomous Vehicles: Used for inventory management, surveillance, and transportation within the warehouse, improving speed and accuracy.

- Cloud-Based Warehouse Management Systems: Offering greater flexibility, scalability, and accessibility for managing warehouse operations.

- Sustainability Initiatives: Focused on reducing carbon footprints through energy-efficient practices and eco-friendly materials.

The future of warehousing lies in leveraging these technologies to create more efficient, responsive, and sustainable operations. As global trade continues to expand and e-commerce grows, the demand for advanced warehousing solutions will only increase, driving further innovation in the industry (Forbes Technology Council).

The Role of Data Analytics in Warehouse Optimization

Data analytics has become an indispensable tool for optimizing warehouse operations. By leveraging data, warehouse managers can:

- Identify Trends: Analyze historical data to uncover patterns in inventory movement, seasonal demand, and operational performance.

- Forecast Demand: Use predictive analytics to anticipate future inventory needs, enabling proactive inventory management.

- Optimize Operations: Streamline processes by identifying bottlenecks, inefficiencies, and areas for improvement based on real-time data insights.

- Reduce Costs: Highlight cost-saving opportunities through data-driven decision-making, such as optimizing inventory levels and improving resource allocation.

Advanced analytics tools, including machine learning algorithms and business intelligence platforms, empower warehouses to make informed decisions, enhance operational efficiency, and maintain a competitive edge in the market (SAS Insights).

Sustainability in Warehousing: Eco-Friendly Practices for a Greener Future

Adopting sustainable practices in warehousing is becoming increasingly important as businesses strive to reduce their environmental impact. Key eco-friendly practices include:

- Energy Efficiency: Implementing energy-efficient lighting, HVAC systems, and machinery to reduce energy consumption.

- Renewable Energy Sources: Utilizing solar panels, wind energy, and other renewable sources to power warehouse operations.

- Waste Reduction: Minimizing waste through recycling programs, reducing packaging materials, and optimizing inventory to prevent overstocking.

- Green Building Design: Constructing warehouses with sustainable materials and designs that enhance energy efficiency and environmental responsibility.

- Alternative Transportation Methods: Using electric vehicles or bicycles for last-mile deliveries to lower carbon emissions.

- Water Conservation: Implementing water-saving technologies and practices to reduce water usage.

By integrating these sustainable practices, warehouses can contribute to environmental conservation, comply with regulatory requirements, and meet the growing consumer demand for eco-friendly products and services (GreenBiz).

Case Studies: Successful Warehousing Strategies from Leading Companies

Leading companies are setting benchmarks in warehousing by implementing innovative strategies to enhance efficiency and customer satisfaction:

- Amazon: Amazon utilizes robotic picking systems in their fulfillment centers, which has significantly increased productivity and reduced fulfillment times. Their use of automated guided vehicles (AGVs) and sophisticated warehouse management systems enables seamless operations at a massive scale (Forbes).

- Walmart: Walmart has integrated autonomous trucks for last-mile deliveries, reducing transportation costs and improving delivery times. Their investment in technology and automation has optimized their supply chain, ensuring timely delivery of products to customers (The Wall Street Journal).

- Zara: Zara employs a responsive supply chain strategy with strategically located warehouses that allow for rapid replenishment of stock, enabling the company to quickly adapt to changing fashion trends and consumer demands (Bain & Company).

- Alibaba: Alibaba has implemented smart warehousing solutions, including AI-driven inventory management and automated sorting systems, to handle the vast volume of orders generated by their e-commerce platform efficiently (Harvard Business Review).

These case studies demonstrate how innovative strategies and technology adoption can lead to significant improvements in warehouse operations, driving business success and customer satisfaction.

The Future of Warehousing and Logistics in the Digital Age

The future of warehousing and logistics is poised for transformation, driven by digital technologies and evolving market demands. Key trends shaping the future include:

- Integration of IoT, AI, and Blockchain: These technologies will enable real-time tracking of goods, enhance predictive maintenance, and ensure data integrity across the supply chain.

- Advanced Automation: Increased use of robotics and automated systems will further streamline warehouse operations, enhancing speed and accuracy.

- Enhanced Data Analytics: Continued advancements in data analytics will provide deeper insights into warehouse performance, enabling more strategic decision-making.

- Sustainability Focus: Growing emphasis on eco-friendly practices will drive the adoption of green technologies and sustainable operations in warehouses.

- Omnichannel Fulfillment: Warehouses will increasingly support omnichannel retail strategies, requiring flexible and efficient fulfillment processes to handle diverse order types.

- Smart Warehousing: The implementation of smart technologies, such as augmented reality (AR) and virtual reality (VR), will enhance training, maintenance, and operational efficiency.

The convergence of these technologies and trends will create more efficient, responsive, and sustainable warehousing operations. As global trade continues to expand and consumer expectations evolve, the warehousing sector must embrace innovation to stay competitive and meet the demands of the digital age (McKinsey & Company).

In conclusion, warehousing is a fundamental aspect of the logistics process, providing essential storage, protection, and distribution of goods. Successful warehousing operations require meticulous planning, efficient design, and the integration of advanced technologies. Looking ahead, the future of warehousing lies in leveraging digital innovations to enhance efficiency, productivity, and sustainability. By adopting these progressive practices, businesses can maintain a competitive edge in the ever-evolving landscape of logistics.

```