What You Need to Know About Palletized Shipping

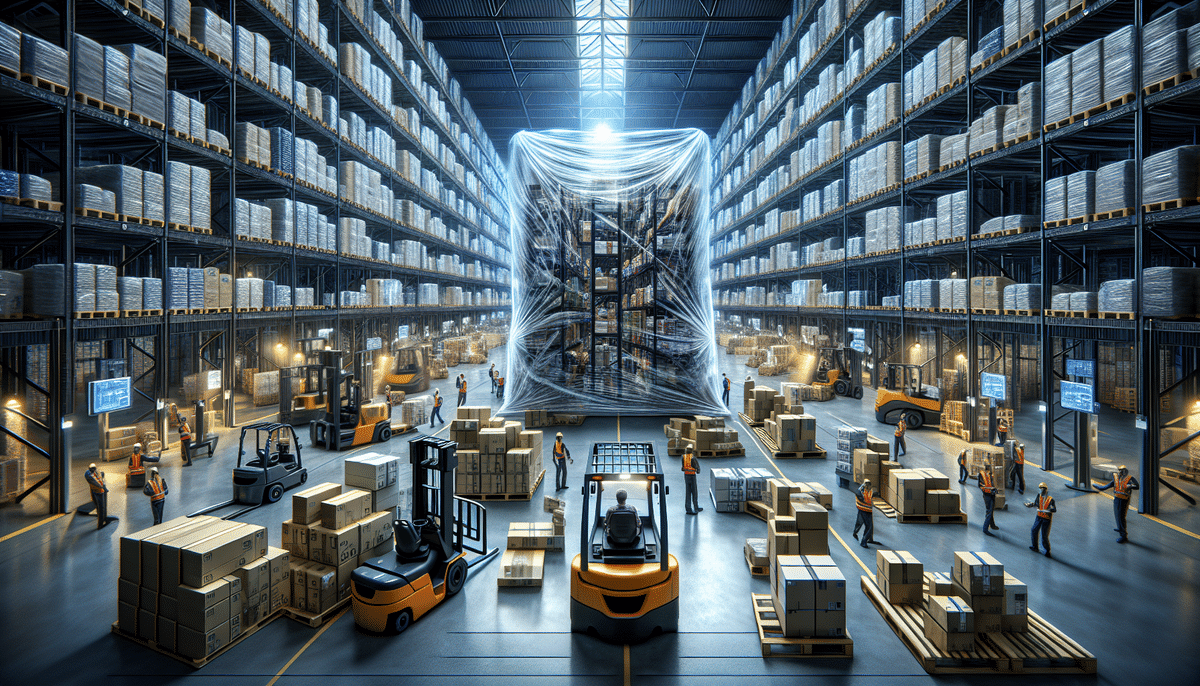

Palletized shipping is a widely utilized transportation method that enables businesses to move large quantities of goods efficiently from one location to another. This method involves stacking boxes or items onto a pallet, securing them with wrapping, and transporting them to their designated destination. Palletized shipping offers numerous advantages, including improved efficiency, reduced shipping costs, and enhanced safety for the transported goods. In this article, we will delve into the fundamentals of palletized shipping and provide comprehensive insights into this transportation method.

The Basics of Palletized Shipping: An Overview

Palletized shipping utilizes pallets as the primary means of transporting goods. A pallet is a flat structure typically made from wood, plastic, or metal, designed to support items stacked on top. Once items are securely stacked, they are wrapped using plastic or shrink wrap to ensure stability during transit.

The adoption of pallets in shipping offers several benefits:

- Efficiency: Pallets allow businesses to move large quantities of goods without the risk of individual boxes or items being damaged.

- Cost Reduction: Standardized pallet sizes optimize space utilization, reducing the number of trips required and lowering shipping costs.

- Safety: Securely stacked and wrapped goods are less likely to shift or fall, ensuring safer transportation.

- Environmental Impact: Utilizing pallets can minimize packaging materials and reduce shipping waste.

According to the National Motor Freight Classification (NMFC), palletized shipping is integral to supply chain logistics, offering a standardized approach to freight movement.

