Understanding Hazmat Shipping Regulations and Compliance

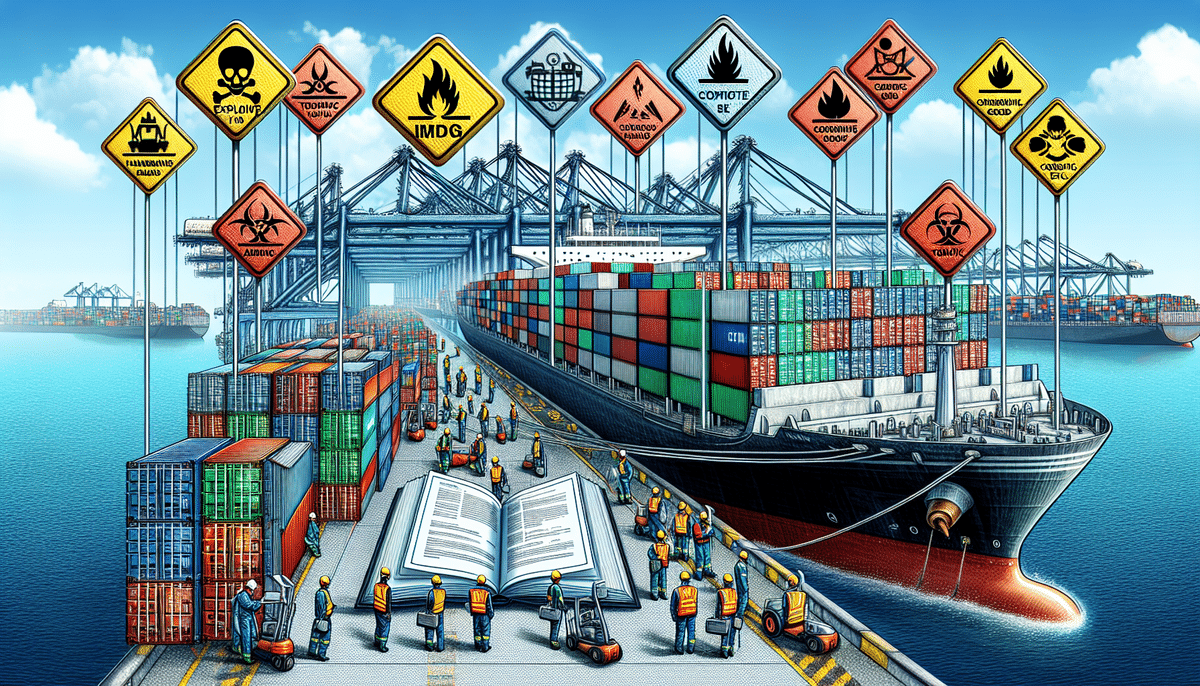

Shipping hazardous materials (hazmat) involves navigating a complex landscape of regulations to ensure safety and compliance. Key regulatory bodies include the U.S. Department of Transportation (DOT), the International Air Transport Association (IATA), and the International Maritime Organization (IMO) IMDG Code. These organizations establish guidelines that vary based on the type of material, transportation mode, and destination.

Non-compliance can lead to severe penalties, including hefty fines, legal action, and potential environmental harm. For instance, the DOT can impose fines up to $75,000 per day for violations of hazardous materials regulations. Ensuring adherence to these regulations not only avoids legal repercussions but also protects individuals and the environment from the dangers posed by hazardous materials.

Identification and Classification of Hazardous Materials

Proper identification and classification are foundational steps in hazmat shipping. Hazardous materials are categorized into nine classes, including:

- Explosives

- Gases

- Flammable Liquids

- Flammable Solids

- Oxidizing Substances

- Toxic and Infectious Substances

- Radioactive Materials

- Corrosives

- Miscellaneous Dangerous Goods

Accurate classification ensures that materials are handled, packaged, and transported according to their specific risks. The Pipeline and Hazardous Materials Safety Administration (PHMSA) provides detailed guidance on classification standards.

Packaging and Labeling Requirements for Hazmat Products

Proper packaging and labeling are critical for the safe transport of hazardous materials. Packaging must meet the standards set by regulatory agencies, ensuring that containers are suitable for the material's hazard class and packing group. Common packaging types include:

- Drums

- Cylinders

- Intermediate Bulk Containers (IBCs)

Labels and markings must clearly indicate the hazard class, identification numbers, and any necessary handling instructions. The Federal Aviation Administration (FAA) provides specific labeling requirements for air transport to enhance safety and emergency response effectiveness.

Essential Documentation for Hazmat Shipping

Accurate documentation is essential for compliance and safety in hazmat shipping. Required documents typically include:

- Shipping Papers: Detailing the contents, hazard class, and emergency response information.

- Permits and Certificates: Depending on the material and mode of transport.

