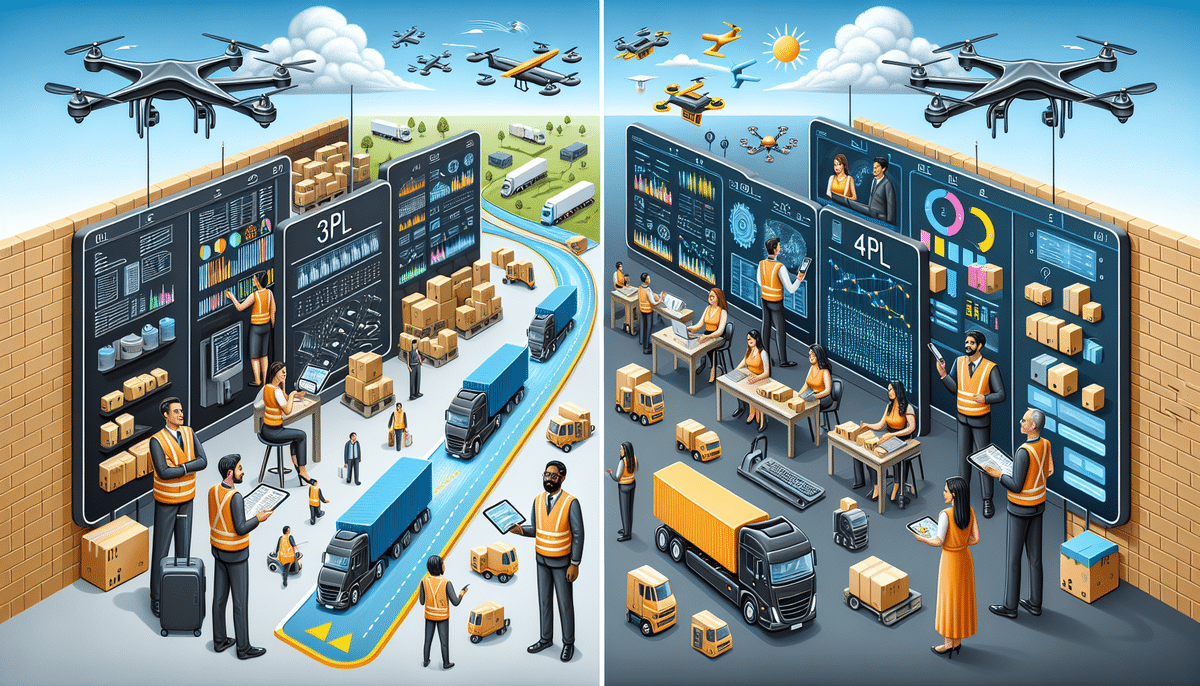

Understanding 3PL and 4PL Logistics: A Comprehensive Guide

If you're involved in the world of logistics, you've likely come across the terms "3PL" and "4PL." These acronyms refer to different logistics models that businesses can use to outsource their supply chain management. But what exactly do they mean, and what are the differences between them? Let's take a closer look.

Basics of Logistics and Outsourcing Models

What is Logistics?

At its core, logistics encompasses the processes involved in planning, implementing, and controlling the movement of goods and materials from one location to another. This includes everything from transportation and storage to inventory management and order fulfillment. Effective logistics management can help businesses reduce costs by up to 20%, improve customer satisfaction, and gain a competitive advantage in the market (Logistics Management).

Different Logistics Models

- First-Party Logistics (1PL): When a company manages its own logistics in-house.

- Second-Party Logistics (2PL): When a company contracts with a partner to handle specific logistics operations.

- Third-Party Logistics (3PL): When a company outsources some or all of its logistics operations to a third-party provider.

- Fourth-Party Logistics (4PL): When a company outsources its entire logistics function to a single organization that manages all aspects of the supply chain.

Each logistics model has its own advantages and disadvantages. For example, 1PL may offer more control and customization but can be more expensive and time-consuming to manage. On the other hand, 3PL and 4PL can provide cost savings and expertise but may result in less control over the logistics process. It's important for companies to carefully evaluate their needs and goals before choosing a logistics model.

In-Depth Comparison of 3PL and 4PL Logistics

Defining 3PL and 4PL

Third-Party Logistics (3PL) involves contracting with a provider to handle specific logistics functions, such as transportation or warehousing. The company retains some level of control over these operations, while the third-party provider manages them.

Fourth-Party Logistics (4PL) takes outsourcing a step further by allowing a single organization to manage the entire logistics function. This provider acts as a central point of control, overseeing all aspects of the supply chain, from transportation and warehousing to inventory management and order fulfillment. The company provides input but relinquishes a greater level of control to the 4PL provider.

Key Differences

- Control: 3PL offers partial control over specific logistics functions, whereas 4PL provides comprehensive management of the entire supply chain.

- Scope of Services: 3PL focuses on individual logistics services, while 4PL integrates all logistics activities into a unified strategy.

- Cost: 4PL services are generally more expensive due to the extensive coordination and management involved.

Ultimately, the choice between 3PL and 4PL depends on a company's specific needs, size, and the complexity of its supply chain.

