Advantages of Digital Printing for Branded Boxes

Digital printing has become a game-changer in the production of branded boxes, offering a range of benefits that surpass traditional printing methods like flexography and lithography. This section delves into the key advantages that make digital printing the preferred choice for businesses aiming to enhance their packaging solutions.

Versatility in Production Runs

One of the standout advantages of digital printing is its ability to handle both small and large-scale production runs with equal efficiency. Unlike traditional methods that require costly setup processes for large orders, digital printing eliminates the need for printing plates, allowing businesses to produce small batches quickly and economically.

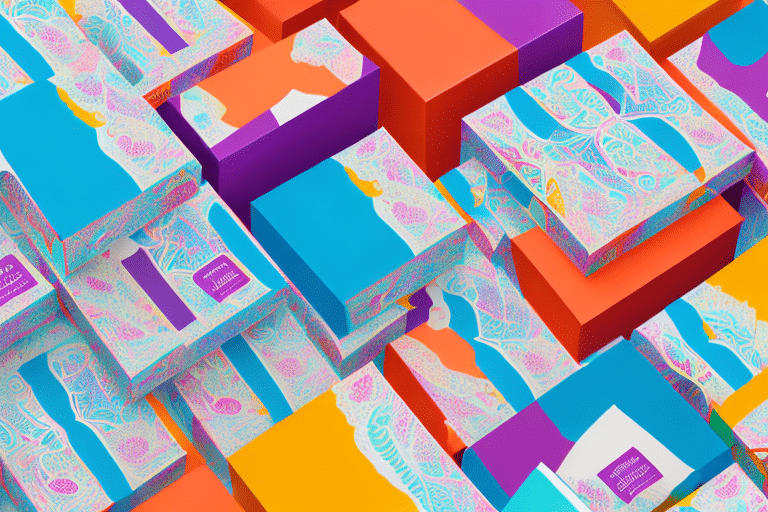

High-Resolution Graphics and Images

Digital printing supports high-resolution imagery, enabling businesses to incorporate vibrant colors, intricate details, and complex designs into their branded boxes. This capability ensures that the packaging is not only functional but also visually appealing, effectively capturing consumer attention on store shelves.

Faster Turnaround Times

Time is of the essence in today’s fast-paced market. Digital printing significantly reduces production times by streamlining the printing process. With minimal setup requirements, businesses can move from design to finished product in a matter of days, allowing for quicker responses to market trends and consumer demands.

Cost-Effectiveness

Digital printing offers a more cost-effective solution compared to traditional methods, especially for short runs and customized orders. The elimination of printing plates reduces initial costs, and the ability to print on-demand minimizes waste, leading to overall cost savings for businesses.

Environmental Benefits of Digital Printing

The shift towards sustainable business practices has made environmental considerations a top priority for many companies. Digital printing aligns with these values by offering eco-friendly advantages that help reduce the environmental impact of packaging production.

Reduced Waste and Resource Consumption

Digital printing minimizes waste by allowing for precise production runs tailored to actual demand. This on-demand capability reduces excess inventory and the associated environmental footprint from overproduction.

Eco-Friendly Materials and Processes

Digital printing often utilizes water-based inks and recyclable materials, further decreasing the environmental impact. The absence of chemical development processes in digital printing also means fewer hazardous substances are released into the environment.

Energy Efficiency

Digital printing machines are generally more energy-efficient than traditional printing presses. Lower energy consumption contributes to a smaller carbon footprint, supporting businesses in their sustainability goals.

Customization and Personalization Options

In an era where personalized experiences are highly valued, digital printing offers unparalleled customization options for branded boxes. This level of personalization can enhance customer engagement and brand loyalty.

Tailored Designs for Target Audiences

Digital printing allows businesses to create packaging that resonates with specific target audiences. By customizing colors, graphics, and messages, companies can ensure that their packaging appeals directly to their desired consumer base.

Variable Data Printing

With variable data printing, each branded box can feature unique information such as customer names, special offers, or personalized messages. This technique not only enhances the customer experience but also opens avenues for targeted marketing strategies.

Flexible Design Changes

Unlike traditional printing methods that require significant effort to change designs, digital printing enables quick and easy alterations. This flexibility allows businesses to update their packaging designs in response to changing market trends or promotional campaigns without incurring additional costs.