Advantages of Palletized Shipping for Your Business

One of the most significant advantages of palletized shipping is the reduction in shipping costs. By consolidating shipments onto pallets, businesses can minimize the number of individual boxes or items shipped, leading to substantial savings, especially for companies that frequently transport large volumes of goods.

Palletized shipping also enhances the safety of transported items. Secure stacking reduces the risk of damage during transit, while the use of wrapping materials like plastic or shrink wrap ensures items remain in place, protecting them from shifting or falling.

Additionally, palletized shipping streamlines the loading and unloading process. Businesses can save time and increase productivity by reducing the effort required to handle individual boxes, allowing them to focus on other critical operations.

Furthermore, palletized shipping simplifies tracking and inventory management. Pallets can be easily tracked throughout the supply chain, enabling businesses to monitor shipment movement and maintain accurate inventory levels. This efficiency is supported by technologies such as Radio-Frequency Identification (RFID), which enhances real-time tracking capabilities.

How to Properly Prepare Goods for Palletized Shipping

Proper preparation of goods is essential for safe and efficient palletized shipping. Follow these steps to ensure your goods are adequately prepared:

- Packaging and Labeling: Ensure all items are properly packaged to prevent damage. Clearly label each package with relevant information, including destination, handling instructions, and product details.

- Weight Distribution: Distribute the weight of items evenly across the pallet to prevent tipping or collapsing. Place heavier items at the bottom and lighter items on top.

- Stacking: Stack items uniformly to maintain balance. Avoid overhanging or uneven stacking, which can compromise the pallet's stability.

- Wrapping: Use high-quality plastic or shrink wrap to secure the items to the pallet tightly. This prevents movement during transportation, reducing the risk of damage.

- Pallet Selection: Choose the appropriate pallet type and size based on the weight and dimensions of your goods. Inspect pallets for any damage or defects before use to ensure they are safe for transport.

For more detailed guidelines, refer to the American National Standards Institute (ANSI) standards on palletized shipping.

Common Types of Pallets Used in Shipping and Their Differences

Several types of pallets are used in shipping, each with distinct advantages and disadvantages:

- Wood Pallets: The most commonly used due to their affordability and versatility. They are suitable for a wide range of applications but may be susceptible to damage and less hygienic compared to other types.

- Plastic Pallets: Lightweight and durable, making them ideal for shipping delicate items. They are resistant to moisture and pests but are generally more expensive than wood pallets.

- Metal Pallets: Highly durable and capable of withstanding heavy loads. They are hygienic and suitable for industries requiring stringent sanitary conditions, such as pharmaceuticals and food processing. However, they are the most expensive option.

- Hybrid Pallets: Combine materials like wood and plastic or metal and plastic to leverage the benefits of each. For example, a wood-plastic hybrid pallet offers the durability of plastic with the affordability of wood.

Choosing the right pallet depends on factors such as the type of goods being shipped, transportation mode, and budget constraints. For instance, businesses shipping food products should use food-grade pallets to comply with health and safety regulations.

For more information on pallet types, consult the International Pallet Association (IPA).

The Importance of Proper Stacking and Wrapping Techniques for Palletized Shipping

Proper stacking and wrapping are critical for the success of palletized shipping. Incorrect stacking or inadequate wrapping can lead to damage during transportation and pose safety hazards.

Stacking Techniques:

- Even Weight Distribution: Distribute the weight of items evenly across the pallet to prevent tipping.

- Consistent Layering: Stack items in a uniform pattern to maintain balance and stability.

- Surface Stability: Ensure the bottom layer is on a flat, stable surface to support the entire stack.

Wrapping Techniques:

- Use Appropriate Materials: Utilize stretch film or shrink wrap to secure items tightly to the pallet.

- Multiple Layers: Apply multiple layers of wrapping to reinforce stability and prevent movement.

- Edge Protection: Ensure all edges and corners are well-wrapped to protect goods from shifting.

Consider the nature of the goods being shipped; fragile items may require additional padding or cushioning to prevent damage. Environmental factors such as temperature and humidity should also be considered, as they may necessitate specialized packaging or handling.