Advantages and Disadvantages of 3PL vs. 4PL

3PL Logistics

Advantages:

- Flexibility to choose which logistics operations to outsource

- Access to third-party expertise and advanced technology

- Greater control over specific aspects of the supply chain

Disadvantages:

- Less streamlined supply chain management

- Potentially more complex to manage relationships with multiple providers

4PL Logistics

Advantages:

- Streamlined supply chain management with a single point of contact

- Enhanced coordination and integration across all logistics activities

- Comprehensive visibility and control over the entire supply chain

Disadvantages:

- Less control over specific logistics functions

- Potentially higher costs due to extensive management and coordination

When deciding between 3PL and 4PL, consider factors such as the size of your company, the complexity of your supply chain, and your budget. Regularly evaluating your logistics strategy ensures it continues to meet your evolving business needs.

The Role of Technology in 3PL and 4PL Logistics

Technology is a crucial component in both 3PL and 4PL logistics. Third-party logistics providers utilize a range of technologies, including Transportation Management Systems (TMS) and Warehouse Management Systems (WMS), to optimize operations. Fourth-party logistics providers leverage technology to integrate and manage all aspects of the supply chain through a centralized platform.

Key Technological Benefits

- Increased Visibility: Real-time tracking and monitoring provide up-to-date information on shipments and inventory, enhancing customer satisfaction and decision-making (Forbes).

- Automation: Automating routine tasks such as order processing, invoicing, and inventory management reduces errors, saves time, and improves overall efficiency.

- Data Analytics: Advanced analytics enable logistics providers to optimize routes, manage inventory more effectively, and predict future demand.

Emerging technologies like artificial intelligence, machine learning, and blockchain are further revolutionizing the logistics industry by enhancing transparency, efficiency, and security.

Selecting the Right Logistics Model for Your Business

Factors to Consider

- Business Size: Smaller businesses with simpler logistics needs may benefit more from the flexibility of 3PL, while larger businesses with complex supply chains might find 4PL more suitable.

- Supply Chain Complexity: If your supply chain involves multiple stages and partners, a 4PL provider can offer comprehensive management and integration.

- Budget: Consider the cost implications of each model. While 4PL can be more expensive, the streamlined operations may provide long-term cost savings.

- Control and Flexibility: Determine how much control you want to retain over your logistics operations versus the benefits of outsourcing management.

Evaluating Providers

When selecting a logistics provider, consider the following:

- Industry Experience: Ensure the provider has expertise in your specific industry and understands its unique challenges.

- Technology Capabilities: Look for providers that utilize advanced technologies to enhance efficiency and visibility.

- Scalability: Choose a provider that can scale with your business growth and adapt to changing logistics needs.

- Reputation and References: Check the provider’s track record, client testimonials, and case studies to assess their reliability and effectiveness.

Future Trends in 3PL and 4PL Logistics

The logistics industry is continuously evolving, driven by technological advancements and changing market demands. Here are some key trends shaping the future of 3PL and 4PL logistics:

- Artificial Intelligence and Machine Learning: These technologies are enabling predictive analytics, optimizing routes, and enhancing decision-making processes.

- Blockchain: Blockchain technology is improving transparency, security, and efficiency in supply chain transactions.

- Internet of Things (IoT): IoT devices provide real-time data on shipments, inventory, and equipment, enhancing visibility and control.

- Sustainability: There is a growing emphasis on sustainable logistics practices, including the use of eco-friendly transportation and reducing carbon footprints.

- Automation and Robotics: Automated warehouses and the use of robotics are streamlining operations and reducing labor costs.

According to a report by Statista, the global logistics market is expected to grow to over $12 trillion by 2027, driven by these technological advancements and the increasing demand for efficient supply chain solutions.

Case Studies: Successful 3PL and 4PL Implementations

Here are a few examples of companies that have successfully leveraged 3PL and 4PL logistics to streamline their operations:

- Procter & Gamble: The consumer goods giant has utilized 4PL logistics to coordinate demand planning, production scheduling, and transportation across its complex global supply chain.

- CVS Health: The pharmacy chain outsourced its logistics operations to a 3PL provider to optimize transportation and distribution for its pharmaceutical products.

- Dell: The computer manufacturer has employed 3PL logistics to manage its global supply chain, from raw materials to finished products, improving efficiency and reducing costs.

Cost Comparison Between 3PL and 4PL Logistics

The costs associated with 3PL and 4PL logistics can vary widely based on your specific requirements, provider, and industry. Generally, 4PL logistics tend to be more expensive due to the increased level of coordination and management involved. However, the benefits of streamlined supply chain management can often offset these costs over time by reducing inefficiencies and improving overall performance.

According to a Statista report, the global 3PL market was valued at approximately $1.6 trillion in 2022 and is projected to grow at a CAGR of 8.5% from 2023 to 2028. This growth is driven by increasing demand for logistics services, globalization of supply chains, and advancements in technology.

Evaluating the Impact of Outsourcing on Your Supply Chain Management

Outsourcing your logistics operations can significantly impact your supply chain management. Both 3PL and 4PL logistics offer benefits in terms of efficiency, cost savings, and performance improvement, but they also come with certain challenges and drawbacks. By carefully considering your needs, goals, and resources, you can make an informed decision about which logistics model is right for your business.

Conducting a Cost-Benefit Analysis

Perform a thorough cost-benefit analysis to understand the financial implications of outsourcing. Consider both direct costs (fees paid to the provider) and indirect costs (potential loss of control, integration challenges).

Consulting Stakeholders

Engage with stakeholders across your organization to gather insights and ensure that the chosen logistics model aligns with overall business objectives.

Reviewing Provider Capabilities

Evaluate potential logistics providers by reviewing their capabilities, client testimonials, and case studies to ensure they can meet your specific needs.

By following these steps, you can effectively evaluate the impact of outsourcing and choose a logistics model that enhances your supply chain management.