- Material Safety Data Sheets (MSDS): Providing detailed information on handling and emergency measures.

Regulatory agencies often mandate the retention of shipping documentation for specific periods, such as the DOT's requirement to keep records for two years. Proper documentation ensures traceability and accountability throughout the shipping process.

Selecting Appropriate Shipping Containers for Hazardous Materials

The choice of shipping container significantly impacts the safety and compliance of hazmat transport. Factors to consider include the material's physical properties, transportation mode, and regulatory requirements. Common containers are:

- Drums: Suitable for liquids and solids.

- Cylinders: Ideal for gases.

- Intermediate Bulk Containers (IBCs): Used for larger volumes.

Containers must comply with standards set by bodies like the DOT and IATA, ensuring they are robust enough to prevent leaks and withstand transportation stresses. The International Maritime Organization provides guidelines for container specifications under the IMDG Code.

Best Practices for Handling and Transporting Hazmat

Implementing best practices ensures the safe and efficient transport of hazardous materials. Key practices include:

- Compliance: Regularly update procedures to align with the latest regulations.

- Proper Packaging and Labeling: Use appropriate containers and clear labels.

- Training: Ensure all personnel are trained in handling, packaging, and emergency response.

- Communication: Maintain clear communication with carriers and stakeholders about the nature and handling requirements of the materials.

Adhering to these practices minimizes risks and enhances the safety of all parties involved in the transportation process.

Incident Response Planning for Hazmat Shipping

Preparedness for potential incidents is crucial in hazmat shipping. An effective incident response plan should include:

- Procedures for assessing and containing spills or accidents.

- Designated incident commanders to coordinate responses.

- Access to necessary personal protective equipment (PPE).

- Coordination with local emergency services and environmental agencies.

Regular training and drills ensure that all personnel are familiar with the response protocols, enhancing readiness and effectiveness in the event of an incident.

Avoiding Common Mistakes in Hazmat Shipping

Shipping hazardous materials comes with potential pitfalls that can lead to safety hazards and regulatory violations. Common mistakes include:

- Incorrectly identifying or classifying materials.

- Using improper packaging or labeling.

- Inadequate documentation and record-keeping.

- Insufficient training for personnel.

- Failure to stay updated with changing regulations.

Addressing these issues through comprehensive training, regular audits, and collaboration with regulatory experts can significantly reduce the risk of errors and enhance compliance.

Partnering with Qualified Hazmat Shipping Experts

Given the complexities of hazmat shipping, partnering with experienced experts can provide significant benefits. Qualified partners offer:

- Expertise in regulatory compliance and documentation.

- Advanced packaging and labeling solutions.

- Comprehensive training programs for personnel.

- Robust incident response planning and support.

Collaborating with specialists ensures that all aspects of hazmat shipping are managed effectively, reducing risks and enhancing operational efficiency.

Future Trends in the Hazmat Shipping Industry

The hazmat shipping industry is evolving with advancements in technology and increasing regulatory demands. Key trends include:

- Automation and Digital Tracking: Utilizing IoT and blockchain for real-time monitoring and enhanced traceability.

- Enhanced Safety Measures: Adoption of advanced materials and smart packaging solutions to improve safety.

- Stricter Regulations: Implementation of more rigorous standards to ensure environmental protection and public safety.

- Sustainability Initiatives: Focus on reducing the environmental footprint of hazmat transport through greener practices.

Staying informed about these trends enables businesses to adapt and maintain compliance in a dynamic regulatory environment.

The Cost of Non-Compliance with Hazmat Regulations

Non-compliance with hazmat regulations can have severe financial and reputational impacts. Potential costs include:

- Fines and Penalties: Regulatory bodies impose significant fines for violations, which can escalate with repeated offenses.

- Legal Consequences: Non-compliance may result in lawsuits and legal actions.

- Operational Disruptions: Incidents or regulatory actions can halt operations, leading to loss of business.

- Reputational Damage: Negative publicity can erode customer trust and affect market position.

Investing in compliance measures is essential to avoid these costs and ensure the sustainable operation of hazmat shipping activities.

The Importance of Training in Safe Hazmat Handling and Transport

Comprehensive training is critical for the safe handling and transport of hazardous materials. Effective training programs should cover:

- Regulatory requirements and compliance protocols.

- Proper packaging, labeling, and documentation procedures.

- Use of personal protective equipment (PPE).

- Emergency response and incident management.

Ongoing training and periodic updates ensure that personnel remain proficient in the latest safety practices and regulatory changes, fostering a culture of safety and compliance within the organization.

In conclusion, shipping hazardous materials requires meticulous attention to regulations, proper classification, packaging, and documentation, as well as robust training and incident response planning. By adhering to best practices, avoiding common mistakes, and partnering with qualified experts, businesses can ensure the safe and compliant transport of hazardous materials.