Adhering to guidelines from organizations like the American National Standards Institute (ANSI) can help ensure proper stacking and wrapping practices.

Tips for Maximizing Space and Efficiency in Palletized Shipping

Maximizing space and efficiency in palletized shipping can lead to significant cost savings and smoother operations. Here are some strategies to achieve this:

- Choose the Right Pallet Size: Select pallet sizes that optimize space utilization within your shipping containers or trucks.

- Efficient Stacking: Arrange items to maximize the use of vertical space without compromising stability.

- Consolidate Shipments: Combine multiple shipments into a single pallet to reduce the number of trips and associated costs.

- Use Collapsible Pallets or Containers: These can be folded or stacked when not in use, saving storage space.

- Implement Automated Systems: Utilize automated sorting and stacking systems to enhance efficiency and reduce manual labor.

By adopting these practices, businesses can enhance their shipping efficiency, reduce costs, and improve overall logistics performance.

Understanding Freight Classifications and Weight Limits for Palletized Shipping

Freight classifications and weight limits are essential factors in palletized shipping that influence shipping rates and compliance with carrier regulations. The National Motor Freight Traffic Association (NMFTA) has developed a classification system to categorize different types of freight, which carriers use to determine shipping rates.

Freight Classification: This system is based on several criteria, including the weight, dimensions, density, handling, and liability of the goods being shipped. Accurate classification ensures appropriate pricing and handling requirements.

Weight Limits: Weight restrictions vary depending on the carrier and the type of pallet used. It's crucial to verify with your carrier regarding any specific weight limitations to avoid additional charges or shipment delays.

Packaging Considerations: Proper packaging is vital to withstand the weight and handling during transportation. Using durable pallets and secure wrapping or strapping materials ensures the safety of the goods and compliance with carrier standards.

For detailed guidelines on freight classification, refer to the NMFTA's official documentation.

Choosing the Right Carrier for Your Palletized Shipment

Selecting the appropriate carrier is crucial for ensuring the safe and timely delivery of your palletized shipments. Consider the following factors when choosing a carrier:

- Price: Compare rates from multiple carriers to find competitive pricing that fits your budget.

- Reliability: Research carrier reliability by reviewing their track record for on-time deliveries and handling of goods.

- Service Quality: Assess the quality of service, including customer support, tracking capabilities, and handling procedures.

- Specialized Services: If you have specific shipping needs, such as temperature-controlled transport or handling of hazardous materials, ensure the carrier can accommodate these requirements.

- Reputation: Choose carriers with positive reviews and testimonials from other businesses to ensure trustworthy service.

Conducting thorough research and possibly negotiating terms with carriers can lead to better shipping experiences and cost-effective solutions.

Cost Considerations for Palletized Shipping: Comparing Freight Rates and Services

Understanding the cost factors involved in palletized shipping is essential for budget planning and optimizing expenses. Key considerations include:

- Shipping Distance: Longer distances generally incur higher shipping costs due to increased fuel and labor expenses.

- Weight and Dimensions: Heavier and larger shipments may result in higher rates per kilogram or per cubic meter.

- Pallet Type: The choice of pallet (wood, plastic, metal) can affect costs, with more durable materials typically being more expensive.

- Service Level: Expedited shipping services or specialized handling may come at a premium compared to standard shipping options.

- Carrier Fees: Additional fees such as fuel surcharges, accessorial charges, and insurance should be factored into the overall cost.

When comparing freight rates, it's important to evaluate not only the price but also the services offered to ensure they align with your shipping needs. Utilizing online freight calculators and requesting quotes from multiple carriers can aid in making informed decisions.

For further information on freight rates, visit the Freightos platform.

Common Challenges and Solutions in Palletized Shipping

Palletized shipping, while efficient, can present several challenges. Understanding these issues and implementing effective solutions is key to maintaining smooth operations:

- Damage to Goods: Improper stacking or inadequate wrapping can lead to product damage. Solution: Ensure proper stacking techniques and secure wrapping to protect items during transit.