Cost Benefits of Digital Printing

Digital printing presents substantial cost advantages for businesses, making it a financially prudent choice for both small and large-scale production runs.

Economical for Small Batches

For businesses that require limited quantities of branded boxes, digital printing offers an affordable solution without the need for expensive setup fees associated with traditional printing methods.

Scalability for Large Orders

When scaling up production, digital printing maintains cost-effectiveness by reducing labor and material expenses. The streamlined process ensures that larger orders do not disproportionately increase production costs.

Maximizing Return on Investment (ROI)

By enabling efficient production, reducing waste, and allowing for targeted marketing through personalization, digital printing helps businesses maximize their ROI. Investing in digital printing technology can lead to long-term savings and increased profitability.

Applications of Digital Printing in Branded Boxes

Digital printing is versatile and can be applied across various industries to create distinctive branded boxes that serve both functional and marketing purposes.

Cosmetics and Beauty Products

In the cosmetics industry, packaging plays a crucial role in conveying luxury and sophistication. Digital printing allows for high-definition images and intricate designs that enhance the perceived value of beauty products.

Food and Beverage Packaging

For food and beverage companies, packaging must not only protect the product but also entice consumers visually. Digital printing enables the creation of appealing and informative packaging that can highlight product features and branding effectively.

Electronics and Gadgets

In the competitive electronics market, branded boxes need to stand out with sleek and modern designs. Digital printing facilitates the use of sharp graphics and innovative layouts that reflect the cutting-edge nature of electronic products.

Retail and E-commerce

Retailers and e-commerce businesses benefit from digital printing through the ability to produce customized and seasonal packaging. This adaptability helps in creating a memorable unboxing experience that can drive customer satisfaction and repeat business.

Future Trends in Digital Printing Technology

As technology continues to advance, the future of digital printing in the packaging industry looks promising. Emerging trends are set to enhance capabilities and further establish digital printing as the standard for branded box production.

Advancements in Printing Materials

Developments in sustainable and innovative materials are expanding the possibilities for digital printing. New substrates and eco-friendly options are being introduced, allowing businesses to explore creative packaging solutions while adhering to environmental standards.

Integration with Smart Packaging

The integration of digital printing with smart packaging features, such as QR codes and NFC technology, is gaining traction. These innovations enable interactive customer experiences and provide additional value through information accessibility and engagement.

Enhanced Automation and AI

The incorporation of automation and artificial intelligence in digital printing processes is improving efficiency and precision. AI-driven design tools and automated workflows are streamlining production, reducing errors, and enabling more sophisticated customization options.

Augmented Reality (AR) Integration

Augmented Reality is being integrated into packaging designs through digital printing, creating interactive experiences for consumers. AR-enabled packaging can provide immersive brand storytelling and product information, enhancing the overall customer experience.

Case Studies: Successful Branding with Digital Printed Boxes

Numerous businesses have harnessed the power of digital printing to elevate their branding strategies. These case studies highlight the tangible benefits and innovative approaches that have led to successful outcomes.

Cosmetics Company: Enhancing Brand Appeal

A leading cosmetics company utilized digital printing to create vibrant and eye-catching packaging that differentiated its products from competitors. The high-resolution graphics and customizable designs resulted in increased shelf appeal and boosted sales by 15% within six months.

Food and Beverage Company: Boosting Brand Recognition

A food and beverage company implemented digital printed branded boxes featuring unique designs and personalized messages. This strategy not only improved brand recognition but also fostered customer loyalty, contributing to a 20% increase in repeat purchases.

Electronics Manufacturer: Streamlining Packaging Processes

An electronics manufacturer adopted digital printing to streamline its packaging production. The ability to quickly produce custom packaging for various product lines reduced lead times by 30% and lowered production costs by 25%, enhancing overall operational efficiency.

Conclusion

Digital printing has firmly established itself as the preferred method for producing high-quality branded boxes across diverse industries. Its numerous advantages—from cost-effectiveness and customization capabilities to environmental sustainability—make it an invaluable tool for businesses seeking to enhance their packaging and branding efforts. As technology continues to evolve, digital printing is poised to offer even more innovative solutions, ensuring that branded boxes remain a critical component of successful brand strategies. Embracing digital printing not only meets the current demands of the market but also positions businesses for future growth and success.