- Improper Stacking and Wrapping: Inconsistent stacking or insufficient wrapping can compromise shipment integrity. Solution: Train staff on correct stacking and wrapping procedures and regularly inspect shipments before dispatch.

- Carrier Delays: Unreliable carriers may cause delays in shipment delivery. Solution: Select reputable carriers with proven track records and establish clear communication channels to monitor shipment progress.

- Inventory Management: Difficulty in tracking palletized goods can lead to inventory discrepancies. Solution: Implement robust inventory management systems with real-time tracking capabilities.

- Regulatory Compliance: Non-compliance with shipping regulations can result in fines or shipment rejections. Solution: Stay informed about relevant regulations and ensure all shipments meet necessary compliance standards.

By proactively addressing these challenges, businesses can enhance the reliability and efficiency of their palletized shipping operations.

Best Practices for Receiving and Inspecting Palletized Shipments

Properly receiving and inspecting palletized shipments ensures that goods arrive in good condition and meet quality standards. Follow these best practices:

- Initial Inspection: Upon receiving a shipment, inspect the pallet for any visible signs of damage, such as broken boards or compromised wrapping.

- Unpacking: Carefully remove the wrapping materials to access the contents without causing additional damage.

- Item Verification: Check the received items against the shipment documentation to ensure all goods are accounted for and match the order specifications.

- Damage Assessment: Examine each item for any defects or damage incurred during transit. Document any discrepancies or damages.

- Reporting: Promptly report any issues to the carrier or supplier to initiate claims or corrective actions as needed.

- Storage: Store received goods appropriately, ensuring they are placed in suitable conditions to maintain their quality and prevent damage.

Implementing a standardized receiving and inspection process can reduce errors, prevent losses, and maintain the integrity of your inventory.

How Technology is Revolutionizing Palletized Shipping

Advancements in technology are transforming palletized shipping, enhancing efficiency, safety, and reliability. Key technological innovations include:

- GPS Tracking: Real-time tracking allows businesses to monitor the location and status of their shipments, providing greater transparency and control over the supply chain.

- Automated Sorting Systems: These systems streamline the handling and distribution of palletized goods, reducing manual labor and minimizing errors.

- Internet of Things (IoT): IoT devices can monitor environmental conditions such as temperature and humidity, ensuring sensitive goods are transported under optimal conditions.

- Blockchain Technology: Blockchain enhances security and traceability by providing a decentralized ledger for recording shipment data, reducing the risk of fraud and improving accountability.

- Artificial Intelligence (AI): AI-driven analytics can optimize routing, predict shipment delays, and enhance decision-making processes within the logistics network.

These technological advancements not only improve operational efficiency but also provide businesses with valuable insights to optimize their shipping strategies.

For more information on logistics technology, visit the Supply Chain Digital platform.

Future Trends and Innovations in Palletized Shipping

The palletized shipping industry is poised for significant transformations driven by emerging trends and innovations. Anticipated developments include:

- Drone Delivery: Autonomous drones may revolutionize last-mile delivery, offering faster and more cost-effective transportation for small and time-sensitive shipments.

- Electric Trucks: The adoption of electric vehicles in freight transportation can reduce carbon emissions and operational costs, contributing to more sustainable shipping practices.

- Blockchain Integration: Enhanced traceability and security through blockchain can streamline transactions and improve trust across the supply chain.

- Advanced Robotics: Robotics and automation can further optimize warehouse operations, from palletizing goods to loading and unloading shipments.

- Sustainable Pallet Materials: Innovations in eco-friendly pallet materials, such as recyclable plastics and sustainable wood alternatives, can reduce the environmental impact of palletized shipping.

- Smart Pallets: Equipped with sensors and IoT technology, smart pallets can provide real-time data on shipment conditions, enhancing monitoring and management capabilities.

These advancements are expected to drive greater efficiency, sustainability, and adaptability in palletized shipping, making it an increasingly attractive option for businesses aiming to stay competitive in a dynamic market.

Stay updated with the latest trends by following industry leaders and publications such as Logistics Management.